Question: case study A 'Door'able Solutions needed Peter Simms sat at his desk looking over the numbers. He was a bit surprised by the numbers that

case study

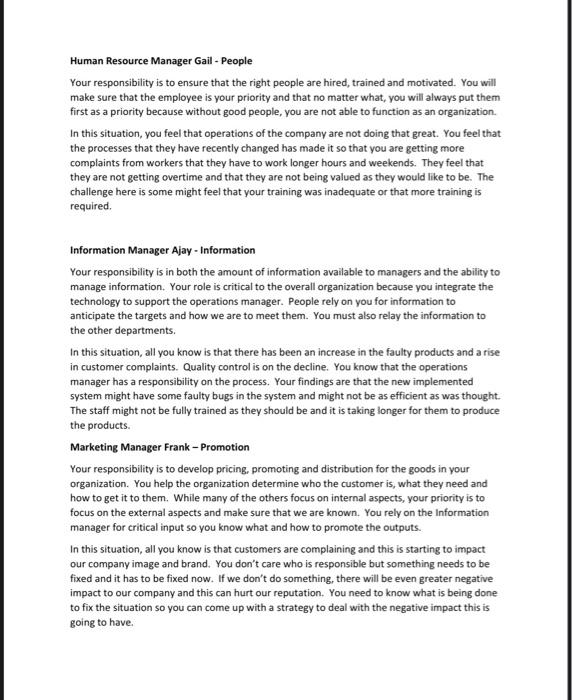

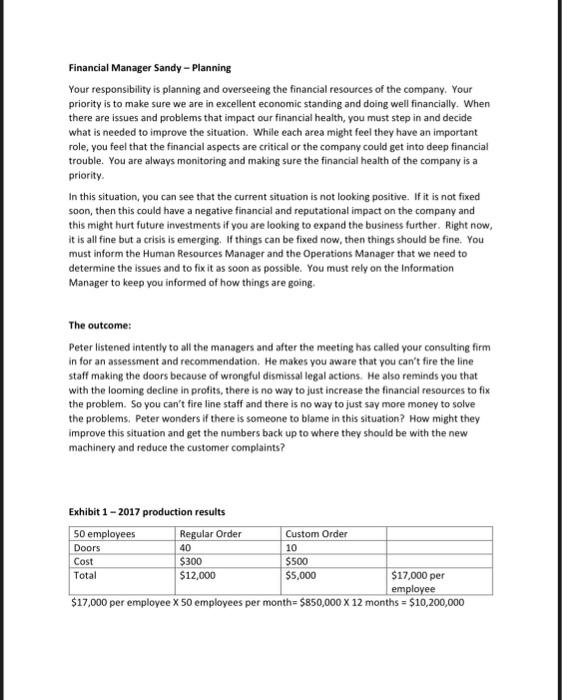

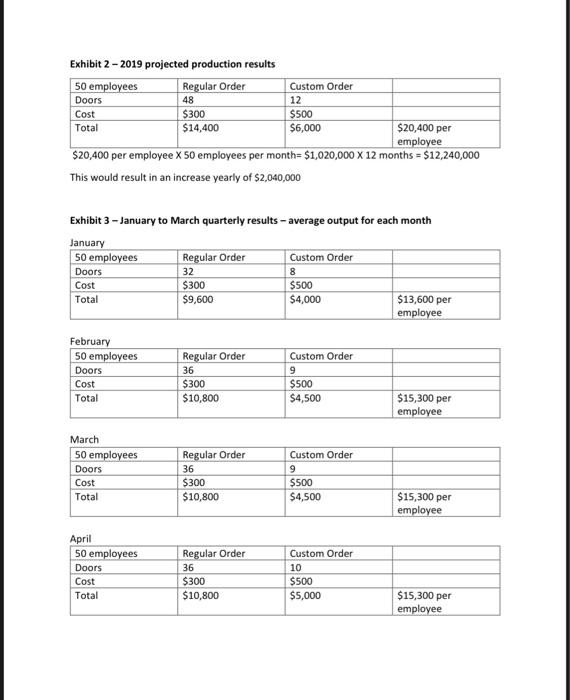

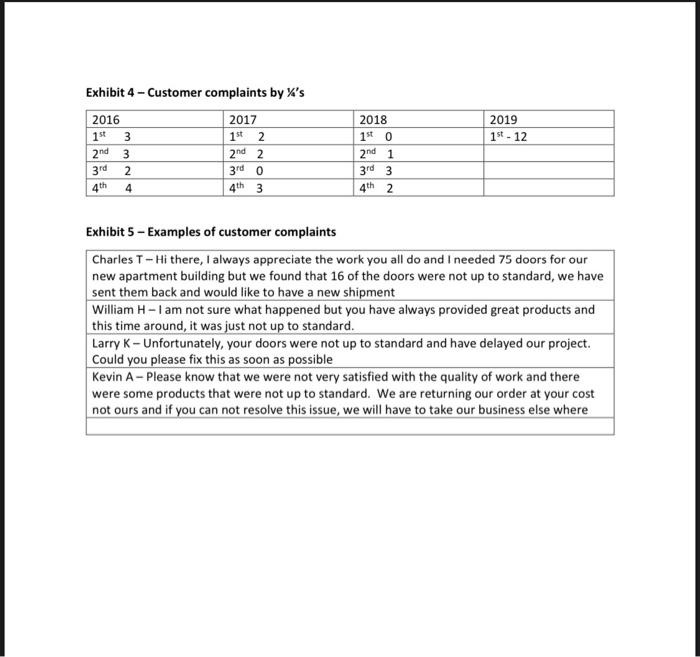

A 'Door'able Solutions needed Peter Simms sat at his desk looking over the numbers. He was a bit surprised by the numbers that the last quarter results were showing. "Weren't the efficiency numbers supposed to go up?" he thought. "We just spent about $1.4 million on new equipment and machinery to make our production speeds go up so the results should be higher. Peter had called a meeting of his senior team to try and figure out what was going on. Background At the age of 45, Peter was the CEO of Adoorable Manufacturing'. The company was in the business of making doors for residential homes. He started the company from scratch at the age of 30 years old. He had spent many years in the wood working industry. At 16, he was in high school and lugging 2X4's and other beams at Jamie's Lumberyard. It was difficult summer work but he enjoyed it. He was always interested in woodwork and would always be tinkering and building birdhouses, small furniture and other related wood products. Eventually, the projects got more complicated and he got more familiar with more complicated machinery When he was about 25 years old, he got his first real woodworking job at 'Wood Works'. Here he got to learn to use more complicated machinery and the importance of quality and consistency of the product. Here, they were more into mass producing furniture and home items. He had initiative and quickly rose to the level of shop foreman and he was overseeing about 5 employees As time passed, Peter got better at his work but more importantly, he got to better understand the woodworking industry and how to run a business. He did some evening classes at school to brush up on his management skills and eventually, decided to start his own small company called "Adorable Manufacturing when he was only 30 years old. He would run it and hired a couple of people to help with the orders and making the doors. One of the original employees was Kurt and he still is with 'Adoorable Doors'. They would only make doors and door frames for residential housing to keep things simple. He thought that if they concentrate in one area of construction, it would make their work more efficient and they could get really great at it Slowly as the years went by, the company grew. What started out to be a small company of three employees grew to where the company now has 60 employees. There are 50 line staff who make the doors, 5 managers for the various areas of Human Resources, Information, Finance/Accounting, Marketing and Operations, and 5 clerical staff who can take orders, process orders and help the managers and CEO on the daily functions. The current line staff making doors range in age and experience. Kurt is the oldest and he has been with the company since it started 15 years ago. Kurt has an established routine and likes to keep things going the way they are. Gail on the other hand, has recently started about a year ago and has come from a trade school where they taught her how to use some of the latest machinery. The other employees ranged in age and experience levels. For a number of years, things were progressing along and the sales were consistent. Their brand grew and grew and they were shipping doors all across Canada and the United States. Part of the reason for their success is the ability of the company to do a quick turn around on regular door orders and they could make 40 regular doors using the standard machinery per employee/per month. There were also customized door requests as well and if it was a customized orders, that would take more time and they could do 10 of those a month for each employee. Also, there was a solid reputation on their brand and customers knew that the quality was great and customer service issues were handled promptly and positively. Regular door costs were $300 each and the custom orders would cost $500 each. From a revenue standpoint, if things were consistent that was beneficial (see exhibit 1). Based on the machinery they had been using this was the capacity and they could not increase production any further. A new opportunity In June 2018, Peter called in Glenn Frost into his office. Glenn was the Manager for Operations and was responsible for the machinery and making sure things were progressing along smoothly. Peter and Glenn had a conversation about the capacity and if they were to invest in new machinery, Peter asked, "would that make things more efficient and increase production?" Glenn said that he would look around and investigate and get back to him. By August 2018, Glenn called another meeting with Peter and said that he had found similar machinery at 'Do Better Machines' that was more modern and should be able to increase production by 20% capacity and their representative would include training in the purchase. This would mean that the production would now increase to a greater level and provided the numbers and there was a projection of 2019 results (see exhibit 2). This would mean in an increase yearly revenue of $2.4 million. That sounded like a great number and the machinery would cost $1.4 million and take about 3 months or so to fully be installed and operational. That means January 2019 would be the change over to the new machinery. The old machinery could be still used but with everyone being trained on the new machinery, eventually, it was decided to get rid of the old machinery Peter then called his management team of Glenn, who was Operations, Gail Evans who was the Human Resources Manager, Frank Jones who was the Marketing Manager, Ajay Sangha who was the Information Manager and Sandy Chu who was the Manager of Finance. He advised them that Glenn had come up with the vendor for the new machinery and that we would all need to work together to make this happen. He turned to Sandy and said that we need to allocate the funding and seek out the way to purchase the equipment and that she needed to work with Glenn on the sale of the old equipment. Sandy said that she would put the proposal together and ensure that Glenn and Peter were aware of how this would be funded. Peter consulted with his Human Resources Manager Gail Evans. Gail was responsible for the wellbeing of the employees and training. Peter said, "Gail, you will need to lead the training with the representative from 'Do Better Machines so that the employees are comfortable using the new machines." He then turned to Ajay and said, "You must also be involved so that the information is provided to the front line staff making doors. Ajay said that he could do that and come up with the required details after he talks to Glenn in Operations and Gail in Human Resources. Finally, Peter turned to Frank and said that since he was the Marketing Manager and responsible for customer service, that Frank would need to keep everyone informed on new markets since production would increase and to make sure the customers were happy with the production quality. It seemed that the wheels were in motion on this new venture and all left the meeting excited with the opportunity Over the next couple of months, "Do Better Machines" came in and installed the new machines. Their representative spent a week having the workers take shifts and training so the work could still be done and that the employees would be better informed and able to use the new machinery. Some of the older employees grumbled that they did not really want to change machinery because they were used to the old ones and the younger employees seemed to appreciate the newer advanced machines. The managers were aware but thought that it would just take a bit of extra time to train everyone and get them up to speed so that they were now exceeding the old production numbers. What Happened?: It was now May 2019 and the first quarter results were pulled together by the management team and presented to Peter. He sat there in disbelief. The numbers did not seem to add up! Not only did the production results indicate no increase in production, the numbers actually went down initially and then seemed to stabilize at the lower numbers (see exhibit 3). Added to this was the increase in the number of doors returned and the customer complaints. Not only were we not meeting production numbers, but now we had doors returned with minor deficiencies that did not meet the standards that the customers wanted. The returned doors did not meet the customer specifications or had minor issues and could still be sold to individuals or small contractors but first, 'Adoorable' needed to have some minor adjustments done. The challenge though was the customer complaints because these could damage the reputation of the company and they could lose customers if things were not careful. The company need to fix these issues and fast (see exhibit 4). Peter was confused by the results and got a more detailed report. He got a breakdown of all the employees and output. He found that generally, the older employees had a reduction in output and the younger employees had a significantly higher production output. It seems that either the older employees were not comfortable on the new machinery or maybe they were no longer as motivated because of the change. All Peter knew is that the door output numbers had gone down and stabilized at unacceptable numbers and now he was even thinking if the new machinery was a good idea in the first place. What about training, did the training happen the way it was supposed to? Was the information about the change provided to everyone in the organization? Peter decided that it was time to do something and he called a meeting of the managers to try and figure out what was going on and how to fix things. Peter has hired your company to attend the meeting and to understand the situation and to make recommendations on what should be done to fix things so that they are doing better and meeting the numbers that they should with the new machinery. Prior to this meeting, your team has met with each manager and some of the employees to get a sense of the situation. The Marketing Manager has also provided you the feedback and comments from the customers who said that the overall production quality was not up to standard and returned the doors (see exhibit 5). So now you have the numbers not matching the output that should have been and returned doors that are in the warehouse and you have to figure out what to do with them and a declining reputation with some of your customers. After speaking with some of the employees, you also know some of the older employees feel that the machinery makes it more difficult to output the products and that some corners might be cut so that they are trying to keep up with the demands but that it should not be impacting the quality. They feel that the old machinery was fine and they would have liked to have kept it the way it was. The meeting: A meeting has been called by Peter and all of the management team are to attend and share their understanding of the situation. Each of the people in the meeting have an area of importance and priorities. Some times these priorities might conflict with others in the organization. You are aware of each person's concern. Each area shares their information: Operations Manager Peter - Process Your responsibility for the running of the company's inputs and outputs. You control how the work flows. Your priority is to ensure that what ever the targets established by the company must be met regardless of the situations that occur. This might mean people have to work longer hours or on weekends during challenging times. We all must contribute to the overall objectives of the organization, In this situation, with a rising number of faulty outputs, some people are looking at your area as the area that needs to be fixed. You know that it is not a machinery issue because there are no maintenance problems. You feel it is an employee issue and feel that human resources is either not training staff properly or hiring people who might not be the best fit. You need to then convince the Human Resources Manager that they need to fix the system. had gone down and stabilized at unacceptable numbers and now he was even thinking if the new machinery was a good idea in the first place. What about training, did the training happen the way it was supposed to? Was the information about the change provided to everyone in the organization? Peter decided that it was time to do something and he called a meeting of the managers to try and figure out what was going on and how to fix things. Peter has hired your company to attend the meeting and to understand the situation and to make recommendations on what should be done to fix things so that they are doing better and meeting the numbers that they should with the new machinery. Prior to this meeting, your team has met with each manager and some of the employees to get a sense of the situation. The Marketing Manager has also provided you the feedback and comments from the customers who said that the overall production quality was not up to standard and returned the doors (see exhibit 5). So now you have the numbers not matching the output that should have been and returned doors that are in the warehouse and you have to figure out what to do with them and a declining reputation with some of your customers. After speaking with some of the employees, you also know some of the older employees feel that the machinery makes it more difficult to output the products and that some corners might be cut so that they are trying to keep up with the demands but that it should not be impacting the quality. They feel that the old machinery was fine and they would have liked to have kept it the way it was. The meeting: A meeting has been called by Peter and all of the management team are to attend and share their understanding of the situation. Each of the people in the meeting have an area of importance and priorities. Some times these priorities might conflict with others in the organization. You are aware of each person's concern. Each area shares their information: Operations Manager Peter - Process Your responsibility for the running of the company's inputs and outputs. You control how the work flows. Your priority is to ensure that what ever the targets established by the company must be met regardless of the situations that occur. This might mean people have to work longer hours or on weekends during challenging times. We all must contribute to the overall objectives of the organization, In this situation, with a rising number of faulty outputs, some people are looking at your area as the area that needs to be fixed. You know that it is not a machinery issue because there are no maintenance problems. You feel it is an employee issue and feel that human resources is either not training staff properly or hiring people who might not be the best fit. You need to then convince the Human Resources Manager that they need to fix the system. Human Resource Manager Gail - People Your responsibility is to ensure that the right people are hired, trained and motivated. You will make sure that the employee is your priority and that no matter what you will always put them first as a priority because without good people, you are not able to function as an organization. In this situation, you feel that operations of the company are not doing that great. You feel that the processes that they have recently changed has made it so that you are getting more complaints from workers that they have to work longer hours and weekends. They feel that they are not getting overtime and that they are not being valued as they would like to be. The challenge here is some might feel that your training was inadequate or that more training is required Information Manager Ajay - Information Your responsibility is in both the amount of information available to managers and the ability to manage information. Your role is critical to the overall organization because you integrate the technology to support the operations manager. People rely on you for information to anticipate the targets and how we are to meet them. You must also relay the information to the other departments In this situation, all you know is that there has been an increase in the faulty products and a rise in customer complaints. Quality control is on the decline. You know that the operations manager has a responsibility on the process. Your findings are that the new implemented system might have some faulty bugs in the system and might not be as efficient as was thought. The staff might not be fully trained as they should be and it is taking longer for them to produce the products. Marketing Manager Frank - Promotion Your responsibility is to develop pricing, promoting and distribution for the goods in your organization. You help the organization determine who the customer is what they need and how to get it to them. While many of the others focus on internal aspects, your priority is to focus on the external aspects and make sure that we are known. You rely on the Information manager for critical input so you know what and how to promote the outputs. In this situation, all you know is that customers are complaining and this is starting to impact our company image and brand. You don't care who is responsible but something needs to be fixed and it has to be fixed now. If we don't do something, there will be even greater negative impact to our company and this can hurt our reputation. You need to know what is being done to fix the situation so you can come up with a strategy to deal with the negative impact this is going to have Financial Manager Sandy - Planning Your responsibility is planning and overseeing the financial resources of the company. Your priority is to make sure we are in excellent economic standing and doing well financially. When there are issues and problems that impact our financial health, you must step in and decide what is needed to improve the situation. While each area might feel they have an important role, you feel that the financial aspects are critical or the company could get into deep financial trouble. You are always monitoring and making sure the financial health of the company is a priority In this situation, you can see that the current situation is not looking positive. If it is not fixed soon, then this could have a negative financial and reputational impact on the company and this might hurt future investments if you are looking to expand the business further. Right now, it is all fine but a crisis is emerging. If things can be fixed now, then things should be fine. You must inform the Human Resources Manager and the Operations Manager that we need to determine the issues and to fix it as soon as possible. You must rely on the Information Manager to keep you informed of how things are going The outcome: Peter listened intently to all the managers and after the meeting has called your consulting firm in for an assessment and recommendation. He makes you aware that you can't fire the line staff making the doors because of wrongful dismissal legal actions. He also reminds you that with the looming decline in profits, there is no way to just increase the financial resources to fix the problem. So you can't fire line staff and there is no way to just say more money to solve the problems. Peter wonders if there is someone to blame in this situation? How might they improve this situation and get the numbers back up to where they should be with the new machinery and reduce the customer complaints? Exhibit 1 - 2017 production results 50 employees Regular Order Custom Order Doors 40 10 Cost $300 $500 Total $12,000 $5,000 $17,000 per employee $17,000 per employee X 50 employees per month= $850,000 X 12 months = $10,200,000 Cost Exhibit 2 - 2019 projected production results 50 employees Regular Order Custom Order Doors 48 12 $300 $500 Total $14,400 $6,000 $20,400 per employee $20,400 per employee X 50 employees per month= $1,020,000 X 12 months = $12,240,000 This would result in an increase yearly of $2,000,000 Exhibit 3 - January to March quarterly results - average output for each month January 50 employees Regular Order Custom Order Doors 32 Cost $300 $500 Total $9,600 $4,000 $13,600 per employee 8 February 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 9 $500 $4,500 $15,300 per employee March 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 9 $500 $4,500 $15,300 per employee April 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 10 $500 $5,000 $15,300 per employee Exhibit 4 - Customer complaints by K's 2016 2017 13 1st 2 2nd 3 2nd 2 3rd 2 3rd 0 4th 4 4th 3 2019 1st - 12 2018 1st 0 2nd 1 3rd 3 4th 2 Exhibit 5 Examples of customer complaints Charles T - Hi there, I always appreciate the work you all do and I needed 75 doors for our new apartment building but we found that 16 of the doors were not up to standard, we have sent them back and would like to have a new shipment William H - I am not sure what happened but you have always provided great products and this time around, it was just not up to standard. Larry K - Unfortunately, your doors were not up to standard and have delayed our project. Could you please fix this as soon as possible Kevin A - Please know that we were not very satisfied with the quality of work and there were some products that were not up to standard. We are returning our order at your cost not ours and if you can not resolve this issue, we will have to take our business else where A 'Door'able Solutions needed Peter Simms sat at his desk looking over the numbers. He was a bit surprised by the numbers that the last quarter results were showing. "Weren't the efficiency numbers supposed to go up?" he thought. "We just spent about $1.4 million on new equipment and machinery to make our production speeds go up so the results should be higher. Peter had called a meeting of his senior team to try and figure out what was going on. Background At the age of 45, Peter was the CEO of Adoorable Manufacturing'. The company was in the business of making doors for residential homes. He started the company from scratch at the age of 30 years old. He had spent many years in the wood working industry. At 16, he was in high school and lugging 2X4's and other beams at Jamie's Lumberyard. It was difficult summer work but he enjoyed it. He was always interested in woodwork and would always be tinkering and building birdhouses, small furniture and other related wood products. Eventually, the projects got more complicated and he got more familiar with more complicated machinery When he was about 25 years old, he got his first real woodworking job at 'Wood Works'. Here he got to learn to use more complicated machinery and the importance of quality and consistency of the product. Here, they were more into mass producing furniture and home items. He had initiative and quickly rose to the level of shop foreman and he was overseeing about 5 employees As time passed, Peter got better at his work but more importantly, he got to better understand the woodworking industry and how to run a business. He did some evening classes at school to brush up on his management skills and eventually, decided to start his own small company called "Adorable Manufacturing when he was only 30 years old. He would run it and hired a couple of people to help with the orders and making the doors. One of the original employees was Kurt and he still is with 'Adoorable Doors'. They would only make doors and door frames for residential housing to keep things simple. He thought that if they concentrate in one area of construction, it would make their work more efficient and they could get really great at it Slowly as the years went by, the company grew. What started out to be a small company of three employees grew to where the company now has 60 employees. There are 50 line staff who make the doors, 5 managers for the various areas of Human Resources, Information, Finance/Accounting, Marketing and Operations, and 5 clerical staff who can take orders, process orders and help the managers and CEO on the daily functions. The current line staff making doors range in age and experience. Kurt is the oldest and he has been with the company since it started 15 years ago. Kurt has an established routine and likes to keep things going the way they are. Gail on the other hand, has recently started about a year ago and has come from a trade school where they taught her how to use some of the latest machinery. The other employees ranged in age and experience levels. For a number of years, things were progressing along and the sales were consistent. Their brand grew and grew and they were shipping doors all across Canada and the United States. Part of the reason for their success is the ability of the company to do a quick turn around on regular door orders and they could make 40 regular doors using the standard machinery per employee/per month. There were also customized door requests as well and if it was a customized orders, that would take more time and they could do 10 of those a month for each employee. Also, there was a solid reputation on their brand and customers knew that the quality was great and customer service issues were handled promptly and positively. Regular door costs were $300 each and the custom orders would cost $500 each. From a revenue standpoint, if things were consistent that was beneficial (see exhibit 1). Based on the machinery they had been using this was the capacity and they could not increase production any further. A new opportunity In June 2018, Peter called in Glenn Frost into his office. Glenn was the Manager for Operations and was responsible for the machinery and making sure things were progressing along smoothly. Peter and Glenn had a conversation about the capacity and if they were to invest in new machinery, Peter asked, "would that make things more efficient and increase production?" Glenn said that he would look around and investigate and get back to him. By August 2018, Glenn called another meeting with Peter and said that he had found similar machinery at 'Do Better Machines' that was more modern and should be able to increase production by 20% capacity and their representative would include training in the purchase. This would mean that the production would now increase to a greater level and provided the numbers and there was a projection of 2019 results (see exhibit 2). This would mean in an increase yearly revenue of $2.4 million. That sounded like a great number and the machinery would cost $1.4 million and take about 3 months or so to fully be installed and operational. That means January 2019 would be the change over to the new machinery. The old machinery could be still used but with everyone being trained on the new machinery, eventually, it was decided to get rid of the old machinery Peter then called his management team of Glenn, who was Operations, Gail Evans who was the Human Resources Manager, Frank Jones who was the Marketing Manager, Ajay Sangha who was the Information Manager and Sandy Chu who was the Manager of Finance. He advised them that Glenn had come up with the vendor for the new machinery and that we would all need to work together to make this happen. He turned to Sandy and said that we need to allocate the funding and seek out the way to purchase the equipment and that she needed to work with Glenn on the sale of the old equipment. Sandy said that she would put the proposal together and ensure that Glenn and Peter were aware of how this would be funded. Peter consulted with his Human Resources Manager Gail Evans. Gail was responsible for the wellbeing of the employees and training. Peter said, "Gail, you will need to lead the training with the representative from 'Do Better Machines so that the employees are comfortable using the new machines." He then turned to Ajay and said, "You must also be involved so that the information is provided to the front line staff making doors. Ajay said that he could do that and come up with the required details after he talks to Glenn in Operations and Gail in Human Resources. Finally, Peter turned to Frank and said that since he was the Marketing Manager and responsible for customer service, that Frank would need to keep everyone informed on new markets since production would increase and to make sure the customers were happy with the production quality. It seemed that the wheels were in motion on this new venture and all left the meeting excited with the opportunity Over the next couple of months, "Do Better Machines" came in and installed the new machines. Their representative spent a week having the workers take shifts and training so the work could still be done and that the employees would be better informed and able to use the new machinery. Some of the older employees grumbled that they did not really want to change machinery because they were used to the old ones and the younger employees seemed to appreciate the newer advanced machines. The managers were aware but thought that it would just take a bit of extra time to train everyone and get them up to speed so that they were now exceeding the old production numbers. What Happened?: It was now May 2019 and the first quarter results were pulled together by the management team and presented to Peter. He sat there in disbelief. The numbers did not seem to add up! Not only did the production results indicate no increase in production, the numbers actually went down initially and then seemed to stabilize at the lower numbers (see exhibit 3). Added to this was the increase in the number of doors returned and the customer complaints. Not only were we not meeting production numbers, but now we had doors returned with minor deficiencies that did not meet the standards that the customers wanted. The returned doors did not meet the customer specifications or had minor issues and could still be sold to individuals or small contractors but first, 'Adoorable' needed to have some minor adjustments done. The challenge though was the customer complaints because these could damage the reputation of the company and they could lose customers if things were not careful. The company need to fix these issues and fast (see exhibit 4). Peter was confused by the results and got a more detailed report. He got a breakdown of all the employees and output. He found that generally, the older employees had a reduction in output and the younger employees had a significantly higher production output. It seems that either the older employees were not comfortable on the new machinery or maybe they were no longer as motivated because of the change. All Peter knew is that the door output numbers had gone down and stabilized at unacceptable numbers and now he was even thinking if the new machinery was a good idea in the first place. What about training, did the training happen the way it was supposed to? Was the information about the change provided to everyone in the organization? Peter decided that it was time to do something and he called a meeting of the managers to try and figure out what was going on and how to fix things. Peter has hired your company to attend the meeting and to understand the situation and to make recommendations on what should be done to fix things so that they are doing better and meeting the numbers that they should with the new machinery. Prior to this meeting, your team has met with each manager and some of the employees to get a sense of the situation. The Marketing Manager has also provided you the feedback and comments from the customers who said that the overall production quality was not up to standard and returned the doors (see exhibit 5). So now you have the numbers not matching the output that should have been and returned doors that are in the warehouse and you have to figure out what to do with them and a declining reputation with some of your customers. After speaking with some of the employees, you also know some of the older employees feel that the machinery makes it more difficult to output the products and that some corners might be cut so that they are trying to keep up with the demands but that it should not be impacting the quality. They feel that the old machinery was fine and they would have liked to have kept it the way it was. The meeting: A meeting has been called by Peter and all of the management team are to attend and share their understanding of the situation. Each of the people in the meeting have an area of importance and priorities. Some times these priorities might conflict with others in the organization. You are aware of each person's concern. Each area shares their information: Operations Manager Peter - Process Your responsibility for the running of the company's inputs and outputs. You control how the work flows. Your priority is to ensure that what ever the targets established by the company must be met regardless of the situations that occur. This might mean people have to work longer hours or on weekends during challenging times. We all must contribute to the overall objectives of the organization, In this situation, with a rising number of faulty outputs, some people are looking at your area as the area that needs to be fixed. You know that it is not a machinery issue because there are no maintenance problems. You feel it is an employee issue and feel that human resources is either not training staff properly or hiring people who might not be the best fit. You need to then convince the Human Resources Manager that they need to fix the system. had gone down and stabilized at unacceptable numbers and now he was even thinking if the new machinery was a good idea in the first place. What about training, did the training happen the way it was supposed to? Was the information about the change provided to everyone in the organization? Peter decided that it was time to do something and he called a meeting of the managers to try and figure out what was going on and how to fix things. Peter has hired your company to attend the meeting and to understand the situation and to make recommendations on what should be done to fix things so that they are doing better and meeting the numbers that they should with the new machinery. Prior to this meeting, your team has met with each manager and some of the employees to get a sense of the situation. The Marketing Manager has also provided you the feedback and comments from the customers who said that the overall production quality was not up to standard and returned the doors (see exhibit 5). So now you have the numbers not matching the output that should have been and returned doors that are in the warehouse and you have to figure out what to do with them and a declining reputation with some of your customers. After speaking with some of the employees, you also know some of the older employees feel that the machinery makes it more difficult to output the products and that some corners might be cut so that they are trying to keep up with the demands but that it should not be impacting the quality. They feel that the old machinery was fine and they would have liked to have kept it the way it was. The meeting: A meeting has been called by Peter and all of the management team are to attend and share their understanding of the situation. Each of the people in the meeting have an area of importance and priorities. Some times these priorities might conflict with others in the organization. You are aware of each person's concern. Each area shares their information: Operations Manager Peter - Process Your responsibility for the running of the company's inputs and outputs. You control how the work flows. Your priority is to ensure that what ever the targets established by the company must be met regardless of the situations that occur. This might mean people have to work longer hours or on weekends during challenging times. We all must contribute to the overall objectives of the organization, In this situation, with a rising number of faulty outputs, some people are looking at your area as the area that needs to be fixed. You know that it is not a machinery issue because there are no maintenance problems. You feel it is an employee issue and feel that human resources is either not training staff properly or hiring people who might not be the best fit. You need to then convince the Human Resources Manager that they need to fix the system. Human Resource Manager Gail - People Your responsibility is to ensure that the right people are hired, trained and motivated. You will make sure that the employee is your priority and that no matter what you will always put them first as a priority because without good people, you are not able to function as an organization. In this situation, you feel that operations of the company are not doing that great. You feel that the processes that they have recently changed has made it so that you are getting more complaints from workers that they have to work longer hours and weekends. They feel that they are not getting overtime and that they are not being valued as they would like to be. The challenge here is some might feel that your training was inadequate or that more training is required Information Manager Ajay - Information Your responsibility is in both the amount of information available to managers and the ability to manage information. Your role is critical to the overall organization because you integrate the technology to support the operations manager. People rely on you for information to anticipate the targets and how we are to meet them. You must also relay the information to the other departments In this situation, all you know is that there has been an increase in the faulty products and a rise in customer complaints. Quality control is on the decline. You know that the operations manager has a responsibility on the process. Your findings are that the new implemented system might have some faulty bugs in the system and might not be as efficient as was thought. The staff might not be fully trained as they should be and it is taking longer for them to produce the products. Marketing Manager Frank - Promotion Your responsibility is to develop pricing, promoting and distribution for the goods in your organization. You help the organization determine who the customer is what they need and how to get it to them. While many of the others focus on internal aspects, your priority is to focus on the external aspects and make sure that we are known. You rely on the Information manager for critical input so you know what and how to promote the outputs. In this situation, all you know is that customers are complaining and this is starting to impact our company image and brand. You don't care who is responsible but something needs to be fixed and it has to be fixed now. If we don't do something, there will be even greater negative impact to our company and this can hurt our reputation. You need to know what is being done to fix the situation so you can come up with a strategy to deal with the negative impact this is going to have Financial Manager Sandy - Planning Your responsibility is planning and overseeing the financial resources of the company. Your priority is to make sure we are in excellent economic standing and doing well financially. When there are issues and problems that impact our financial health, you must step in and decide what is needed to improve the situation. While each area might feel they have an important role, you feel that the financial aspects are critical or the company could get into deep financial trouble. You are always monitoring and making sure the financial health of the company is a priority In this situation, you can see that the current situation is not looking positive. If it is not fixed soon, then this could have a negative financial and reputational impact on the company and this might hurt future investments if you are looking to expand the business further. Right now, it is all fine but a crisis is emerging. If things can be fixed now, then things should be fine. You must inform the Human Resources Manager and the Operations Manager that we need to determine the issues and to fix it as soon as possible. You must rely on the Information Manager to keep you informed of how things are going The outcome: Peter listened intently to all the managers and after the meeting has called your consulting firm in for an assessment and recommendation. He makes you aware that you can't fire the line staff making the doors because of wrongful dismissal legal actions. He also reminds you that with the looming decline in profits, there is no way to just increase the financial resources to fix the problem. So you can't fire line staff and there is no way to just say more money to solve the problems. Peter wonders if there is someone to blame in this situation? How might they improve this situation and get the numbers back up to where they should be with the new machinery and reduce the customer complaints? Exhibit 1 - 2017 production results 50 employees Regular Order Custom Order Doors 40 10 Cost $300 $500 Total $12,000 $5,000 $17,000 per employee $17,000 per employee X 50 employees per month= $850,000 X 12 months = $10,200,000 Cost Exhibit 2 - 2019 projected production results 50 employees Regular Order Custom Order Doors 48 12 $300 $500 Total $14,400 $6,000 $20,400 per employee $20,400 per employee X 50 employees per month= $1,020,000 X 12 months = $12,240,000 This would result in an increase yearly of $2,000,000 Exhibit 3 - January to March quarterly results - average output for each month January 50 employees Regular Order Custom Order Doors 32 Cost $300 $500 Total $9,600 $4,000 $13,600 per employee 8 February 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 9 $500 $4,500 $15,300 per employee March 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 9 $500 $4,500 $15,300 per employee April 50 employees Doors Cost Total Regular Order 36 $300 $10,800 Custom Order 10 $500 $5,000 $15,300 per employee Exhibit 4 - Customer complaints by K's 2016 2017 13 1st 2 2nd 3 2nd 2 3rd 2 3rd 0 4th 4 4th 3 2019 1st - 12 2018 1st 0 2nd 1 3rd 3 4th 2 Exhibit 5 Examples of customer complaints Charles T - Hi there, I always appreciate the work you all do and I needed 75 doors for our new apartment building but we found that 16 of the doors were not up to standard, we have sent them back and would like to have a new shipment William H - I am not sure what happened but you have always provided great products and this time around, it was just not up to standard. Larry K - Unfortunately, your doors were not up to standard and have delayed our project. Could you please fix this as soon as possible Kevin A - Please know that we were not very satisfied with the quality of work and there were some products that were not up to standard. We are returning our order at your cost not ours and if you can not resolve this issue, we will have to take our business else where Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock