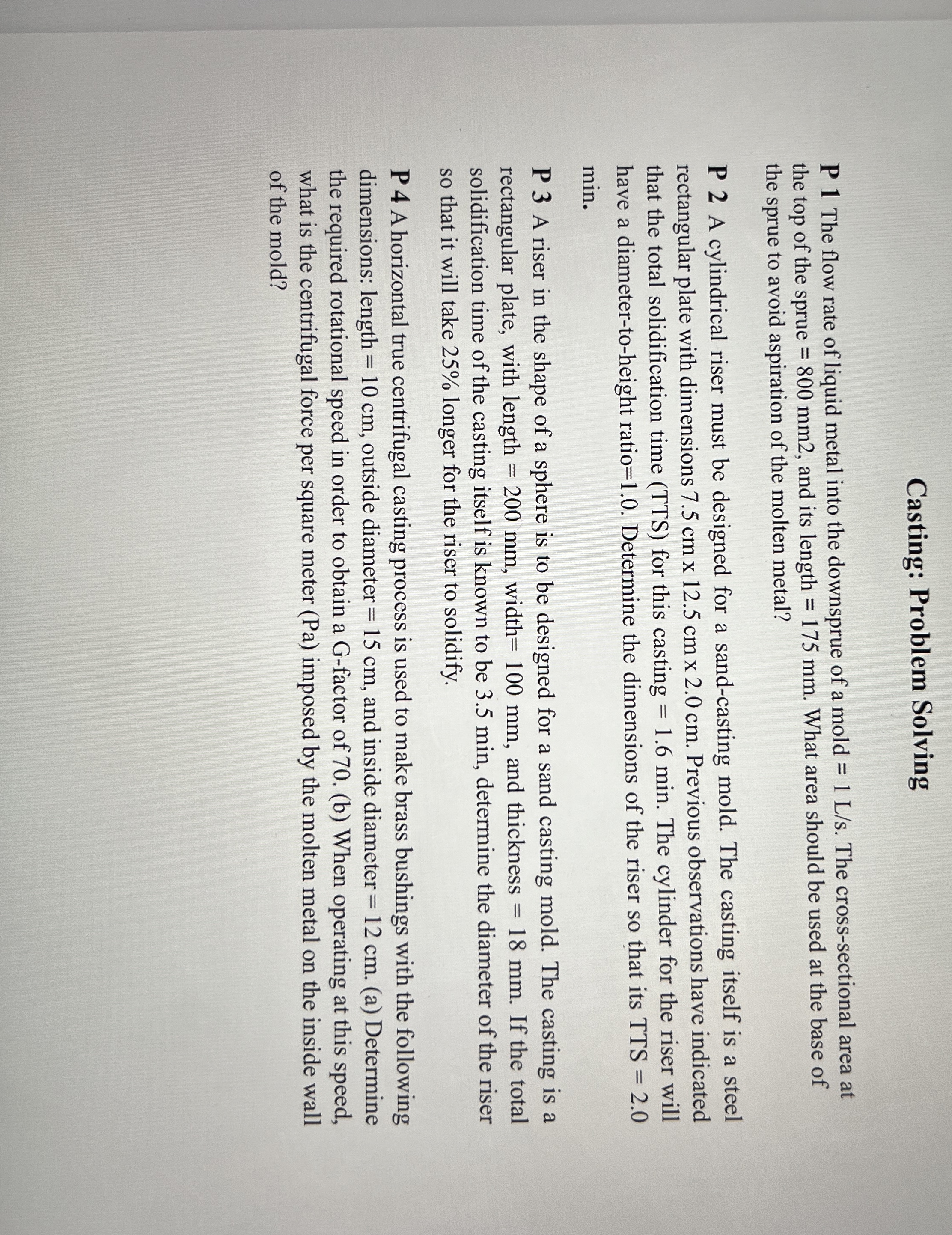

Question: Casting: Problem Solving P 1 The flow rate of liquid metal into the downsprue of a mold = 1 L s . The cross -

Casting: Problem Solving

P The flow rate of liquid metal into the downsprue of a mold The crosssectional area at

the top of the sprue and its length What area should be used at the base of

the sprue to avoid aspiration of the molten metal?

P A cylindrical riser must be designed for a sandcasting mold. The casting itself is a steel

rectangular plate with dimensions Previous observations have indicated

that the total solidification time TTS for this casting min. The cylinder for the riser will

have a diametertoheight ratio Determine the dimensions of the riser so that its TTS

min.

P A riser in the shape of a sphere is to be designed for a sand casting mold. The casting is a

rectangular plate, with length width and thickness If the total

solidification time of the casting itself is known to be min determine the diameter of the riser

so that it will take longer for the riser to solidify.

P A horizontal true centrifugal casting process is used to make brass bushings with the following

dimensions: length outside diameter and inside diameter a Determine

the required rotational speed in order to obtain a Gfactor of b When operating at this speed,

what is the centrifugal force per square meter Pa imposed by the molten metal on the inside wall

of the mold?

Solve all please

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock