Question: COURSE: OPERATION RESEARCH PLEASE TAKE YOUR TIME BUT MUST BE SOLVED COMPLETELY WITH ALL REQUIREMENTS PLEASE THANK YOU. I am sorry but there is no

COURSE: OPERATION RESEARCH

PLEASE TAKE YOUR TIME BUT MUST BE SOLVED COMPLETELY WITH ALL REQUIREMENTS PLEASE THANK YOU.

I am sorry but there is no more information about Question?

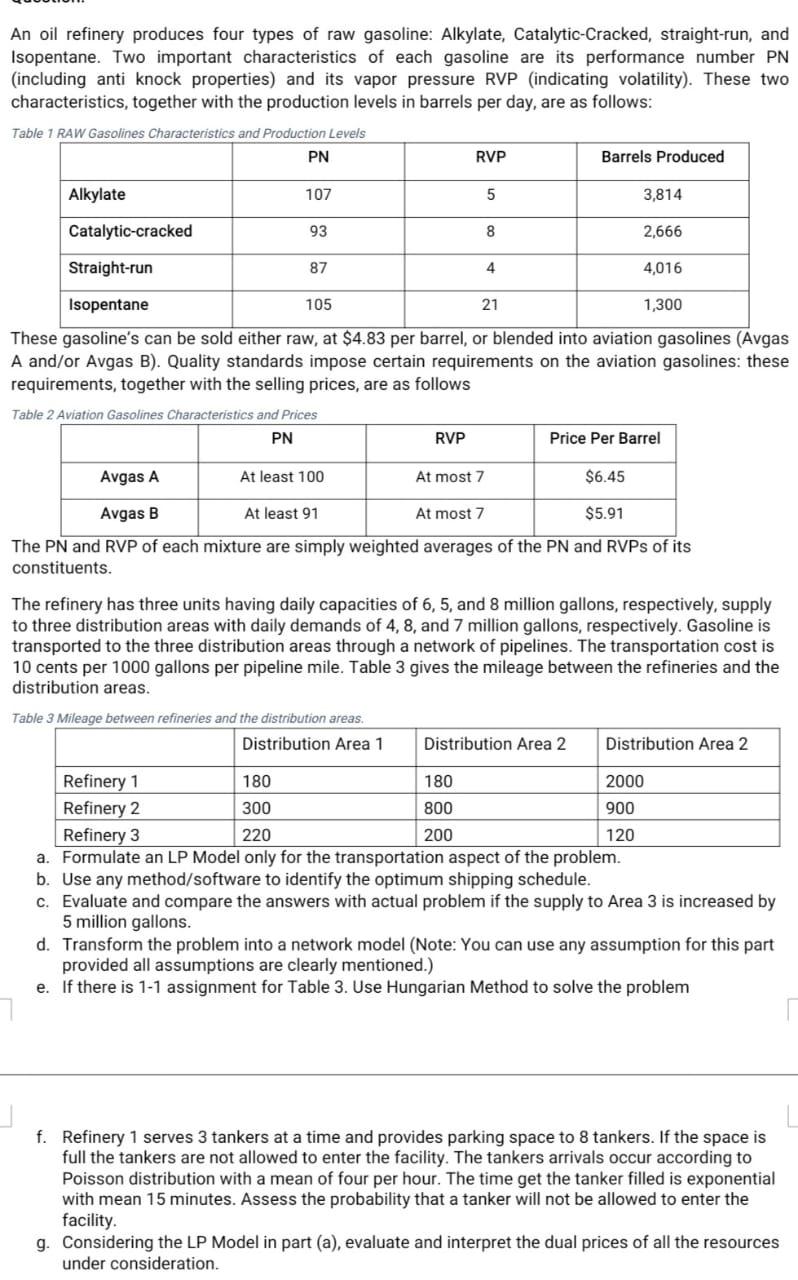

An oil refinery produces four types of raw gasoline: Alkylate, Catalytic-Cracked, straight-run, and Isopentane. Two important characteristics of each gasoline are its performance number PN (including anti knock properties) and its vapor pressure RVP (indicating volatility). These two characteristics, together with the production levels in barrels per day, are as follows: Table 1 RAW Gasolines Characteristics and Production Levels PN RVP Barrels Produced Alkylate 107 5 3,814 Catalytic-cracked 93 8 2,666 Straight-run 87 4 4,016 Isopentane 105 21 1,300 These gasoline's can be sold either raw, at $4.83 per barrel, or blended into aviation gasolines (Avgas A and/or Avgas B). Quality standards impose certain requirements on the aviation gasolines: these requirements, together with the selling prices, are as follows Table 2 Aviation Gasolines Characteristics and Prices PN RVP Price Per Barrel Avgas A At least 100 At most 7 $6.45 Avgas B At least 91 At most 7 $5.91 The PN and RVP of each mixture are simply weighted averages of the PN and RVPs of its constituents. The refinery has three units having daily capacities of 6, 5, and 8 million gallons, respectively, supply to three distribution areas with daily demands of 4, 8, and 7 million gallons, respectively. Gasoline is transported to the three distribution areas through a network of pipelines. The transportation cost is 10 cents per 1000 gallons per pipeline mile. Table 3 gives the mileage between the refineries and the distribution areas. Table 3 Mileage between refineries and the distribution areas. Distribution Area 1 Distribution Area 2 Distribution Area 2 Refinery 1 180 180 2000 Refinery2 300 800 900 Refinery 3 220 200 120 a. Formulate an LP Model only for the transportation aspect of the problem. b. Use any method/software to identify the optimum shipping schedule. c. Evaluate and compare the answers with actual problem if the supply to Area 3 is increased by 5 million gallons. d. Transform the problem into a network model (Note: You can use any assumption for this part provided all assumptions are clearly mentioned.) e. If there is 1-1 assignment for Table 3. Use Hungarian Method to solve the problem f. Refinery 1 serves 3 tankers at a time and provides parking space to 8 tankers. If the space is full the tankers are not allowed to enter the facility. The tankers arrivals occur according to Poisson distribution with a mean of four per hour. The time get the tanker filled is exponential with mean 15 minutes. Assess the probability that a tanker will not be allowed to enter the facility. g. Considering the LP Model in part (a), evaluate and interpret the dual prices of all the resources under considerationStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock