Question: Data Tronics Data Tronics assembles custom-printed circuit boards (PCBs) in small quantities. To process a particular order, the assembly line must first be set up

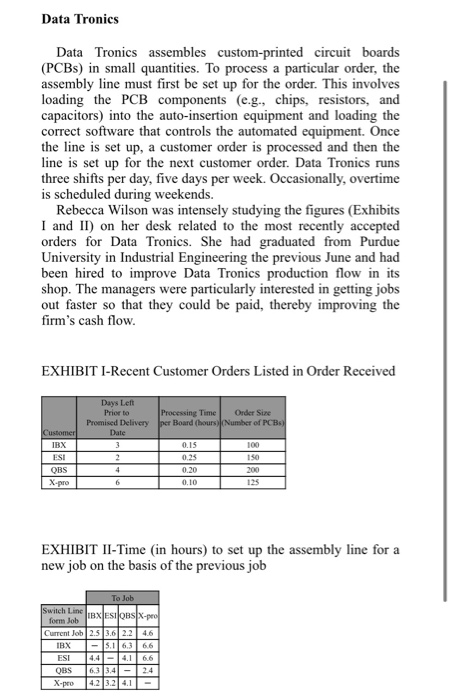

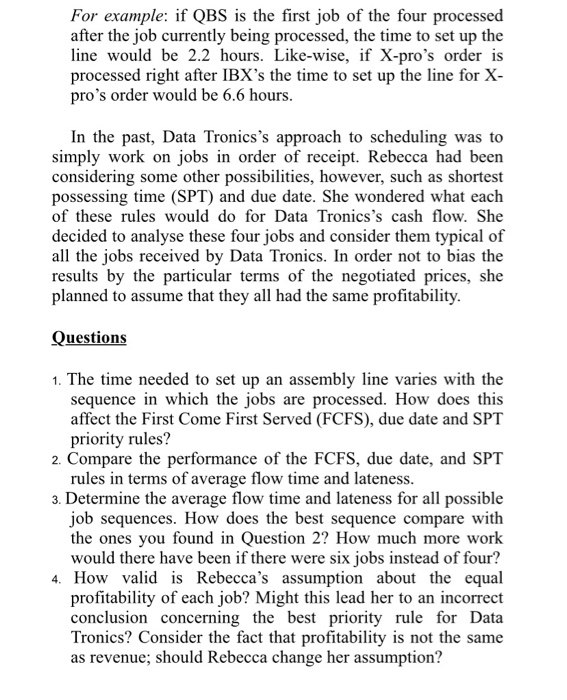

Data Tronics Data Tronics assembles custom-printed circuit boards (PCBs) in small quantities. To process a particular order, the assembly line must first be set up for the order. This involves loading the PCB components (e.g., chips, resistors, and capacitors) into the auto-insertion equipment and loading the correct software that controls the automated equipment. Once the line is set up, a customer order is processed and then the line is set up for the next customer order. Data Tronics runs three shifts per day, five days per week. Occasionally, overtime is scheduled during weekends. Rebecca Wilson was intensely studying the figures (Exhibits I and II) on her desk related to the most recently accepted orders for Data Tronics. She had graduated from Purdue University in Industrial Engineering the previous June and had been hired to improve Data Tronics production flow in its shop. The managers were particularly interested in getting jobs out faster so that they could be paid, thereby improving the firm's cash flow. EXHIBIT I-Recent Customer Orders Listed in Order Received Customer IBX ESI OBS X.pro Days Left Prior to Processing Time Order Size Promised Delivery per Board (hours) Number of PCB) Date 3 0.15 100 2 0.25 150 4 0.20 200 0.10 125 EXHIBIT II-Time (in hours) to set up the assembly line for a new job on the basis of the previous job To Job Switch Line form Job 1BXESTQBS X-Pro Current Job 2.5 3.6 2.2 4.6 IBX -5.1 6.3 6.6 ESI 4.41-14.1 6.6 OBS 6.3 3.4 - 2.4 X-pro 4.23.24.1 For example: if QBS is the first job of the four processed after the job currently being processed, the time to set up the line would be 2.2 hours. Like-wise, if X-pro's order is processed right after IBX's the time to set up the line for X- pro's order would be 6.6 hours. In the past, Data Tronics's approach to scheduling was to simply work on jobs in order of receipt. Rebecca had been considering some other possibilities, however, such as shortest possessing time (SPT) and due date. She wondered what each of these rules would do for Data Tronics's cash flow. She decided to analyse these four jobs and consider them typical of all the jobs received by Data Tronics. In order not to bias the results by the particular terms of the negotiated prices, she planned to assume that they all had the same profitability. Questions 1. The time needed to set up an assembly line varies with the sequence in which the jobs are processed. How does this affect the First Come First Served (FCFS), due date and SPT priority rules? 2. Compare the performance of the FCFS, due date, and SPT rules in terms of average flow time and lateness. 3. Determine the average flow time and lateness for all possible job sequences. How does the best sequence compare with the ones you found in Question 2? How much more work would there have been if there were six jobs instead of four? 4. How valid is Rebecca's assumption about the equal profitability of each job? Might this lead her to an incorrect conclusion concerning the best priority rule for Data Tronics? Consider the fact that profitability is not the same as revenue; should Rebecca change her assumption? Data Tronics Data Tronics assembles custom-printed circuit boards (PCBs) in small quantities. To process a particular order, the assembly line must first be set up for the order. This involves loading the PCB components (e.g., chips, resistors, and capacitors) into the auto-insertion equipment and loading the correct software that controls the automated equipment. Once the line is set up, a customer order is processed and then the line is set up for the next customer order. Data Tronics runs three shifts per day, five days per week. Occasionally, overtime is scheduled during weekends. Rebecca Wilson was intensely studying the figures (Exhibits I and II) on her desk related to the most recently accepted orders for Data Tronics. She had graduated from Purdue University in Industrial Engineering the previous June and had been hired to improve Data Tronics production flow in its shop. The managers were particularly interested in getting jobs out faster so that they could be paid, thereby improving the firm's cash flow. EXHIBIT I-Recent Customer Orders Listed in Order Received Customer IBX ESI OBS X.pro Days Left Prior to Processing Time Order Size Promised Delivery per Board (hours) Number of PCB) Date 3 0.15 100 2 0.25 150 4 0.20 200 0.10 125 EXHIBIT II-Time (in hours) to set up the assembly line for a new job on the basis of the previous job To Job Switch Line form Job 1BXESTQBS X-Pro Current Job 2.5 3.6 2.2 4.6 IBX -5.1 6.3 6.6 ESI 4.41-14.1 6.6 OBS 6.3 3.4 - 2.4 X-pro 4.23.24.1 For example: if QBS is the first job of the four processed after the job currently being processed, the time to set up the line would be 2.2 hours. Like-wise, if X-pro's order is processed right after IBX's the time to set up the line for X- pro's order would be 6.6 hours. In the past, Data Tronics's approach to scheduling was to simply work on jobs in order of receipt. Rebecca had been considering some other possibilities, however, such as shortest possessing time (SPT) and due date. She wondered what each of these rules would do for Data Tronics's cash flow. She decided to analyse these four jobs and consider them typical of all the jobs received by Data Tronics. In order not to bias the results by the particular terms of the negotiated prices, she planned to assume that they all had the same profitability. Questions 1. The time needed to set up an assembly line varies with the sequence in which the jobs are processed. How does this affect the First Come First Served (FCFS), due date and SPT priority rules? 2. Compare the performance of the FCFS, due date, and SPT rules in terms of average flow time and lateness. 3. Determine the average flow time and lateness for all possible job sequences. How does the best sequence compare with the ones you found in Question 2? How much more work would there have been if there were six jobs instead of four? 4. How valid is Rebecca's assumption about the equal profitability of each job? Might this lead her to an incorrect conclusion concerning the best priority rule for Data Tronics? Consider the fact that profitability is not the same as revenue; should Rebecca change her assumption