Question: Facility plan ning In an assembly plant, material handling between departments is performed using a uni- directional closed-loop conveyor. The figure below shows the layout

Facility planning

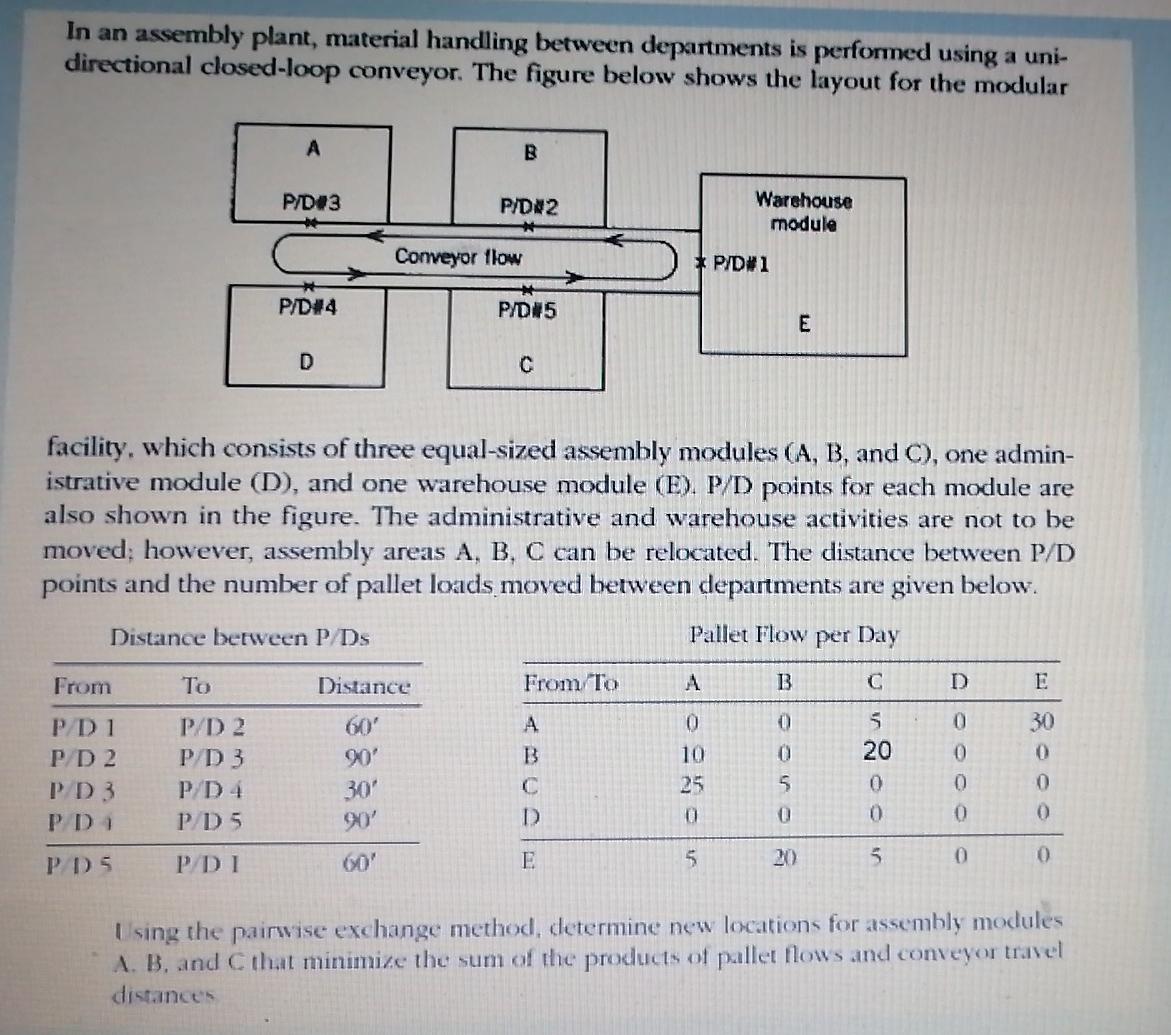

In an assembly plant, material handling between departments is performed using a uni- directional closed-loop conveyor. The figure below shows the layout for the modular A B P/DU3 P/DN2 Warehouse module Conveyor flow P/D# 1 P/D#4 P/DN5 E D facility, which consists of three equal-sized assembly modules (A, B, and C), one admin- istrative module (D), and one warehouse module (E). P/D points for each module are also shown in the figure. The administrative and warehouse activities are not to be moved; however, assembly areas A, B, C can be relocated. The distance between P/D points and the number of pallet loads moved between departments are given below. Distance between P Ds Pallet Flow per Day From To Distance From To B C D E 0 0 30 0 10 0 0 PD1 PD2 PD3 PD1 PAD 2 PD 3 PD4 PD 5 90' 30' 90' B C D 5 20 0 0 0 0 0 0 0 0 0 PDI PD 5 60' E 5 20) 5 0 0 Using the pairwise exchange method, determine new locations for assembly modules A. B. and C that minimize the sum of the products of pallet flows and conveyor travel distancesStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock