Question: I need a professional answer to this question I need a professional answer I need a professional answer = Homework: Portfolio 2 Part 3 (chapter

I need a professional answer to this question

I need a professional answer

I need a professional answer

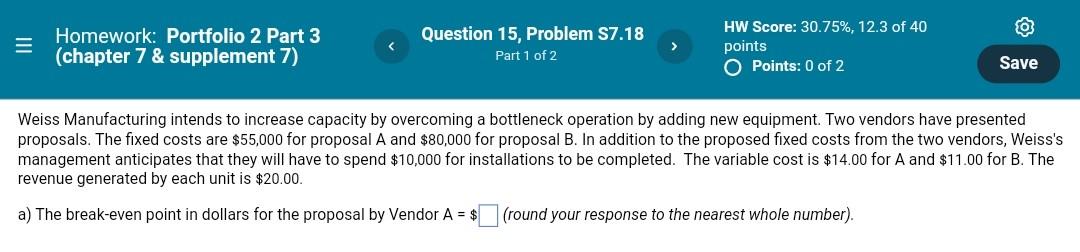

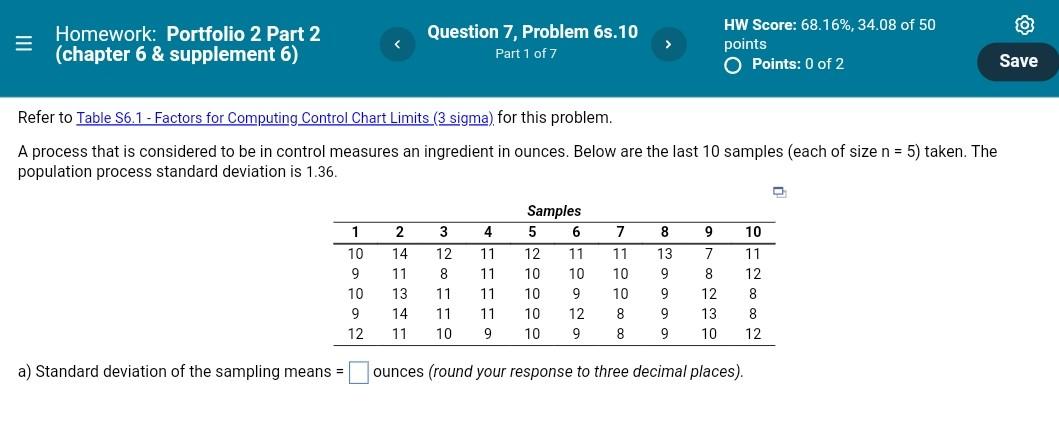

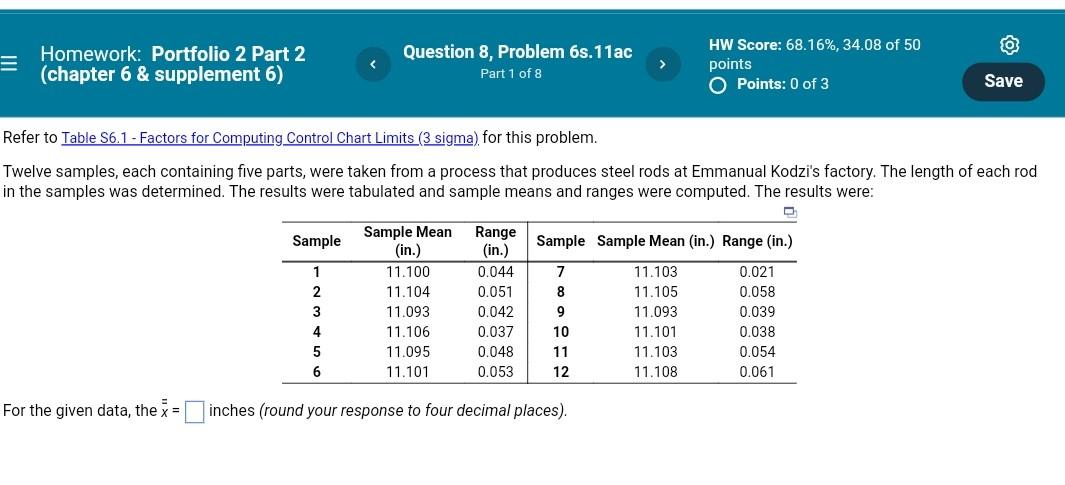

= Homework: Portfolio 2 Part 3 (chapter 7 & supplement 7) Question 15, Problem S7.18 Part 1 of 2 > HW Score: 30.75%, 12.3 of 40 points O Points: 0 of 2 Save Weiss Manufacturing intends to increase capacity by overcoming a bottleneck operation by adding new equipment. Two vendors have presented proposals. The fixed costs are $55,000 for proposal A and $80,000 for proposal B. In addition to the proposed fixed costs from the two vendors, Weiss's management anticipates that they will have to spend $10,000 for installations to be completed. The variable cost is $14.00 for A and $11.00 for B. The revenue generated by each unit is $20.00. a) The break-even point in dollars for the proposal by Vendor A = $ (round your response to the nearest whole number). = Homework: Portfolio 2 Part 2 (chapter 6 & supplement 6) Question 7, Problem 6s.10 Part 1 of 7 HW Score: 68.16%, 34.08 of 50 points O Points: 0 of 2 Save Refer to Table $6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. A process that is considered to be in control measures an ingredient in ounces. Below are the last 10 samples (each of size n = 5) taken. The population process standard deviation is 1.36. 1 10 10 9 10 9 12 2 14 11 13 14 11 3 12 8 11 11 10 4 11 11 11 11 9 Samples 5 6 12 11 10 10 10 9 9 10 12 10 9 9 7 11 10 10 8 8 8 13 9 9 9 9 9 7 8 12 13 10 11 12 8 8 12 a) Standard deviation of the sampling means = ounces (round your response to three decimal places). Homework: Portfolio 2 Part 2 (chapter 6 & supplement 6) Question 8, Problem 6s.11ac Part 1 of 8 HW Score: 68.16%, 34.08 of 50 points O Points: 0 of 3 Save Refer to Table S6,1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. Twelve samples, each containing five parts, were taken from a process that produces steel rods at Emmanual Kodzi's factory. The length of each rod in the samples was determined. The results were tabulated and sample means and ranges were computed. The results were: Sample Range (in.) Sample Sample Mean (in.) Range (in.) 0.044 7 Sample Mean (in.) 11.100 11.104 11.093 11.106 11.095 11.101 1 2 3 4 5 6 8 9 0.051 0.042 0.037 0.048 0.053 11.103 11.105 11.093 11.101 11.103 11.108 0.021 0.058 0.039 0.038 0.054 0.061 10 11 12 For the given data, the x = inches (round your response to four decimal places). = Homework: Portfolio 2 Part 3 (chapter 7 & supplement 7) Question 15, Problem S7.18 Part 1 of 2 > HW Score: 30.75%, 12.3 of 40 points O Points: 0 of 2 Save Weiss Manufacturing intends to increase capacity by overcoming a bottleneck operation by adding new equipment. Two vendors have presented proposals. The fixed costs are $55,000 for proposal A and $80,000 for proposal B. In addition to the proposed fixed costs from the two vendors, Weiss's management anticipates that they will have to spend $10,000 for installations to be completed. The variable cost is $14.00 for A and $11.00 for B. The revenue generated by each unit is $20.00. a) The break-even point in dollars for the proposal by Vendor A = $ (round your response to the nearest whole number). = Homework: Portfolio 2 Part 2 (chapter 6 & supplement 6) Question 7, Problem 6s.10 Part 1 of 7 HW Score: 68.16%, 34.08 of 50 points O Points: 0 of 2 Save Refer to Table $6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. A process that is considered to be in control measures an ingredient in ounces. Below are the last 10 samples (each of size n = 5) taken. The population process standard deviation is 1.36. 1 10 10 9 10 9 12 2 14 11 13 14 11 3 12 8 11 11 10 4 11 11 11 11 9 Samples 5 6 12 11 10 10 10 9 9 10 12 10 9 9 7 11 10 10 8 8 8 13 9 9 9 9 9 7 8 12 13 10 11 12 8 8 12 a) Standard deviation of the sampling means = ounces (round your response to three decimal places). Homework: Portfolio 2 Part 2 (chapter 6 & supplement 6) Question 8, Problem 6s.11ac Part 1 of 8 HW Score: 68.16%, 34.08 of 50 points O Points: 0 of 3 Save Refer to Table S6,1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. Twelve samples, each containing five parts, were taken from a process that produces steel rods at Emmanual Kodzi's factory. The length of each rod in the samples was determined. The results were tabulated and sample means and ranges were computed. The results were: Sample Range (in.) Sample Sample Mean (in.) Range (in.) 0.044 7 Sample Mean (in.) 11.100 11.104 11.093 11.106 11.095 11.101 1 2 3 4 5 6 8 9 0.051 0.042 0.037 0.048 0.053 11.103 11.105 11.093 11.101 11.103 11.108 0.021 0.058 0.039 0.038 0.054 0.061 10 11 12 For the given data, the x = inches (round your response to four decimal places)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts