Question: kdk It is a complete Question, It does not need more information. It is related to Project Management. I ONLY NEED REQUIREMENT 4 AND 5

kdk

kdk

It is a complete Question, It does not need more information. It is related to Project Management.

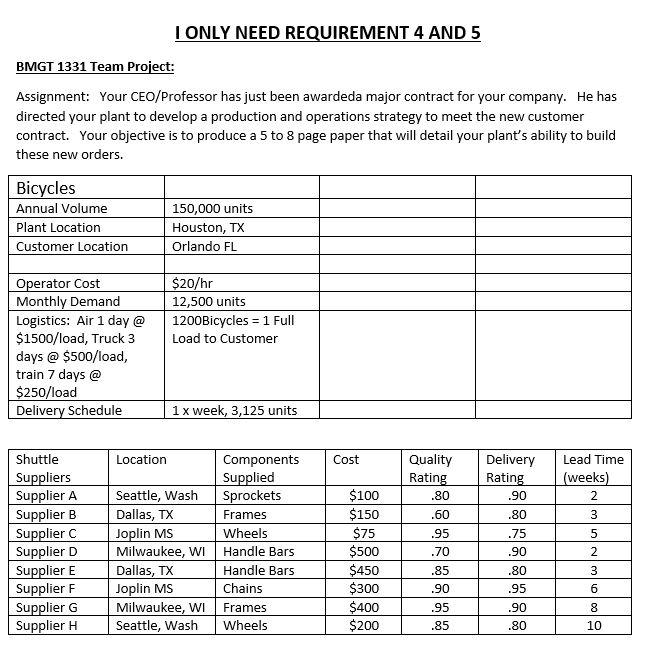

I ONLY NEED REQUIREMENT 4 AND 5 BMGT 1331 Team Project: Assignment: Your CEO/Professor has just been awardeda major contract for your company. He has directed your plant to develop a production and operations strategy to meet the new customer contract. Your objective is to produce a 5 to 8 page paper that will detail your plant's ability to build these new orders. Bicycles Annual Volume Plant Location Customer Location 150,000 units Houston, TX Orlando FL Operator Cost Monthly Demand Logistics: Air 1 day @ $1500/load, Truck 3 days @ $500/load, train 7 days @ $250/load Delivery Schedule $20/hr 12,500 units 1200Bicycles = 1 Full Load to Customer 1 x week, 3,125 units Cost Quality Rating .80 Delivery Rating .90 Lead Time (weeks) 2 .60 .80 3 5 Shuttle Suppliers Supplier A Supplier B Supplier C Supplier D Supplier E Supplier F Supplier G Supplier H Location Components Supplied Seattle, Wash Sprockets Dallas, TX Frames Joplin MS Wheels Milwaukee, WI Handle Bars Dallas, TX Handle Bars Joplin MS Chains Milwaukee, WI Frames Seattle, Wash Wheels .95 .70 .75 .90 $100 $150 $75 $500 $450 $300 $400 $200 WN .85 .90 6 .80 .95 .90 .80 .95 .85 8 10 Requirement 1: Develop your plant's operations and supply chain strategy: Clearly identify the following: Mission statement Identify you focus points Requirement 2: Illustrate your plants manufacturing process, layout, and customization point/s Requirement 3: Provide your plants quality strategy and definition Provide one process example where you will utilize upper and lower control limits: (hint variable data) Requirement 4: Describe your plants capacity strategy - provide graphs Determine the number of operators and shifts needed to assemble your product What is your maximum capacity? Requirement 5 What is your total cost to deliver your product to your customers? Describe your logistics strategy and why? What is your annual delivery cost? CEO questions: 1) If the demand plan drop by 15%, how does this effect your direct labor, in the number of people and cost to the company? 2) What is your assembly line bottle neck? I ONLY NEED REQUIREMENT 4 AND 5 BMGT 1331 Team Project: Assignment: Your CEO/Professor has just been awardeda major contract for your company. He has directed your plant to develop a production and operations strategy to meet the new customer contract. Your objective is to produce a 5 to 8 page paper that will detail your plant's ability to build these new orders. Bicycles Annual Volume Plant Location Customer Location 150,000 units Houston, TX Orlando FL Operator Cost Monthly Demand Logistics: Air 1 day @ $1500/load, Truck 3 days @ $500/load, train 7 days @ $250/load Delivery Schedule $20/hr 12,500 units 1200Bicycles = 1 Full Load to Customer 1 x week, 3,125 units Cost Quality Rating .80 Delivery Rating .90 Lead Time (weeks) 2 .60 .80 3 5 Shuttle Suppliers Supplier A Supplier B Supplier C Supplier D Supplier E Supplier F Supplier G Supplier H Location Components Supplied Seattle, Wash Sprockets Dallas, TX Frames Joplin MS Wheels Milwaukee, WI Handle Bars Dallas, TX Handle Bars Joplin MS Chains Milwaukee, WI Frames Seattle, Wash Wheels .95 .70 .75 .90 $100 $150 $75 $500 $450 $300 $400 $200 WN .85 .90 6 .80 .95 .90 .80 .95 .85 8 10 Requirement 1: Develop your plant's operations and supply chain strategy: Clearly identify the following: Mission statement Identify you focus points Requirement 2: Illustrate your plants manufacturing process, layout, and customization point/s Requirement 3: Provide your plants quality strategy and definition Provide one process example where you will utilize upper and lower control limits: (hint variable data) Requirement 4: Describe your plants capacity strategy - provide graphs Determine the number of operators and shifts needed to assemble your product What is your maximum capacity? Requirement 5 What is your total cost to deliver your product to your customers? Describe your logistics strategy and why? What is your annual delivery cost? CEO questions: 1) If the demand plan drop by 15%, how does this effect your direct labor, in the number of people and cost to the company? 2) What is your assembly line bottle neckStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts