Question: Learning Activity: Ensuring Quality in the Supply Chain Background: When you put multiple machines together in a production line, even small errors in each machine

Learning Activity: Ensuring Quality in the Supply Chain

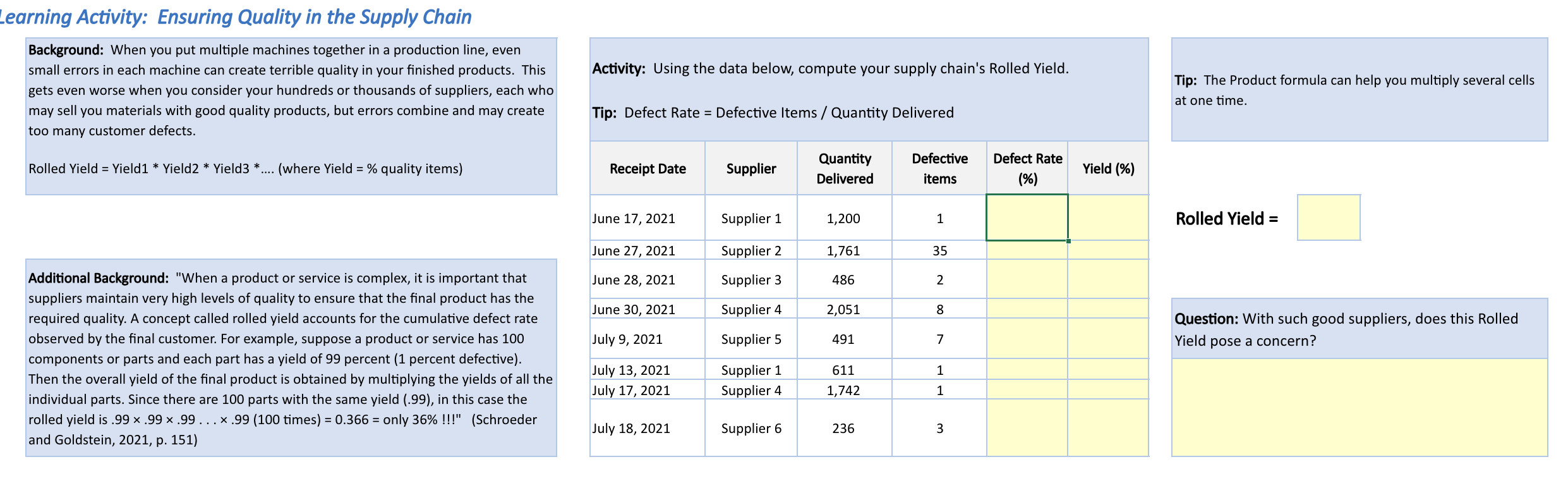

Background: When you put multiple machines together in a production line, even

small errors in each machine can create terrible quality in your finished products. This

gets even worse when you consider your hundreds or thousands of suppliers, each who

may sell you materials with good quality products, but errors combine and may create

too many customer defects.

Rolled Yield Yield Yield Yieldwhere Yield quality items

Additional Background: "When a product or service is complex, it is important that

suppliers maintain very high levels of quality to ensure that the final product has the

required quality. A concept called rolled yield accounts for the cumulative defect rate

observed by the final customer. For example, suppose a product or service has

components or parts and each part has a yield of percent percent defective

Then the overall yield of the final product is obtained by multiplying the yields of all the

individual parts. Since there are parts with the same yield in this case the

rolled yield is dots times only Schroeder

and Goldstein, p

Activity: Using the data below, compute your supply chain's Rolled Yield.

Tip: Defect Rate Defective Items Quantity Delivered

Tip: The Product formula can help you multiply several cells

at one time.

Rolled Yield

Question: With such good suppliers, does this Rolled

Yield pose a concern?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock