Question: Make a PLC Ladder Diagram Program to Implement an Automatic Car-Wash Process . Use Mitsubishi I/O addressing . Provide I/O List Sample Ladder Diagram using

Make a PLC Ladder Diagram Program to Implement an Automatic Car-Wash Process. Use Mitsubishi I/O addressing. Provide I/O List

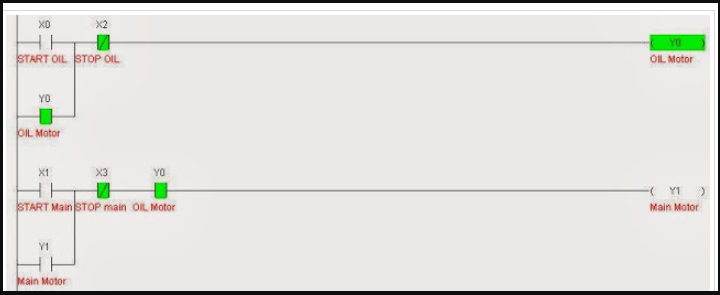

Sample Ladder Diagram using Mitsubishi Addressing.

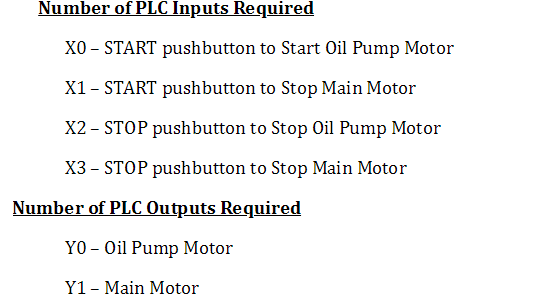

Sample I/O List.

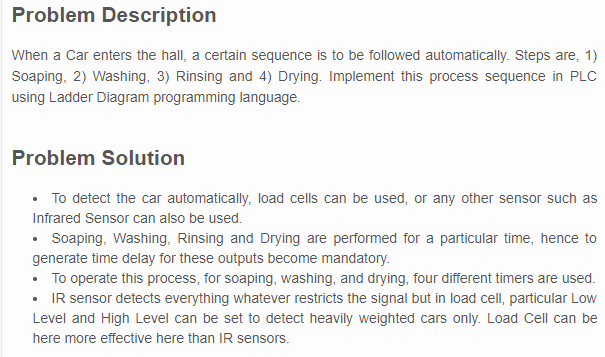

Problem Description When a Car enters the hall, a certain sequence is to be followed automatically Steps are, 1) Soaping, 2) Washing, 3) Rinsing and 4) Drying. Implement this process sequence in PLC using Ladder Diagram programming language Problem Solution To detect the car automatically, load cells can be used, or any other sensor such as Infrared Sensor can also be used. Soaping, Washing, Rinsing and Drying are performed for a particular time, hence to generate time delay for these outputs become mandatory To operate this process, for soaping, washing, and drying, four different timers are used. IR sensor detects everything whatever restricts the signal but in load cell, particular Low Level and High Level can be set to detect heavily weighted cars only. Load Cell can be here more effective here than IR sensors

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts