Question: need help finding buffer size, throughput rate, total time, and wgat is the total production time for 100 pieces In this assignment, we will practice

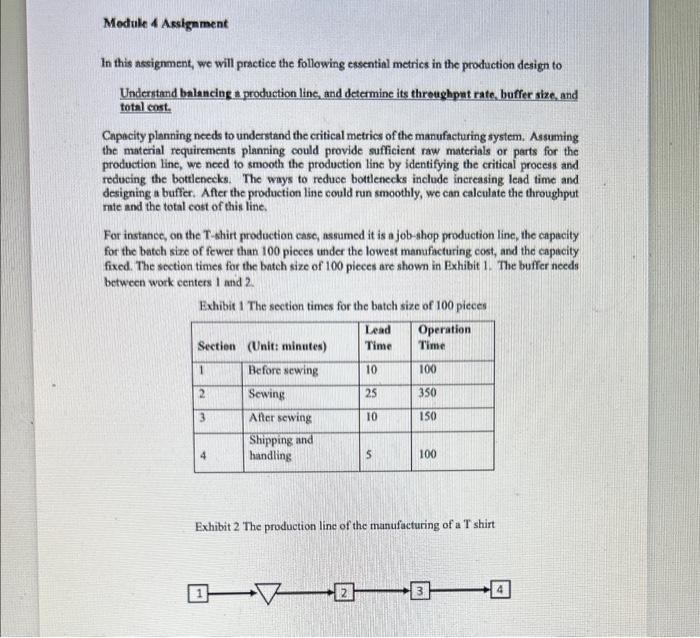

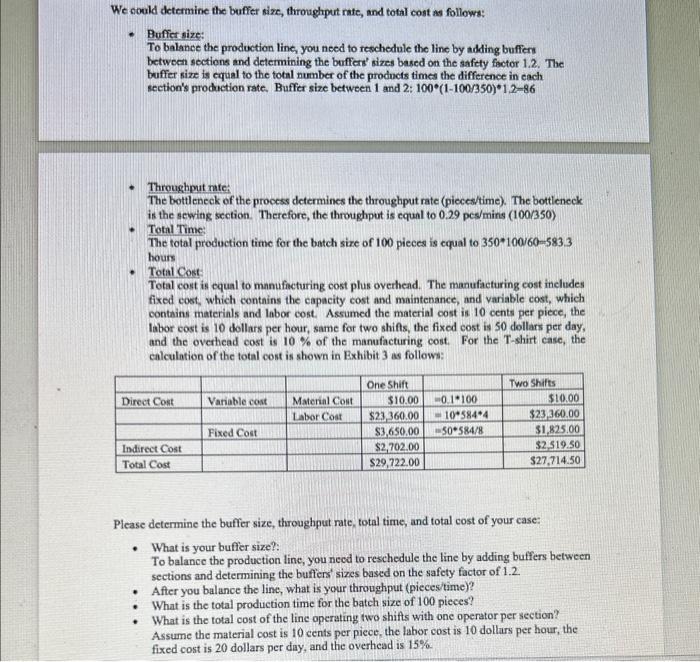

In this assignment, we will practice the following essential metrics in the production design to Understand balancine a production line, and determine its throughpat rate, buffer size, and total cost. Capacity planning needs to understand the critical metrics of the manufacturing system. Assuming the material requirements planning could provide sufficient raw materials or parts for the production line, we need to smooth the production line by identifying the critical process and roducing the bottlenecks. The wiys to reduce bottlenecks include increasing lead time and designing a buffer. After the production line could run smoothly, we can calculate the throughput mite and the total cost of this line. For instance, on the T-shirt production casc, assumed it is a job-shop production line, the capacity for the batch sixe of fewer than 100 pieces under the lowest manufacturing cost, and the capicity fixed. The section times for the bateh size of 100 picces are shown in Exhibit 1 . The buffer needs between work centers 1 and 2 Exhibit 1 The section times for the bateh size of 100 pieces Exhibit 2 The production line of the manufacturing of a T shirt We nould determine the buffer sixe, throughput rate, and total cost as follows: - Buffer size: To balanee the production line, you need to reschedule the line by adding buffers between sections and determining the buffers' sizes based on the safety factor 1.2. The buffer size is equal to the total number of the prodnets times the difference in each section's prodection rate. Buffer size between 1 and 2:100(1100/350)1,2=86 - Throughput nate The bottleneck of the process determines the throughput rate (piocesitime). The bottleneck is the sewing section. Therefore, the throughput is equal to 0.29pes/mins(100/350) - Total Time: The total production time for the batch size of 100 pieces is cqual to 350%100/60=583.3 hours - Total Cost. Total cost is equal to manuficturing cost plus overhead. The manufacturing cost includes fixed cost, which contains the capacity cost and maintenance, and variable cost, which contains materials and labor cost. Assumed the material cost is 10 cents per piece, the labor cost is 10 dollars per hour, same for two shifts, the fixed cost is 50 dollars per day, and the overhead cost is 10% of the manufacturing cost. For the T-shirt case, the calculation of the total cost is shown in Exhibit 3 as follows: Please determine the buffer size, throughput rate, total time, and total cost of your case: - What is your buffer size?: To balance the production line, you neod to reschedule the line by adding buffers between sections and determining the buffers' sizes based on the safety factor of 1.2. - After you balance the line, what is your throughput (pieces/time)? - What is the total production time for the batch size of 100 pieces? - What is the total cost of the line operating two shifts with one operator per section? Assume the material cost is 10 cents per piece, the labor cost is 10 dollars per hour, the fixed cost is 20 dollars per day, and the overhead is 15%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts