Question: Objective: In this homework you will determine how to design an assembly process, with the result being a balanced line that meets a specified production

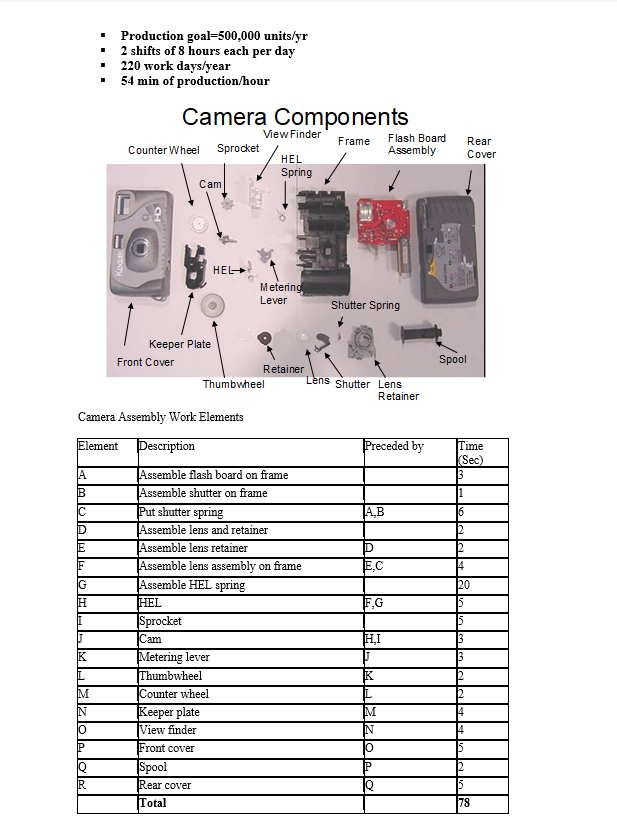

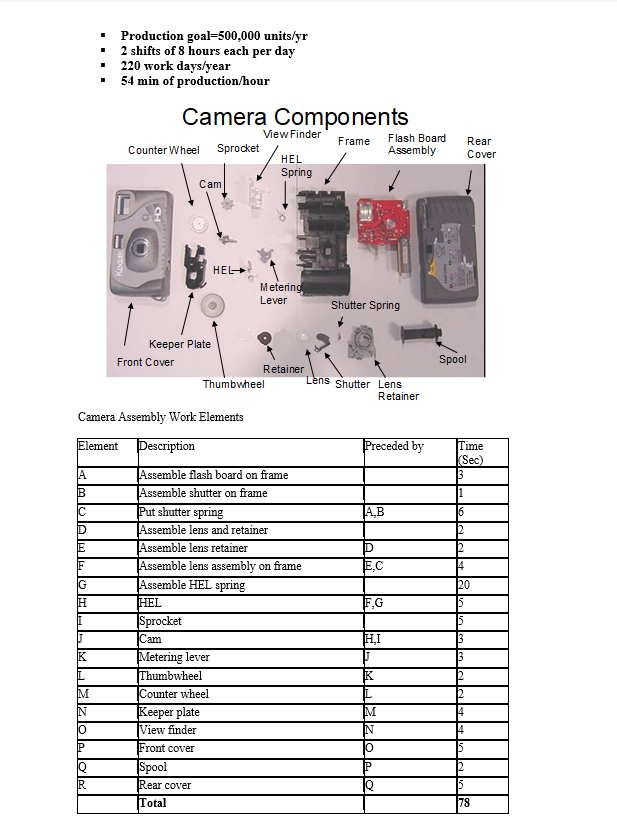

Objective: In this homework you will determine how to design an assembly process, with the result being a balanced line that meets a specified production requirement. This homework will provide you with an opportunity to link some earlier material in the course with topics we have just studied, including line balancing and precedence relationships. Discussion: The manufacturing of high volume products is frequently characterized by the use of fabricating and assembly production lines. The first steps in designing an assembly conveyor system are to create elemental descriptions, determine the time required to perform each element, and define the precedence relationships among the elements that constitute the assembly task. A few reminders about precedence relationships and line balancing: Define work elements about as small as they can be and still be done efficiently. Some work elements must precede others - this is the concept of precedence relationships. When setting up an assembly line with a need to respect precedence relationships and meet a production quota, you need to know the standard time of each work element. Steps to line balancing while respecting precedence relationships: o Create a precedence matrix (PM) o Use PM to determine positional weight of each work element o In descending order. list elements based on positional weight o Assign work elements to workstations, starting with the element with the greatest positional weight and working down to the one with the least weight. o Rule (note that this is modified from what appeared in the course notes): Fill up each workstation with the work element with the next largest positional time until the unassigned time is minimized; you can return to fill up unassigned time of previous workstations so long you do not violate the precedence (do not try to assign a work element to a workstation that precedes that work element's immediate predecessor, for example). What you must determine: Determine the precedence order of the work elements and draw precedence chart. Determine the required cycle time (line speed). Create the precedence matrix and determine the positional weights of the work elements. Work through the precedence relationships to design a balanced assembly line that respects those relationships and meets the production requirement. Show the arrangement of the workstations, which elements are performed at each workstation, total time for each workstation and indicate the unassigned times for each workstation. Production goal=500,000 units/yr 2 shifts of 8 hours each per day 220 work days/year 54 min of production/hour Rear Cover Camera Components View Finder Frame Flash Board Counter Wheel Sprocket Assembly Spring Cam D HEL HEL Metering Lever Shutter Spring Spool Keeper Plate Front Cover Retainer Thumbwheel Lens Shutter Lens Retainer Camera Assembly Work Elements Element Description Preceded by Time (Sec) A B IC A.B 6 IE F E.C 20 G H F G T Assemble flash board on frame Assemble shutter on frame Put shutter spring Assemble lens and retainer Assemble lens retainer Assemble lens assembly on frame Assemble HEL spring HEL Sprocket Cam Metering lever Thumbwheel Counter wheel Keeper plate View finder Front cover Spool Rear cover Total HI K M N M N ola P IQ R 5 78 Objective: In this homework you will determine how to design an assembly process, with the result being a balanced line that meets a specified production requirement. This homework will provide you with an opportunity to link some earlier material in the course with topics we have just studied, including line balancing and precedence relationships. Discussion: The manufacturing of high volume products is frequently characterized by the use of fabricating and assembly production lines. The first steps in designing an assembly conveyor system are to create elemental descriptions, determine the time required to perform each element, and define the precedence relationships among the elements that constitute the assembly task. A few reminders about precedence relationships and line balancing: Define work elements about as small as they can be and still be done efficiently. Some work elements must precede others - this is the concept of precedence relationships. When setting up an assembly line with a need to respect precedence relationships and meet a production quota, you need to know the standard time of each work element. Steps to line balancing while respecting precedence relationships: o Create a precedence matrix (PM) o Use PM to determine positional weight of each work element o In descending order. list elements based on positional weight o Assign work elements to workstations, starting with the element with the greatest positional weight and working down to the one with the least weight. o Rule (note that this is modified from what appeared in the course notes): Fill up each workstation with the work element with the next largest positional time until the unassigned time is minimized; you can return to fill up unassigned time of previous workstations so long you do not violate the precedence (do not try to assign a work element to a workstation that precedes that work element's immediate predecessor, for example). What you must determine: Determine the precedence order of the work elements and draw precedence chart. Determine the required cycle time (line speed). Create the precedence matrix and determine the positional weights of the work elements. Work through the precedence relationships to design a balanced assembly line that respects those relationships and meets the production requirement. Show the arrangement of the workstations, which elements are performed at each workstation, total time for each workstation and indicate the unassigned times for each workstation. Production goal=500,000 units/yr 2 shifts of 8 hours each per day 220 work days/year 54 min of production/hour Rear Cover Camera Components View Finder Frame Flash Board Counter Wheel Sprocket Assembly Spring Cam D HEL HEL Metering Lever Shutter Spring Spool Keeper Plate Front Cover Retainer Thumbwheel Lens Shutter Lens Retainer Camera Assembly Work Elements Element Description Preceded by Time (Sec) A B IC A.B 6 IE F E.C 20 G H F G T Assemble flash board on frame Assemble shutter on frame Put shutter spring Assemble lens and retainer Assemble lens retainer Assemble lens assembly on frame Assemble HEL spring HEL Sprocket Cam Metering lever Thumbwheel Counter wheel Keeper plate View finder Front cover Spool Rear cover Total HI K M N M N ola P IQ R 5 78