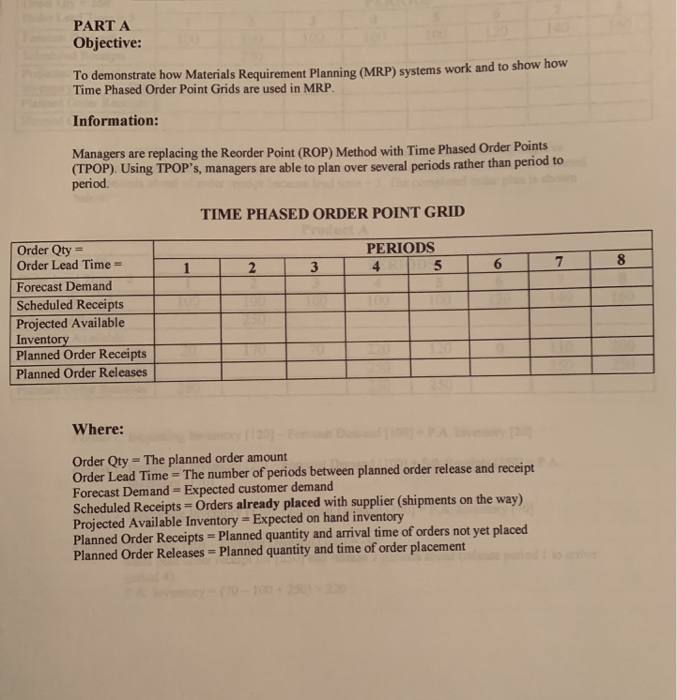

Question: PART A Objective: To demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP.

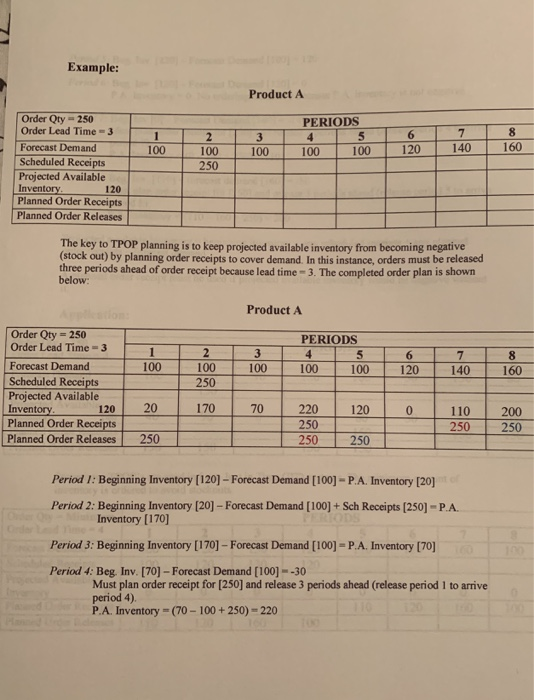

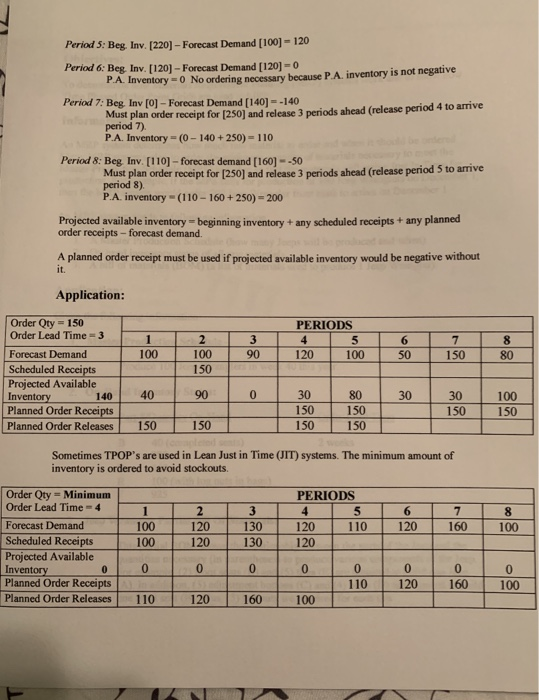

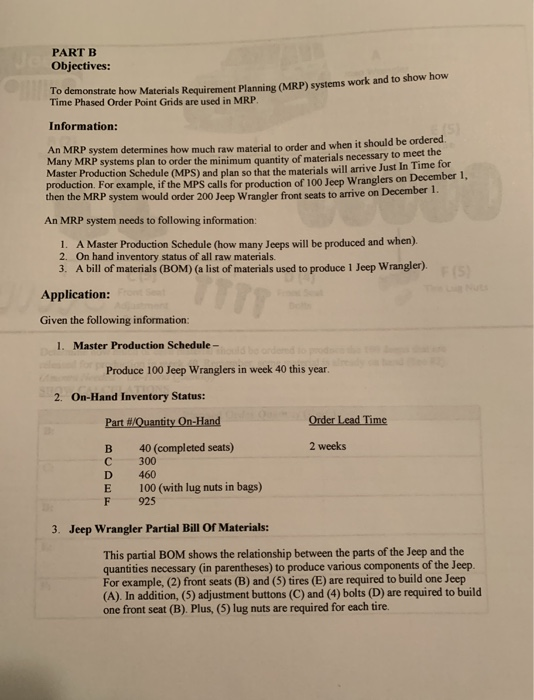

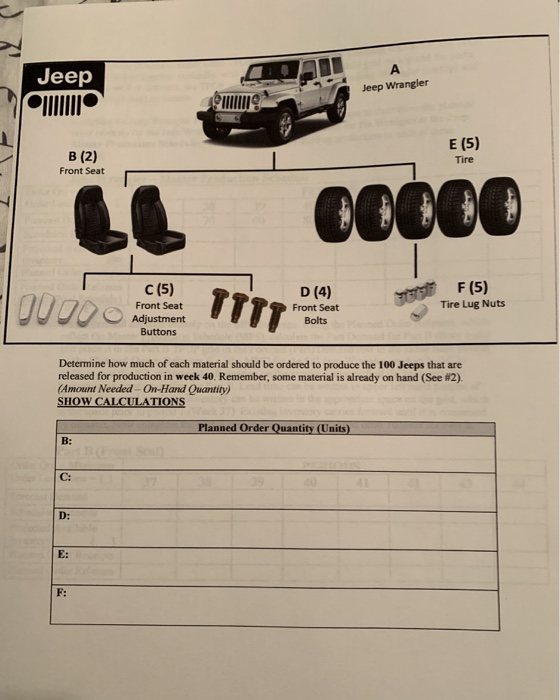

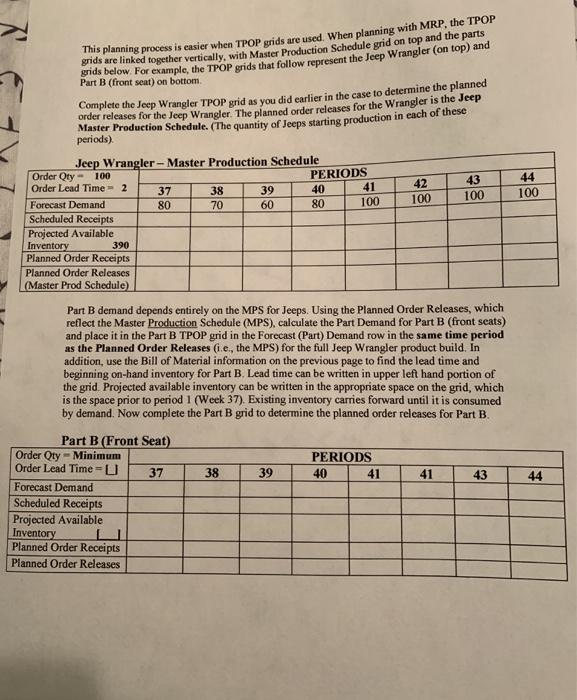

PART A Objective: To demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP. Information: Managers are replacing the Reorder Point (ROP) Method with Time Phased Order Points (TPOP). Using TPOP's, managers are able to plan over several periods rather than period to period. TIME PHASED ORDER POINT GRID PERIODS 45 2 Order Qty = Order Lead Time Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases Where: Order Qty - The planned order amount Order Lead Time The number of periods between planned order release and receipt Forecast Demand - Expected customer demand Scheduled Receipts Orders already placed with supplier (shipments on the way) Projected Available Inventory Expected on hand inventory Planned Order Receipts = Planned quantity and arrival time of orders not yet placed Planned Order Releases = Planned quantity and time of order placement Example: Product A 1 3 100 PERIODS 4 5 100 100 2 100 250 6 120 7 140 8 160 100 Order Qty 250 Order Lead Time=3 Forecast Demand Scheduled Receipts Projected Available Inventory 120 Planned Order Receipts Planned Order Releases The key to TPOP planning is to keep projected available inventory from becoming negative (stock out) by planning order receipts to cover demand. In this instance, orders must be released three periods ahead of order receipt because lead time - 3. The completed order plan is shown below: Product A 2 PERIODS 4 5 100 100 100 100 100 6 120 7 140 8 160 Order Qty = 250 Order Lead Time - 3 Forecast Demand Scheduled Receipts Projected Available Inventory. 120 Planned Order Receipts Planned Order Releases 250 20 170 0 110200 250 250 250 250 250 250 Period 7: Beginning Inventory [120] - Forecast Demand [100] - P.A. Inventory [20] Period 2: Beginning Inventory [20] - Forecast Demand [100] + Sch Receipts [250] - P.A. Inventory (170) Period 3: Beginning Inventory [170] - Forecast Demand [100] - P.A. Inventory [70] Period 4: Beg. Inv. [70] - Forecast Demand [100] --30 Must plan order receipt for (250) and release 3 periods ahead (release period I to arrive period 4). P.A. Inventory =(70 - 100 + 250) = 220 Period 5: Beg Inv. [220] - Forecast Demand [100] - 120 Period 6: Beg. Inv. [120] - Forecast Demand [120] =0 PA Inventory - O No ordering necessary because P.A. inventory is not negative Period 7: Beg. Inv [O] - Forecast Demand [140] -140 Must plan order receipt for [250] and release 3 periods ahead (release period 4 to arrive period 7) P.A. Inventory =(0 - 140+250) = 110 Period 8: Beg Inv. (110) - forecast demand [160] --50 Must plan order receipt for [250] and release 3 periods ahead (release period 5 to arrive period 8) P.A. inventory -(110 - 160+250) = 200 Projected available inventory beginning inventory + any scheduled receipts + any planned order receipts - forecast demand. A planned order receipt must be used if projected available inventory would be negative without Application: 6 PERIODS 4 5 120 100 2 100 150 3 90 100 150 80 Order Qty - 150 Order Lead Time - 3 Forecast Demand Scheduled Receipts Projected Available Inventory 140 Planned Order Receipts Planned Order Releases 40 900 30803030100 150 150 150 150 150 150 150 150 Sometimes TPOP's are used in Lean Justin Time (JIT) systems. The minimum amount of inventory is ordered to avoid stockouts. PERIODS 5 6 7 8 1 100 100 2 120 120 3 130 130 110 Order Qty - Minimum Order Lead Time - 4 Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases 120 160 100 120 120 0 0 0 0 0 110 0 120 0 160 100 110 120 160 100 PART B Objectives: demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP Information: An MRP system determines how much raw material to order and when it should be ordered Many MRP systems plan to order the minimum quantity of materials necessary to meet the Master Production Schedule (MPS) and plan so that the materials will arrive Just In Time for production. For example, if the MPS calls for production of 100 Jeep Wranglers on December 1, then the MRP system would order 200 Jeep Wrangler front seats to arrive on December 1. An MRP system needs to following information: 1. A Master Production Schedule (how many Jeeps will be produced and when). 2. On hand inventory status of all raw materials. 3. A bill of materials (BOM) (a list of materials used to produce 1 Jeep Wrangler). Application: Given the following information: Master Production Schedule - Produce 100 Jeep Wranglers in week 40 this year. 2. On-Hand Inventory Status: Part #/Quantity On-Hand Order Lead Time 2 weeks 40 (completed seats) 300 B C D E F 460 100 (with lug nuts in bags) 925 3. Jeep Wrangler Partial Bill Of Materials: This partial BOM shows the relationship between the parts of the Jeep and the quantities necessary (in parentheses) to produce various components of the Jeep. For example, (2) front seats (B) and (5) tires (E) are required to build one Jeep (A). In addition, (5) adjustment buttons (C) and (4) bolts (D) are required to build one front seat (B). Plus, (5) lug nuts are required for each tire. Jeep Jeep Wrangler OMS ma E (5) B (2) Front Seat Tire 00006 doente - F(5) Floucester TTT C(5) Front Seat Adjustment Buttons D (4) Front Seat Bolts Tire Lug Nuts Determine how much of each material should be ordered to produce the 100 Jeeps that are released for production in week 40. Remember, some material is already on hand (See 82). (Amount Needed-On-Hand Quantity) SHOW CALCULATIONS Planned Order Quantity (Units) This planning process is easier w anning process is easier when TPOP grids are used. When planning with MRP, the TPOP linked together vertically, with Master Production Schedule grid on top and the parts srids below. For example, the TPOP grids that follow represent the Jeep Wrangler (on top) and Part B (front seat) on bottom Complete the Jeep Wrangler TPOP grid as you did earlier in the case to determine the planned order releases for the Jeep Wrangler. The planned order releases for the Wrangler is the secp Master Production Schedule. (The quantity of Jeeps starting production in caci periods) 42 100 100 43 100 100 Jeep Wrangler - Master Production Schedule Order Qty - 100 PERIODS Order Lead Time - 2 37 38 39 40 41 Forecast Demand 80 70 60 80 80 100 100 Scheduled Receipts Projected Available Inventory 390 Planned Order Receipts Planned Order Releases (Master Prod Schedule) Part B demand depends entirely on the MPS for Jeeps. Using the Planned Order Releases, which reflect the Master Production Schedule (MPS), calculate the Part Demand for Part B (front seats) and place it in the Part B TPOP grid in the Forecast (Part) Demand row in the same time period as the Planned Order Releases (ie., the MPS) for the full Jeep Wrangler product build. In addition, use the Bill of Material information on the previous page to find the lead time and beginning on-hand inventory for Part B. Lead time can be written in upper left hand portion of the grid. Projected available inventory can be written in the appropriate space on the grid, which is the space prior to period 1 (Week 37). Existing inventory carries forward until it is consumed by demand. Now complete the Part B grid to determine the planned order releases for Part B. 38 39 PERIODS 40 41 41 43 Part B (Front Seat) Order Oty - Minimum Order Lead Time - 0 3 7 Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases PART A Objective: To demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP. Information: Managers are replacing the Reorder Point (ROP) Method with Time Phased Order Points (TPOP). Using TPOP's, managers are able to plan over several periods rather than period to period. TIME PHASED ORDER POINT GRID PERIODS 45 2 Order Qty = Order Lead Time Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases Where: Order Qty - The planned order amount Order Lead Time The number of periods between planned order release and receipt Forecast Demand - Expected customer demand Scheduled Receipts Orders already placed with supplier (shipments on the way) Projected Available Inventory Expected on hand inventory Planned Order Receipts = Planned quantity and arrival time of orders not yet placed Planned Order Releases = Planned quantity and time of order placement Example: Product A 1 3 100 PERIODS 4 5 100 100 2 100 250 6 120 7 140 8 160 100 Order Qty 250 Order Lead Time=3 Forecast Demand Scheduled Receipts Projected Available Inventory 120 Planned Order Receipts Planned Order Releases The key to TPOP planning is to keep projected available inventory from becoming negative (stock out) by planning order receipts to cover demand. In this instance, orders must be released three periods ahead of order receipt because lead time - 3. The completed order plan is shown below: Product A 2 PERIODS 4 5 100 100 100 100 100 6 120 7 140 8 160 Order Qty = 250 Order Lead Time - 3 Forecast Demand Scheduled Receipts Projected Available Inventory. 120 Planned Order Receipts Planned Order Releases 250 20 170 0 110200 250 250 250 250 250 250 Period 7: Beginning Inventory [120] - Forecast Demand [100] - P.A. Inventory [20] Period 2: Beginning Inventory [20] - Forecast Demand [100] + Sch Receipts [250] - P.A. Inventory (170) Period 3: Beginning Inventory [170] - Forecast Demand [100] - P.A. Inventory [70] Period 4: Beg. Inv. [70] - Forecast Demand [100] --30 Must plan order receipt for (250) and release 3 periods ahead (release period I to arrive period 4). P.A. Inventory =(70 - 100 + 250) = 220 Period 5: Beg Inv. [220] - Forecast Demand [100] - 120 Period 6: Beg. Inv. [120] - Forecast Demand [120] =0 PA Inventory - O No ordering necessary because P.A. inventory is not negative Period 7: Beg. Inv [O] - Forecast Demand [140] -140 Must plan order receipt for [250] and release 3 periods ahead (release period 4 to arrive period 7) P.A. Inventory =(0 - 140+250) = 110 Period 8: Beg Inv. (110) - forecast demand [160] --50 Must plan order receipt for [250] and release 3 periods ahead (release period 5 to arrive period 8) P.A. inventory -(110 - 160+250) = 200 Projected available inventory beginning inventory + any scheduled receipts + any planned order receipts - forecast demand. A planned order receipt must be used if projected available inventory would be negative without Application: 6 PERIODS 4 5 120 100 2 100 150 3 90 100 150 80 Order Qty - 150 Order Lead Time - 3 Forecast Demand Scheduled Receipts Projected Available Inventory 140 Planned Order Receipts Planned Order Releases 40 900 30803030100 150 150 150 150 150 150 150 150 Sometimes TPOP's are used in Lean Justin Time (JIT) systems. The minimum amount of inventory is ordered to avoid stockouts. PERIODS 5 6 7 8 1 100 100 2 120 120 3 130 130 110 Order Qty - Minimum Order Lead Time - 4 Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases 120 160 100 120 120 0 0 0 0 0 110 0 120 0 160 100 110 120 160 100 PART B Objectives: demonstrate how Materials Requirement Planning (MRP) systems work and to show how Time Phased Order Point Grids are used in MRP Information: An MRP system determines how much raw material to order and when it should be ordered Many MRP systems plan to order the minimum quantity of materials necessary to meet the Master Production Schedule (MPS) and plan so that the materials will arrive Just In Time for production. For example, if the MPS calls for production of 100 Jeep Wranglers on December 1, then the MRP system would order 200 Jeep Wrangler front seats to arrive on December 1. An MRP system needs to following information: 1. A Master Production Schedule (how many Jeeps will be produced and when). 2. On hand inventory status of all raw materials. 3. A bill of materials (BOM) (a list of materials used to produce 1 Jeep Wrangler). Application: Given the following information: Master Production Schedule - Produce 100 Jeep Wranglers in week 40 this year. 2. On-Hand Inventory Status: Part #/Quantity On-Hand Order Lead Time 2 weeks 40 (completed seats) 300 B C D E F 460 100 (with lug nuts in bags) 925 3. Jeep Wrangler Partial Bill Of Materials: This partial BOM shows the relationship between the parts of the Jeep and the quantities necessary (in parentheses) to produce various components of the Jeep. For example, (2) front seats (B) and (5) tires (E) are required to build one Jeep (A). In addition, (5) adjustment buttons (C) and (4) bolts (D) are required to build one front seat (B). Plus, (5) lug nuts are required for each tire. Jeep Jeep Wrangler OMS ma E (5) B (2) Front Seat Tire 00006 doente - F(5) Floucester TTT C(5) Front Seat Adjustment Buttons D (4) Front Seat Bolts Tire Lug Nuts Determine how much of each material should be ordered to produce the 100 Jeeps that are released for production in week 40. Remember, some material is already on hand (See 82). (Amount Needed-On-Hand Quantity) SHOW CALCULATIONS Planned Order Quantity (Units) This planning process is easier w anning process is easier when TPOP grids are used. When planning with MRP, the TPOP linked together vertically, with Master Production Schedule grid on top and the parts srids below. For example, the TPOP grids that follow represent the Jeep Wrangler (on top) and Part B (front seat) on bottom Complete the Jeep Wrangler TPOP grid as you did earlier in the case to determine the planned order releases for the Jeep Wrangler. The planned order releases for the Wrangler is the secp Master Production Schedule. (The quantity of Jeeps starting production in caci periods) 42 100 100 43 100 100 Jeep Wrangler - Master Production Schedule Order Qty - 100 PERIODS Order Lead Time - 2 37 38 39 40 41 Forecast Demand 80 70 60 80 80 100 100 Scheduled Receipts Projected Available Inventory 390 Planned Order Receipts Planned Order Releases (Master Prod Schedule) Part B demand depends entirely on the MPS for Jeeps. Using the Planned Order Releases, which reflect the Master Production Schedule (MPS), calculate the Part Demand for Part B (front seats) and place it in the Part B TPOP grid in the Forecast (Part) Demand row in the same time period as the Planned Order Releases (ie., the MPS) for the full Jeep Wrangler product build. In addition, use the Bill of Material information on the previous page to find the lead time and beginning on-hand inventory for Part B. Lead time can be written in upper left hand portion of the grid. Projected available inventory can be written in the appropriate space on the grid, which is the space prior to period 1 (Week 37). Existing inventory carries forward until it is consumed by demand. Now complete the Part B grid to determine the planned order releases for Part B. 38 39 PERIODS 40 41 41 43 Part B (Front Seat) Order Oty - Minimum Order Lead Time - 0 3 7 Forecast Demand Scheduled Receipts Projected Available Inventory Planned Order Receipts Planned Order Releases