Question: please answer the following questions as an operation manager for the company This assigned project aims to enable a student analyzes the given quantitative information,

please answer the following questions as an operation manager for the company

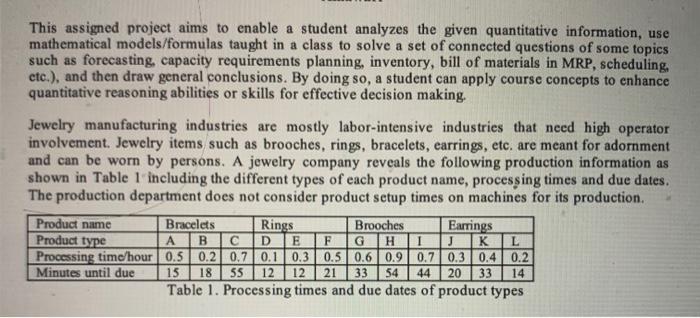

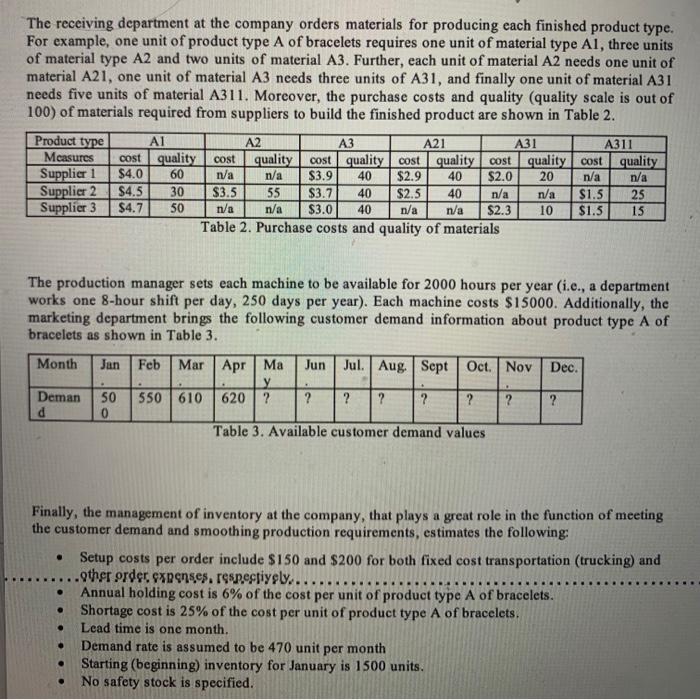

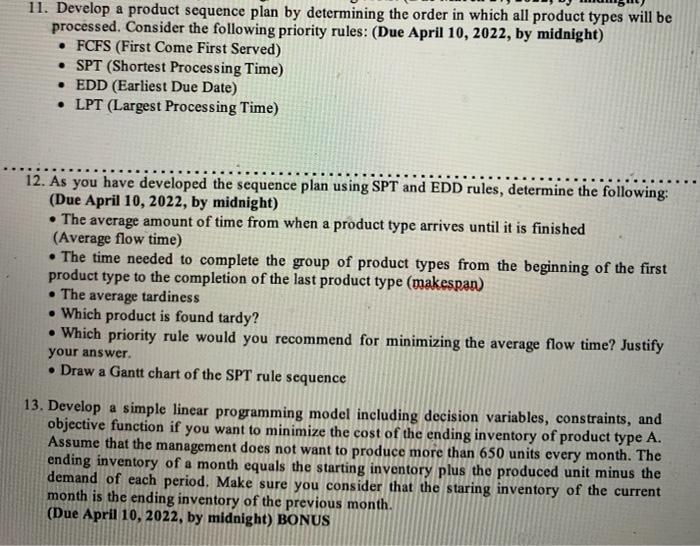

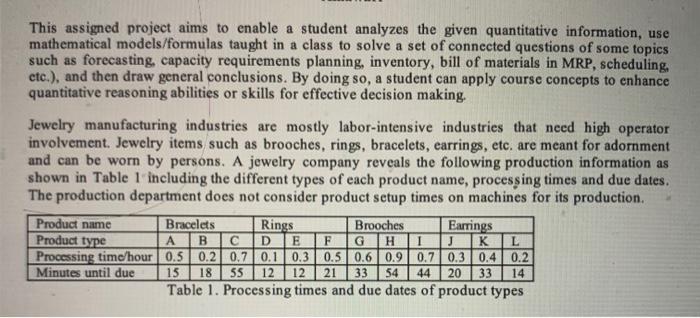

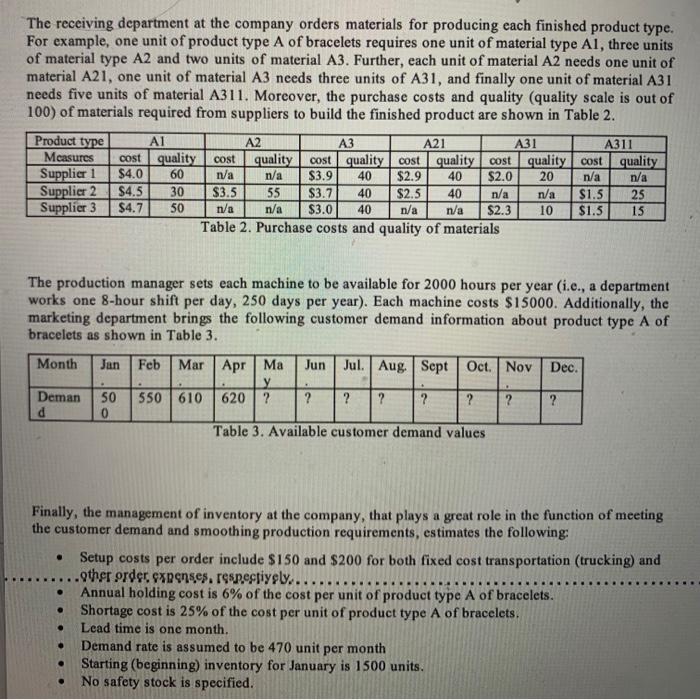

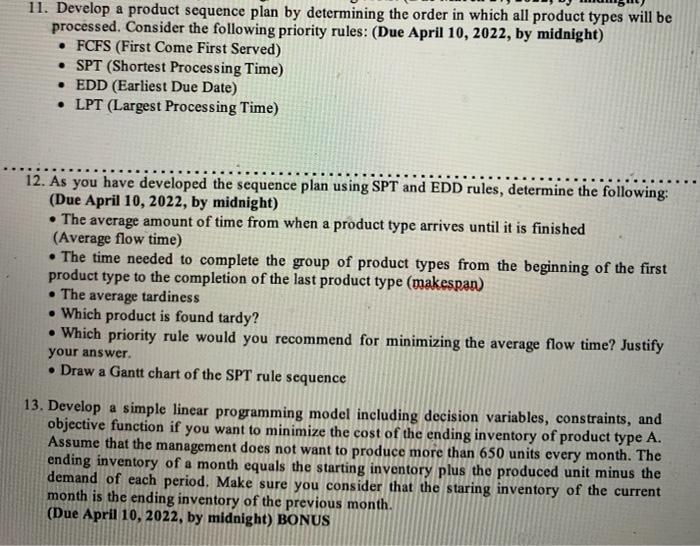

This assigned project aims to enable a student analyzes the given quantitative information, use mathematical models/formulas taught in a class to solve a set of connected questions of some topics such as forecasting, capacity requirements planning, inventory, bill of materials in MRP, scheduling, etc.), and then draw general conclusions. By doing so, a student can apply course concepts to enhance quantitative reasoning abilities or skills for effective decision making. Jewelry manufacturing industries are mostly labor-intensive industries that need high operator involvement. Jewelry items such as brooches, rings, bracelets, earrings, etc. are meant for adornment and can be worn by persons. A jewelry company reveals the following production information as shown in Table 1 including the different types of each product name, processing times and due dates. The production department does not consider product setup times on machines for its production. Product name Bracelets Rings Brooches Earrings Product type H K Processing time/hour 0.5 0.2 0.7 0.1 0.3 0.5 0.6 0.9 0.7 0.3 0.4 0.2 Minutes until due 55 12 33 54 44 20 33 14 Table 1. Processing times and due dates of product types A B D E F G 1 J L 15 18 12 21 The receiving department at the company orders materials for producing each finished product type. For example, one unit of product type A of bracelets requires one unit of material type Al, three units of material type A2 and two units of material A3. Further, each unit of material A2 needs one unit of material A21, one unit of material A3 needs three units of A31, and finally one unit of material A31 needs five units of material A311. Moreover, the purchase costs and quality (quality scale is out of 100) of materials required from suppliers to build the finished product are shown in Table 2. Product type A2 A3 A21 A31 A311 Measures cost quality cost quality cost quality cost quality cost quality cost quality Supplier 1 $4.0 60 wa n/a $3.9 40 $2.9 40 $2.0 n/a n/a Supplier 2 $4.5 30 $3.5 55 $3.7 40 $2.5 40 n/a n/a $1.5 25 Supplier 3 $4.7 50 n/a n/a $3.0 40 n/a n/a $2.3 10 $1.5 15 Table 2. Purchase costs and quality of materials 20 The production manager sets each machine to be available for 2000 hours per year (i.e., a department works one 8-hour shift per day, 250 days per year). Each machine costs $15000. Additionally, the marketing department brings the following customer demand information about product type A of bracelets as shown in Table 3. Month Jan Feb Mar Apr Ma Jun Jul. Aug. Sept Oct. Nov Dec. Deman d 550610 620? ? 50 0 ? ? ? ? 2 ? Table 3. Available customer demand values Finally, the management of inventory at the company, that plays a great role in the function of meeting the customer demand and smoothing production requirements, estimates the following: Setup costs per order include $150 and $200 for both fixed cost transportation (trucking) and ..other ordet expenses. resnestiysly....... Annual holding cost is 6% of the cost per unit of product type A of bracelets. Shortage cost is 25% of the cost per unit of product type A of bracelets. Lead time is one month. Demand rate is assumed to be 470 unit per month Starting (beginning) inventory for January is 1500 units. No safety stock is specified. . 11. Develop a product sequence plan by determining the order in which all product types will be processed. Consider the following priority rules: (Due April 10, 2022, by midnight) FCFS (First Come First Served) SPT (Shortest Processing Time) EDD (Earliest Due Date) LPT (Largest Processing Time) 12. As you have developed the sequence plan using SPT and EDD rules, determine the following: (Due April 10, 2022, by midnight) The average amount of time from when a product type arrives until it is finished (Average flow time) The time needed to complete the group of product types from the beginning of the first product type to the completion of the last product type (makespan) . The average tardiness Which product is found tardy? Which priority rule would you recommend for minimizing the average flow time? Justify your answer Draw a Gantt chart of the SPT rule sequence 13. Develop a simple linear programming model including decision variables, constraints, and objective function if you want to minimize the cost of the ending inventory of product type A. Assume that the management does not want to produce more than 650 units every month. The ending inventory of a month equals the starting inventory plus the produced unit minus the demand of each period. Make sure you consider that the staring inventory of the current month is the ending inventory of the previous month. (Due April 10, 2022, by midnight) BONUS

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock