Question: please answer this discussion question performance evaluation in minimum 300 words please answer this discussion I'm posting it for second time because no one answered

please answer this discussion question performance evaluation in minimum 300 words please answer this discussion I'm posting it for second time because no one answered this question previously and yes discussion question say that describes this discussion exactly like it says in a book page number 1051 so I'm also adding please pictures of page 1051 so please look at it and describe this discussion as like in page 1051

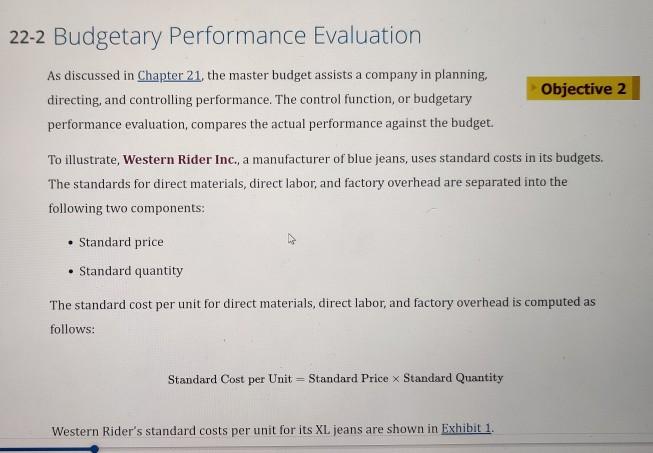

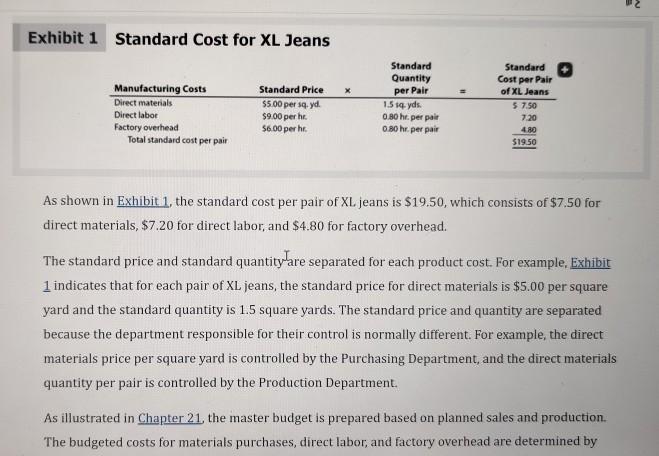

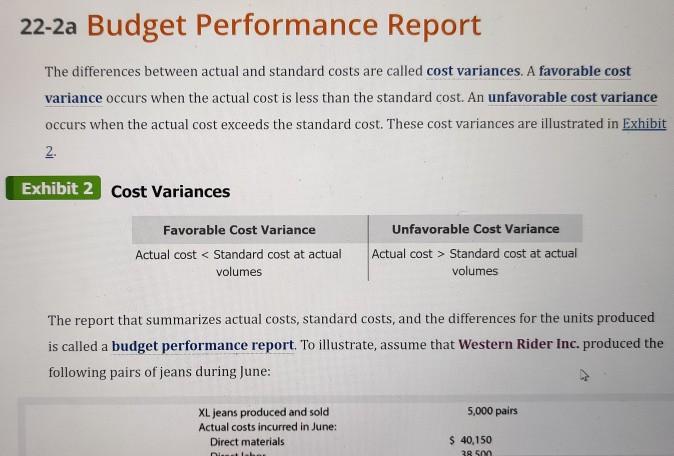

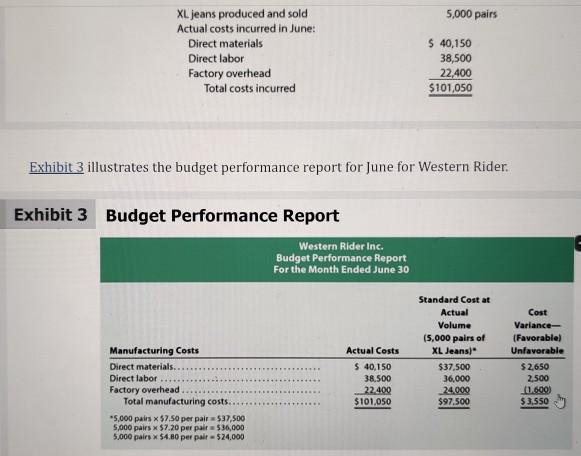

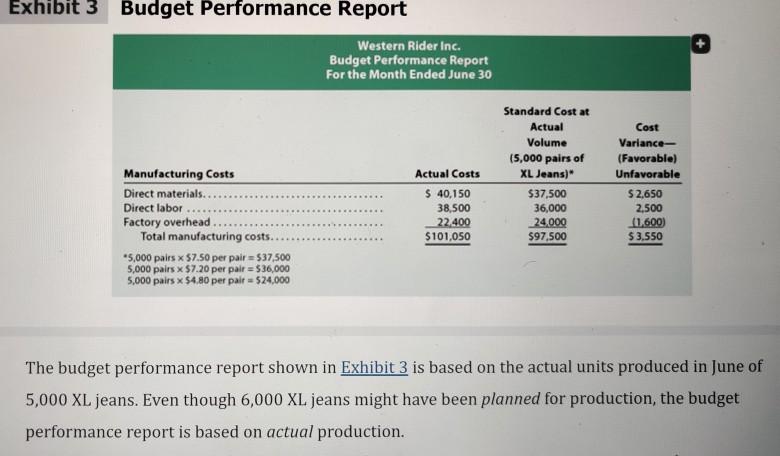

Chapter 22 Discussions Performance evaluation Why might firms use nonfinancial performance measures? What measures might a hospital use? Target? Chase Bank? City Colleges of Chicago? Select one of the above listed types of businesses and describe the inputs, activities, and outputs as described on page 1051 in your text. I expect you to respond to the posted question with a minimum 250 word response AND interact with your fellow students' thoughts and ideas by posting an additional 2 posts - adding your thoughts and insights to what they had to say. Saying "good job" or "I agree" would not count toward this grade. Please spread your interactions out throughout the week. I cannot grant full points if you post one reply after the other on a single day. 22-2 Budgetary Performance Evaluation As discussed in Chapter 21, the master budget assists a company in planning, directing, and controlling performance. The control function, or budgetary Objective 2 performance evaluation, compares the actual performance against the budget. To illustrate, Western Rider Inc., a manufacturer of blue jeans, uses standard costs in its budgets. The standards for direct materials, direct labor and factory overhead are separated into the following two components: Standard price Standard quantity The standard cost per unit for direct materials, direct labor, and factory overhead is computed as follows: Standard Cost per Unit - Standard Price x Standard Quantity Western Rider's standard costs per unit for its XL jeans are shown in Exhibit 1. 2 Exhibit 1 Standard Cost for XL Jeans Manufacturing Costs Direct materials Direct labor Factory overhead Total standard cost per pair Standard Price $5.00 per sq.yd. $9.00 per hr $6.00 per hr Standard Quantity per Pair 15 sq yds. 0.80 hr. per pair 0.80 hr. per pair Standard Cost per Pair of XL Jeans 5 7.50 7.20 480 $19.50 As shown in Exhibit 1, the standard cost per pair of XL jeans is $19.50, which consists of $7.50 for direct materials, $7.20 for direct labor, and $4.80 for factory overhead. The standard price and standard quantity are separated for each product cost. For example, Exhibit 1 indicates that for each pair of XL jeans, the standard price for direct materials is $5.00 per square yard and the standard quantity is 1.5 square yards. The standard price and quantity are separated because the department responsible for their control is normally different. For example, the direct materials price per square yard is controlled by the Purchasing Department, and the direct materials quantity per pair is controlled by the Production Department. As illustrated in Chapter 21. the master budget is prepared based on planned sales and production The budgeted costs for materials purchases, direct labor and factory overhead are determined by The standard price and standard quantity are separated for each product cost. For example, Exhibit 1 indicates that for each pair of XL jeans, the standard price for direct materials is $5.00 per square yard and the standard quantity is 1.5 square yards. The standard price and quantity are separated because the department responsible for their control is normally different. For example, the direct materials price per square yard is controlled by the Purchasing Department, and the direct materials quantity per pair is controlled by the Production Department. As illustrated in Chapter 21, the master budget is prepared based on planned sales and production. The budgeted costs for materials purchases, direct labor, and factory overhead are determined by multiplying their standard costs per unit by the planned level of production. Budgeted (standard) costs are then compared to actual costs during the year for control purposes. 22-2a Budget Performance Report The differences between actual and standard costs are called cost variances. A favorable cost variance occurs when the actual cost is less than the standard cost. An unfavorable cost variance occurs when the actual cost exceeds the standard cost. These cost variances are illustrated in Exhibit 2 Exhibit 2 Cost Variances Favorable Cost Variance Actual cost Standard cost at actual volumes The report that summarizes actual costs, standard costs, and the differences for the units produced is called a budget performance report. To illustrate, assume that Western Rider Inc. produced the following pairs of jeans during June: 5,000 pairs XL Jeans produced and sold Actual costs incurred in June: Direct materials $ 40,150 38 5 5,000 pairs XL jeans produced and sold Actual costs incurred in June: Direct materials Direct labor Factory overhead Total costs incurred $ 40,150 38,500 22,400 $101,050 Exhibit 3 illustrates the budget performance report for June for Western Rider. Exhibit 3 Budget Performance Report Western Rider Inc. Budget Performance Report For the Month Ended June 30 Manufacturing Costs Direct materials.. Direct labor Factory overhead Total manufacturing costs... *5,000 pairs x 57.50 per pair=537,500 5,000 pairs x $7.20 per palt=536,000 5,000 pairs x $4.0 per pair-524.000 Actual Costs $ 40,150 38.500 22.400 $101,050 Standard Cost at Actual Volume (5,000 pairs of XL Jeans}" $37.500 36,000 24.000 $97.500 Cost Variance (Favorable) Unfavorable $ 2.650 2,500 0.600) $3,550 Exhibit 3 Budget Performance Report Western Rider Inc. Budget Performance Report For the Month Ended June 30 Manufacturing Costs Direct materials.... Direct labor Factory overhead Total manufacturing costs. *5,000 pairs x 57.50 per pair = $37,500 5,000 pairs x 57.20 per pair = $36,000 5,000 pairs x $4,80 per pair -524.000 Actual Costs $ 40,150 38,500 22.400 $101,050 Standard Cost at Actual Volume (5,000 pairs of XL Jeans)" $37,500 36,000 24,000 $97.500 Cost Variance- (Favorable) Unfavorable $2.650 2,500 (1.600) $3.550 The budget performance report shown in Exhibit 3 is based on the actual units produced in June of 5,000 XL jeans. Even though 6,000 XL jeans might have been planned for production, the budget performance report is based on actual production. Chapter 22 Discussions Performance evaluation Why might firms use nonfinancial performance measures? What measures might a hospital use? Target? Chase Bank? City Colleges of Chicago? Select one of the above listed types of businesses and describe the inputs, activities, and outputs as described on page 1051 in your text. I expect you to respond to the posted question with a minimum 250 word response AND interact with your fellow students' thoughts and ideas by posting an additional 2 posts - adding your thoughts and insights to what they had to say. Saying "good job" or "I agree" would not count toward this grade. Please spread your interactions out throughout the week. I cannot grant full points if you post one reply after the other on a single day. 22-2 Budgetary Performance Evaluation As discussed in Chapter 21, the master budget assists a company in planning, directing, and controlling performance. The control function, or budgetary Objective 2 performance evaluation, compares the actual performance against the budget. To illustrate, Western Rider Inc., a manufacturer of blue jeans, uses standard costs in its budgets. The standards for direct materials, direct labor and factory overhead are separated into the following two components: Standard price Standard quantity The standard cost per unit for direct materials, direct labor, and factory overhead is computed as follows: Standard Cost per Unit - Standard Price x Standard Quantity Western Rider's standard costs per unit for its XL jeans are shown in Exhibit 1. 2 Exhibit 1 Standard Cost for XL Jeans Manufacturing Costs Direct materials Direct labor Factory overhead Total standard cost per pair Standard Price $5.00 per sq.yd. $9.00 per hr $6.00 per hr Standard Quantity per Pair 15 sq yds. 0.80 hr. per pair 0.80 hr. per pair Standard Cost per Pair of XL Jeans 5 7.50 7.20 480 $19.50 As shown in Exhibit 1, the standard cost per pair of XL jeans is $19.50, which consists of $7.50 for direct materials, $7.20 for direct labor, and $4.80 for factory overhead. The standard price and standard quantity are separated for each product cost. For example, Exhibit 1 indicates that for each pair of XL jeans, the standard price for direct materials is $5.00 per square yard and the standard quantity is 1.5 square yards. The standard price and quantity are separated because the department responsible for their control is normally different. For example, the direct materials price per square yard is controlled by the Purchasing Department, and the direct materials quantity per pair is controlled by the Production Department. As illustrated in Chapter 21. the master budget is prepared based on planned sales and production The budgeted costs for materials purchases, direct labor and factory overhead are determined by The standard price and standard quantity are separated for each product cost. For example, Exhibit 1 indicates that for each pair of XL jeans, the standard price for direct materials is $5.00 per square yard and the standard quantity is 1.5 square yards. The standard price and quantity are separated because the department responsible for their control is normally different. For example, the direct materials price per square yard is controlled by the Purchasing Department, and the direct materials quantity per pair is controlled by the Production Department. As illustrated in Chapter 21, the master budget is prepared based on planned sales and production. The budgeted costs for materials purchases, direct labor, and factory overhead are determined by multiplying their standard costs per unit by the planned level of production. Budgeted (standard) costs are then compared to actual costs during the year for control purposes. 22-2a Budget Performance Report The differences between actual and standard costs are called cost variances. A favorable cost variance occurs when the actual cost is less than the standard cost. An unfavorable cost variance occurs when the actual cost exceeds the standard cost. These cost variances are illustrated in Exhibit 2 Exhibit 2 Cost Variances Favorable Cost Variance Actual cost Standard cost at actual volumes The report that summarizes actual costs, standard costs, and the differences for the units produced is called a budget performance report. To illustrate, assume that Western Rider Inc. produced the following pairs of jeans during June: 5,000 pairs XL Jeans produced and sold Actual costs incurred in June: Direct materials $ 40,150 38 5 5,000 pairs XL jeans produced and sold Actual costs incurred in June: Direct materials Direct labor Factory overhead Total costs incurred $ 40,150 38,500 22,400 $101,050 Exhibit 3 illustrates the budget performance report for June for Western Rider. Exhibit 3 Budget Performance Report Western Rider Inc. Budget Performance Report For the Month Ended June 30 Manufacturing Costs Direct materials.. Direct labor Factory overhead Total manufacturing costs... *5,000 pairs x 57.50 per pair=537,500 5,000 pairs x $7.20 per palt=536,000 5,000 pairs x $4.0 per pair-524.000 Actual Costs $ 40,150 38.500 22.400 $101,050 Standard Cost at Actual Volume (5,000 pairs of XL Jeans}" $37.500 36,000 24.000 $97.500 Cost Variance (Favorable) Unfavorable $ 2.650 2,500 0.600) $3,550 Exhibit 3 Budget Performance Report Western Rider Inc. Budget Performance Report For the Month Ended June 30 Manufacturing Costs Direct materials.... Direct labor Factory overhead Total manufacturing costs. *5,000 pairs x 57.50 per pair = $37,500 5,000 pairs x 57.20 per pair = $36,000 5,000 pairs x $4,80 per pair -524.000 Actual Costs $ 40,150 38,500 22.400 $101,050 Standard Cost at Actual Volume (5,000 pairs of XL Jeans)" $37,500 36,000 24,000 $97.500 Cost Variance- (Favorable) Unfavorable $2.650 2,500 (1.600) $3.550 The budget performance report shown in Exhibit 3 is based on the actual units produced in June of 5,000 XL jeans. Even though 6,000 XL jeans might have been planned for production, the budget performance report is based on actual production

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts