Question: Please can you show the MATH work and DATA in excel to better explained the problem. Company Background MediCrystals Co . is a leading German

Please can you show the MATH work and DATA in excel to better explained the problem.

Company Background

MediCrystals Co. is a leading German pharmaceutical glass manufacturer offering a solution for the entire range of basic volume tubular glass parenteral packaging including ampoules, vials, cartridges and sterile pre-fillable syringes. They have multiple manufacturing plants in Europe, America and South-East Asia. MediCrystals has customers all over the world and supplies to over 120 countries.

Changing Landscape

MediCrystals Co. aims to provide pharma vials for Covid-19 vaccines to Payima Biotec (a global generic and specialty pharmaceutical and vaccine maker) and various other similar entities. They have signed agreements with major pharmaceutical firms to supply pharma glass products for the packaging of two billion doses of Covid-19 vaccines. The vaccine being developed currently can only be stored in glass vials. When the vaccine is approved, globally, manufacturers will struggle to source enough glass vials, syringes, and ampoules to bottle enough for the global immunization drive. MediCrystals manufactures over 8 billion pharma glass containers for drugs annually. There's a glass shortage currently due to the sudden increase in demand for such products. Many of the suppliers being small and localized, MediCrystals needs to be sure that none of their suppliers are facing business continuity challenges due to the pandemic. Manufacturers globally are facing financial and operational challenges; the demand is unpredictable, and there are concerns related to shortages and stockouts.

Current Supply Chain Operations

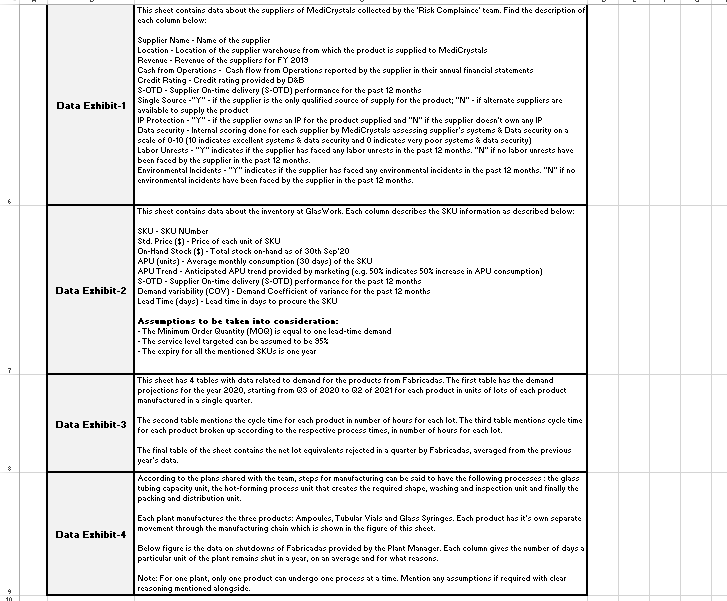

VP Operations at MediCrystals has hired your team to leverage expertise around three critical areas her team has identified. First, the Manager of Procurement and Sourcing team has heard from the CPO that some of the critical suppliers are facing operational challenges due to the pandemic. She thereby, intends to develop a high-level risk scoring methodology or rationale to score the suppliers and review mitigation activities currently in place. Based on the supplier data available, the Risk Compliance Manager has currently identified two risk domains - Finance, Regulatory. As part of the Regulatory risk domain, she intends to score each supplier based on the risk factors Labor unrests, and Environmental incidents. She wants your team to identify other risk domains and factors contributing to the risk domains based on the available supplier data. She wants your team to develop a comprehensive risk scoring methodology and identify suppliers that pose the most risk.

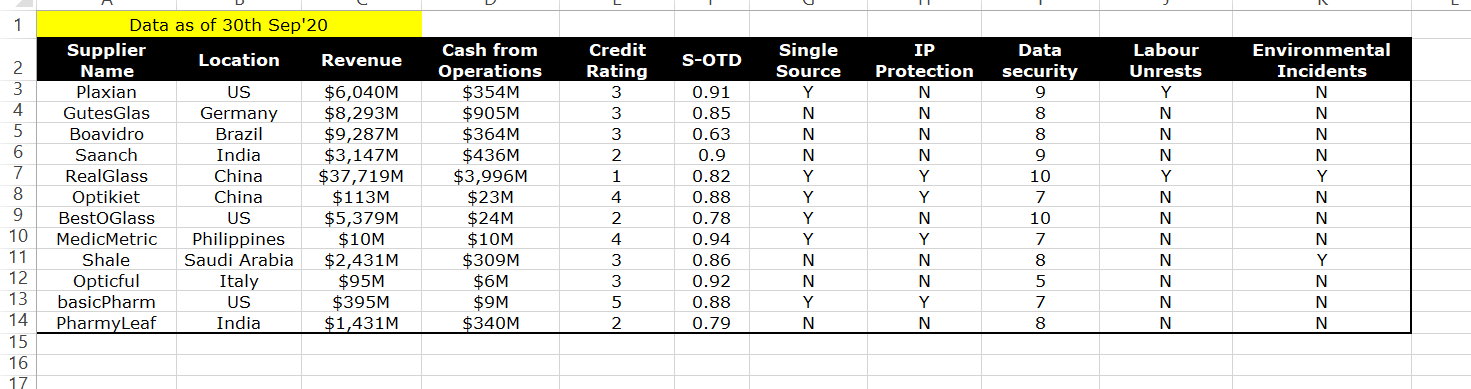

The marketing team has gathered insights regarding the anticipated demand trend for various SKUs based on their product families. Your team as part of this project, has been requested to estimate the change in the inventory position to understand the working capital impact in one of the most critical plants in Switzerland, GlasWork. Based on the marketing insights gathered, she also wants to understand the potential obsolete inventory that they currently have.

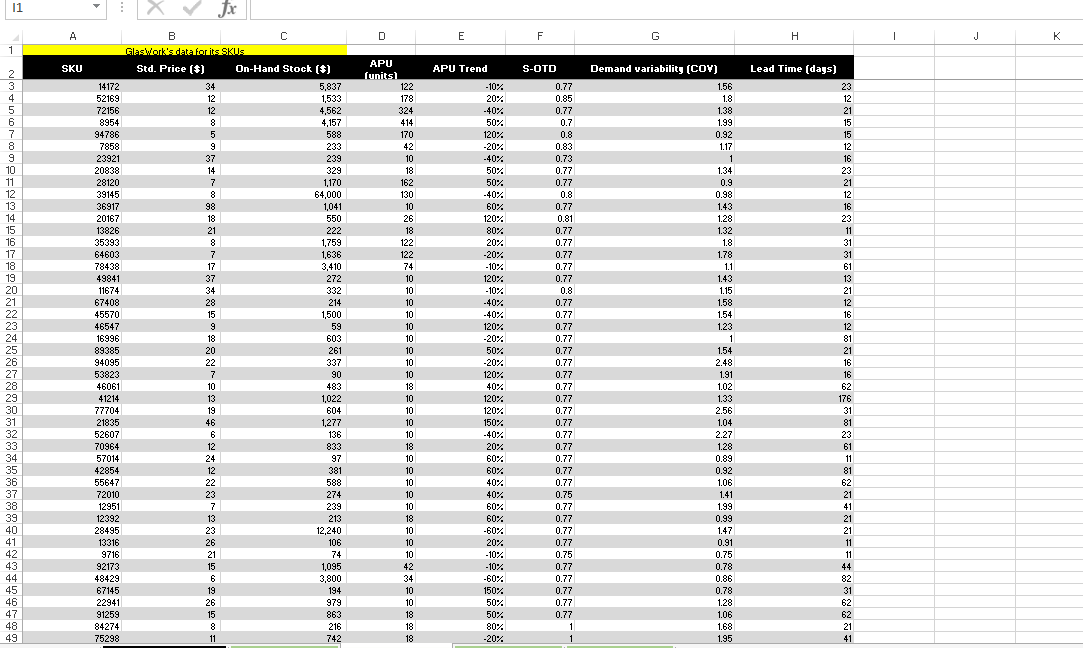

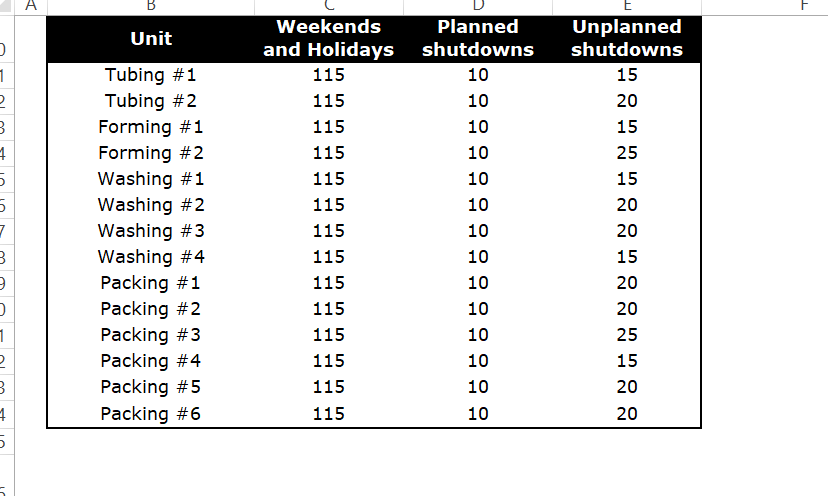

And the third area of concern is to identify if there is any capacity constraint for Fabricadas, the new facilities in Chicago, due to the sudden increase in demand for their products in the US. The Plant Controller feels the current capacity is not adequate to meet his forecasted demand. However, the VP Operations for MediCrystals is certain that there is enough capacity to meet the requirements. Your team needs to evaluate if there is genuinely a capacity constraint for Fabricadas and provide recommendations on how to maximize utilization to meet the demand at current capacity. Based on the operations of MediCrystals, provide recommendations on how it should meet the increase in demand for these products. Explain why the Plant Manager feels the capacity is inadequate and why the VP Operations feels the capacity is enough.

The products are needed for vaccines for other diseases, too. Glass vials are very hard and time-consuming to make. Sometimes, they take months for the manufacturing process. Even though coronavirus is the most pressing health issues in the world, MediCrystals wants to maintain a supply of their products for other critical vaccines which cannot be distorted for Covid 19 vaccine vials supply.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts