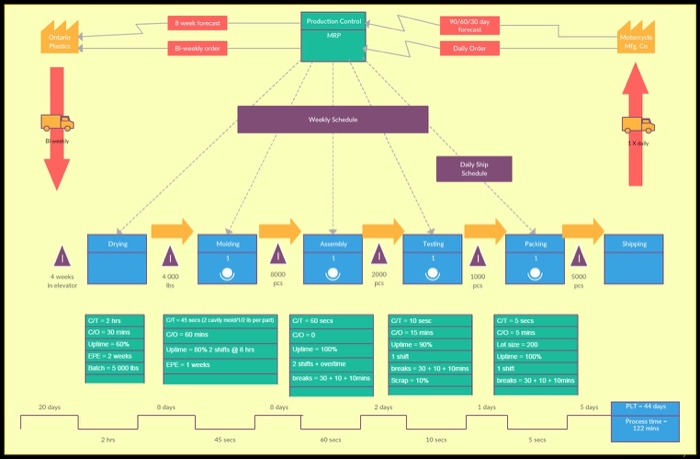

Question: Please choose one waste in sales and create value stream mapping (complete and comprehensive) and use words to explain it. Attached sample of value stream

Please choose one waste in sales and create value stream mapping (complete and comprehensive) and use words to explain it. Attached sample of value stream mapping.

Below are the Common sources of waste in sales include:

Defects Providing incorrect, unclear, or outdated information to a prospect.

Overproduction Over-communicating with a prospect to repeatedly gather information or clarify requests.

Waiting Time spent waiting on answers or information from other areas of your company (including marketing, production, inventory) that impact your ability to share information with prospects in a timely manner.

Under-utilized talent The amount of time sales reps spend on tasks that are not related to selling and engaging with prospects. This can include manually running processes, creating proposals, and looking for information.

Transportation The area of sales doesnt typically involve the transportation of parts or goods related to manufacturing. In sales, transportation waste can be equated to time wasted during the flow of information. For teams not using a CRM to automate and prioritize their communication efforts, there can be a great deal of transportation waste.

Inventory As a sales rep, your deliverables to your prospects are considered your "inventory." This can include providing quotes, pricing information, and negotiation deliverables in a timely manner.

Motion In Lean, motion waste occurs when more steps than necessary are taken to fulfill a task or statement of work. For your sales process, look for ways to expedite or automate tasks to improve motion such as setting up CRM integrations to reduce manual tasks.

Processing This type of waste occurs when the same set of data or information is processed multiple times. Do you find you or your team have to input the same information in several places? Do you have to go to multiple sources to pull standard reporting data? If so, these are areas where processing waste can be eliminated or reduced.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock