Question: PLEASE EXPLAIN EVERY STEP AND WHY EACH STEP IS REQUIRED!!! 11. Heat exchanger design (10 points) A shell-and-tube heat exchanger with two tube passes is

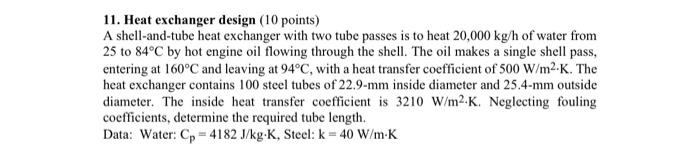

11. Heat exchanger design (10 points) A shell-and-tube heat exchanger with two tube passes is to heat 20,000 kg/h of water from 25 to 84C by hot engine oil flowing through the shell. The oil makes a single shell pass, entering at 160C and leaving at 94C, with a heat transfer coefficient of 500 W/m2.K. The heat exchanger contains 100 steel tubes of 22.9-mm inside diameter and 25.4-mm outside diameter. The inside heat transfer coefficient is 3210 W/m2.K. Neglecting fouling coefficients, determine the required tube length. Data: Water: Cp = 4182 J/kg.K, Steel: k = 40 W/mK

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts