Question: Please explain in-depth how supply chain managers can help mitigate these risks. That is, develop an action plan to mitigate these risks (maximum of two

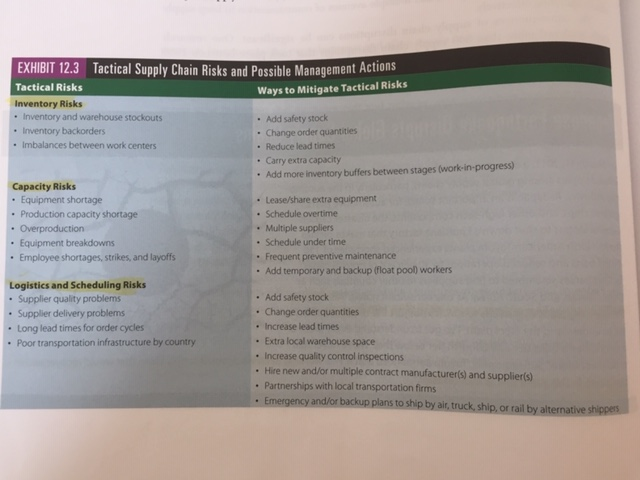

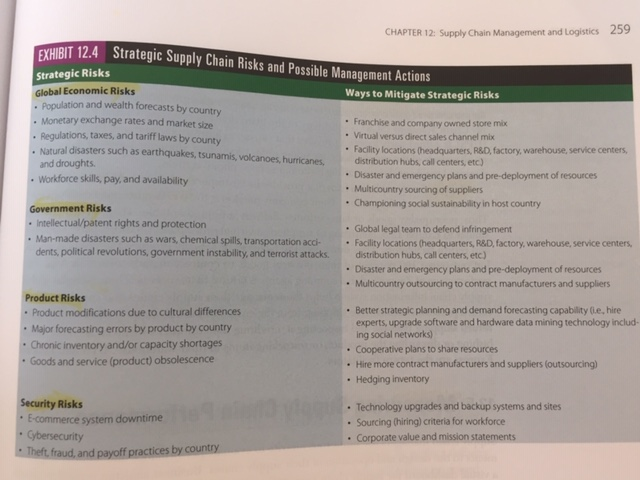

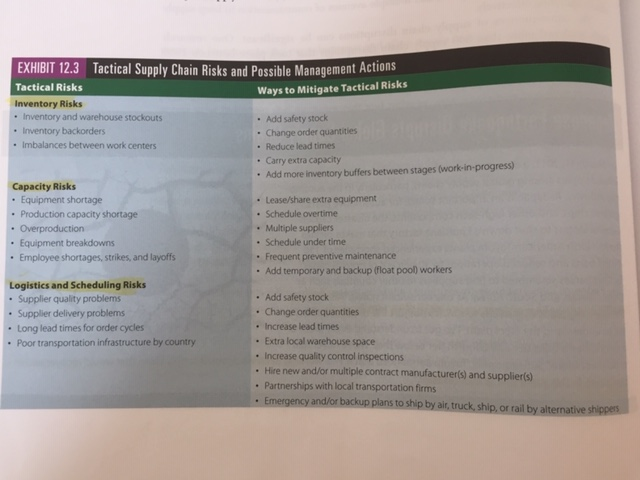

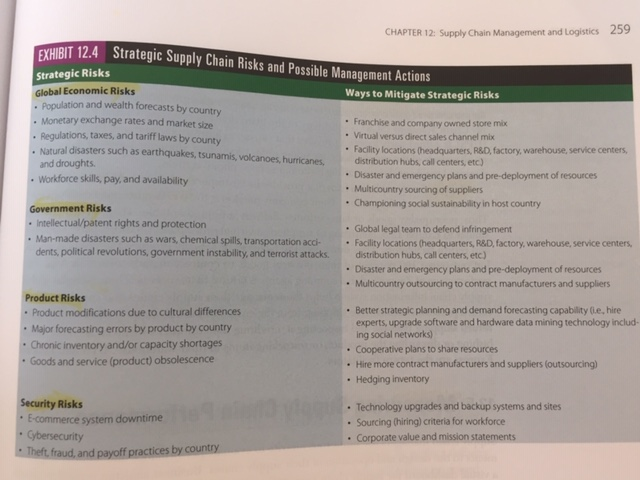

Please explain in-depth how supply chain managers can help mitigate these risks. That is, develop an action plan to mitigate these risks (maximum of two typed pages). You may utilize Exhibits 12.3 and 12.4 to answer this question.

Topic: "Inventory and warehouse stockouts and inventory backorders alternates all the time"

Ways to Mitigate Tactical Risks EXHIBIT 12.3 Tactical Supply Chain Risks and Possible Management Actions Tactical Risks Inventory Risks Inventory and warehouse stockouts Add safety stock Inventory backorders Change order quantities Imbalances between work centers Reduce lead times Carry extra capacity Add more inventory buffers between stages (work-in-progress) Capacity Risks Equipment shortage Lease/share extra equipment Production capacity shortage Schedule overtime Overproduction Multiple suppliers Equipment breakdowns Schedule under time Employee shortages, strikes, and layoffs Frequent preventive maintenance Add temporary and backup (float pool) workers Logistics and Scheduling Risks Supplier quality problems Add safety stock Supplier delivery problems Change order quantities tong lead times for order cycles Increase lead times . Poor transportation infrastructure by country Extra local warehouse space Increase quality control inspections Hire new and/or multiple contract manufacturer(s) and supplier(s) Partnerships with local transportation firms Emergency and/or backup plans to ship by air, truck ship, or rail by alternative shippers CHAPTER 12: Supply Chain Management and Logistics 259 EXHIBIT 12.4 Strategic Supply Chain Risks and possible Management Actions Strategic Risks Global Economic Risks Population and wealth forecasts by country Monetary exchange rates and market size Regulations, taxes, and tariff laws by county Natural disasters such as earthquakes, tsunamis, volcanoes, hurricanes, and droughts. Workforce skills, pay, and availability Ways to Mitigate Strategic Risks - . . Franchise and company owned store mix Virtual versus direct sales channel mix Facility locations headquarters, R&D, factory, warehouse, service centers, distribution hubs, call centers, etc.) Disaster and emergency plans and pre-deployment of resources Multicountry sourcing of suppliers Championing social sustainability in host country Government Risks Intellectual/patent rights and protection Man-made disasters such as wars, chemical spills, transportation acci dents, political revolutions, government instability, and terrorist attacks. Product Risks Product modifications due to cultural differences . Major forecasting errors by product by country Chronic inventory and/or capacity shortages . Goods and service (product) obsolescence Global legal team to defend infringement Facility locations (headquarters, R&D, factory, warehouse, service centers, distribution hubs, call centers, etc.) Disaster and emergency plans and pre-deployment of resources Multicountry outsourcing to contract manufacturers and suppliers Better strategic planning and demand forecasting capability Oe, hire experts, upgrade software and hardware data mining technology includ- ing social networks) Cooperative plans to share resources Hire more contract manufacturers and suppliers (outsourcing) Hedging inventory Security Risks E-commerce system downtime Cybersecurity Theft, fraud, and payoff practices by country Technology upgrades and backup systems and sites . Sourcing (hiring) criteria for workforce Corporate value and mission statements Ways to Mitigate Tactical Risks EXHIBIT 12.3 Tactical Supply Chain Risks and Possible Management Actions Tactical Risks Inventory Risks Inventory and warehouse stockouts Add safety stock Inventory backorders Change order quantities Imbalances between work centers Reduce lead times Carry extra capacity Add more inventory buffers between stages (work-in-progress) Capacity Risks Equipment shortage Lease/share extra equipment Production capacity shortage Schedule overtime Overproduction Multiple suppliers Equipment breakdowns Schedule under time Employee shortages, strikes, and layoffs Frequent preventive maintenance Add temporary and backup (float pool) workers Logistics and Scheduling Risks Supplier quality problems Add safety stock Supplier delivery problems Change order quantities tong lead times for order cycles Increase lead times . Poor transportation infrastructure by country Extra local warehouse space Increase quality control inspections Hire new and/or multiple contract manufacturer(s) and supplier(s) Partnerships with local transportation firms Emergency and/or backup plans to ship by air, truck ship, or rail by alternative shippers CHAPTER 12: Supply Chain Management and Logistics 259 EXHIBIT 12.4 Strategic Supply Chain Risks and possible Management Actions Strategic Risks Global Economic Risks Population and wealth forecasts by country Monetary exchange rates and market size Regulations, taxes, and tariff laws by county Natural disasters such as earthquakes, tsunamis, volcanoes, hurricanes, and droughts. Workforce skills, pay, and availability Ways to Mitigate Strategic Risks - . . Franchise and company owned store mix Virtual versus direct sales channel mix Facility locations headquarters, R&D, factory, warehouse, service centers, distribution hubs, call centers, etc.) Disaster and emergency plans and pre-deployment of resources Multicountry sourcing of suppliers Championing social sustainability in host country Government Risks Intellectual/patent rights and protection Man-made disasters such as wars, chemical spills, transportation acci dents, political revolutions, government instability, and terrorist attacks. Product Risks Product modifications due to cultural differences . Major forecasting errors by product by country Chronic inventory and/or capacity shortages . Goods and service (product) obsolescence Global legal team to defend infringement Facility locations (headquarters, R&D, factory, warehouse, service centers, distribution hubs, call centers, etc.) Disaster and emergency plans and pre-deployment of resources Multicountry outsourcing to contract manufacturers and suppliers Better strategic planning and demand forecasting capability Oe, hire experts, upgrade software and hardware data mining technology includ- ing social networks) Cooperative plans to share resources Hire more contract manufacturers and suppliers (outsourcing) Hedging inventory Security Risks E-commerce system downtime Cybersecurity Theft, fraud, and payoff practices by country Technology upgrades and backup systems and sites . Sourcing (hiring) criteria for workforce Corporate value and mission statements