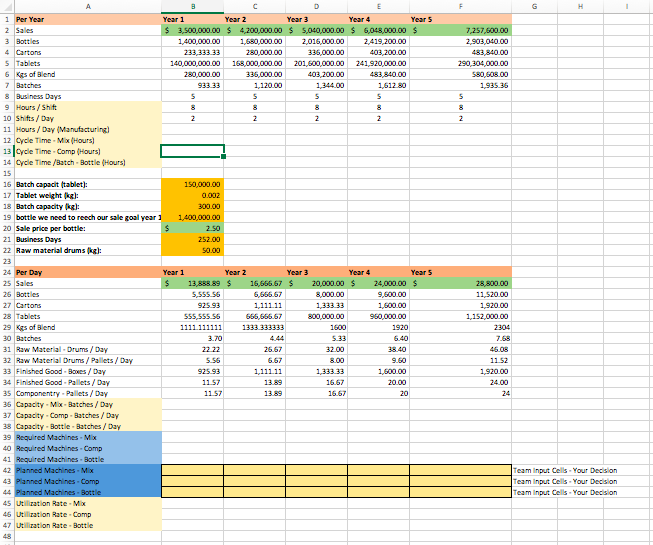

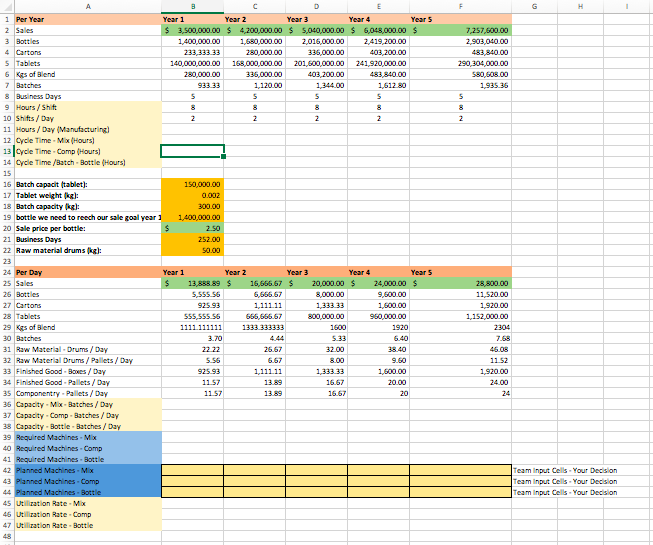

Question: Please find Hours / Day (Manufacturing) , Cycle Time - Mix (Hours), Cycle Time - Comp (Hours), Cycle Time /Batch - Bottle (Hours) and Capacity

Please find

Hours / Day (Manufacturing) , Cycle Time - Mix (Hours), Cycle Time - Comp (Hours), Cycle Time /Batch - Bottle (Hours)

and

| Capacity - Mix - Batches / Day |

| Capacity - Comp - Batches / Day |

| Capacity - Bottle - Batches / Day |

| Required Machines - Mix |

| Required Machines - Comp |

| Required Machines - Bottle |

| Planned Machines - Mix |

| Planned Machines - Comp |

| Planned Machines - Bottle |

| Utilization Rate - Mix |

| Utilization Rate - Comp |

| Utilization Rate - Bottle |

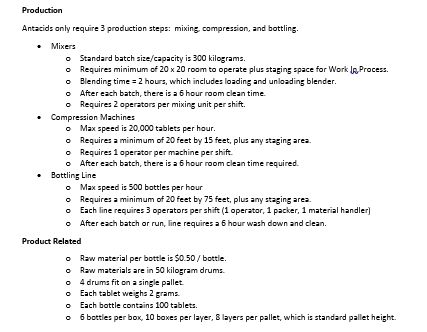

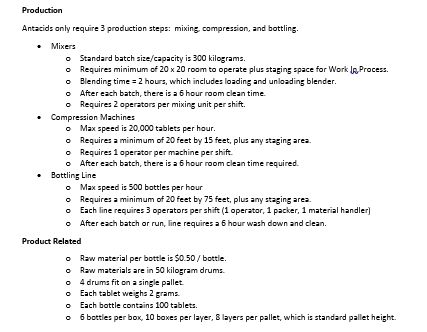

$ Ysari $ 3,500,000.00 1,400,000.00 233,333.33 140,000,000.00 280,000.00 933 33 Year 2 $ 4.200,000.00 1,680,000.00 280,000.00 168,000,000.00 336,000.00 1,120.00 $ 5,040,000.00 2,016,000.00 336,000.00 201,600,000.00 403,200.00 1 344.00 Year 4 $ 6,048,000.00 2,419,200.00 403,200.00 241 920,000.00 483,840.00 1612 80 7,257,800.00 2,903,040.00 483.840.00 290 300.000.00 580,608.00 1.935 35 1 Per Year 2 Sales 3 Bottles 4 Cartons s Tablets 6 kgs of Blend 7 Batches 8 Business Days 9 Hours / Shift 10 Shits / Day 11 Hours / Day (Manufacturing) 12 Cycle Time Mix ( Hours) 13 Cycle Time -Comp (Hours) 14 Cycle Time /Batch - Bottle Hours) 16 Batch capacit tablet): 17 Tablet weight (kg): 18 Batch capacity : 19 bottle we need to reech our sale goal year 1 cari 20 Sale price per bottle: 21 Business Days 22 Raw material drumstel: 150,000.00 0.002 300.00 1.400,000.00 252.00 50.00 23 $ $ Year 1 13.888.89 S.555.56 925.93 SSS SSS 56 1111111111 Year 2 Year 3 $ 16.666.67$ 20,000.00 6,666.67 8,000.00 1111 11 1333 33 656,656.67 800,000.00 1333333333 1600 24,000.00 9,800.00 1.600.00 990,000.00 28.800.00 11,520.00 1,920.00 1,152,000.00 2304 32.00 38.40 9.50 11.52 2222 5.56 925 93 11 57 1157 26.67 6.67 111111 13 59 13.39 1.600.00 20.00 20 1.920.00 24.00 16.57 24 Per Day 25 Sales 26 Bottles 27 Cartons 28 Tablets 29 Kas of Blend 30 Batches 31 Raw Material. Drums / Day 32 Raw Material Drums / Pallets / Day 33 Finished Good Boxes / Day 34 Finished Good Pallets / Day 35 Componenty-Pallets / Day 36 Capacity - Mix Batches / Day 37 Capacity. Comp - Batches / Day 38 Capacity - Bottle - Batches / Day 39 Required Machines - Mix 40 Required Machines - Comp 41 Required Machines - Bottle 42 Planned Machines - Mix 43 Planned Machines - Comp 44 Panned Machines - Bottle 45 Utilization Rate Mix 46 Utilization Rate - Comp 47 Utilization Rate - Bottle Team Input Cells - Your Decision Team Input Cells - Your Decision Team Input Cells - Your Decision Production Antacids only require 3 production steps: mixing, compression, and bottling Mixers o Standard batch size/capacity is 300 kilograms. o Requires minimum of 20 x 20 room to operate plus staging space for Work In Process. o Blending time = 2 hours, which includes loading and unloading blender. o After each batch, there is a 6 hour room clean time. o Requires 2 operators per mixing unit per shift. Compression Machines o Max speed is 20,000 tablets per hour. o Requires a minimum of 20 feet by 15 feet, plus any staging area. o Requires 1 operator per machine per shift. o After each batch, there is a 6 hour room clean time required. Bottling Line o Max speed is 500 bottles per hour o Requires a minimum of 20 feet by 75 feet, plus any staging area. o Each line requires 3 operators per shift (1 operator, 1 packer, 1 material handler o After each batch or run, line requires a 6 hour wash down and clean. Product Related o o o o o o Raw material per bottle is $0.50 / bottle. Raw materials are in 50 kilogram drums. 4 drums fit on a single pallet Each tablet weighs 2 grams. Each bottle contains 100 tablets. 6 bottles per box, 10 boxes per layer, & layers per pallet, which is standard pallet height. $ Ysari $ 3,500,000.00 1,400,000.00 233,333.33 140,000,000.00 280,000.00 933 33 Year 2 $ 4.200,000.00 1,680,000.00 280,000.00 168,000,000.00 336,000.00 1,120.00 $ 5,040,000.00 2,016,000.00 336,000.00 201,600,000.00 403,200.00 1 344.00 Year 4 $ 6,048,000.00 2,419,200.00 403,200.00 241 920,000.00 483,840.00 1612 80 7,257,800.00 2,903,040.00 483.840.00 290 300.000.00 580,608.00 1.935 35 1 Per Year 2 Sales 3 Bottles 4 Cartons s Tablets 6 kgs of Blend 7 Batches 8 Business Days 9 Hours / Shift 10 Shits / Day 11 Hours / Day (Manufacturing) 12 Cycle Time Mix ( Hours) 13 Cycle Time -Comp (Hours) 14 Cycle Time /Batch - Bottle Hours) 16 Batch capacit tablet): 17 Tablet weight (kg): 18 Batch capacity : 19 bottle we need to reech our sale goal year 1 cari 20 Sale price per bottle: 21 Business Days 22 Raw material drumstel: 150,000.00 0.002 300.00 1.400,000.00 252.00 50.00 23 $ $ Year 1 13.888.89 S.555.56 925.93 SSS SSS 56 1111111111 Year 2 Year 3 $ 16.666.67$ 20,000.00 6,666.67 8,000.00 1111 11 1333 33 656,656.67 800,000.00 1333333333 1600 24,000.00 9,800.00 1.600.00 990,000.00 28.800.00 11,520.00 1,920.00 1,152,000.00 2304 32.00 38.40 9.50 11.52 2222 5.56 925 93 11 57 1157 26.67 6.67 111111 13 59 13.39 1.600.00 20.00 20 1.920.00 24.00 16.57 24 Per Day 25 Sales 26 Bottles 27 Cartons 28 Tablets 29 Kas of Blend 30 Batches 31 Raw Material. Drums / Day 32 Raw Material Drums / Pallets / Day 33 Finished Good Boxes / Day 34 Finished Good Pallets / Day 35 Componenty-Pallets / Day 36 Capacity - Mix Batches / Day 37 Capacity. Comp - Batches / Day 38 Capacity - Bottle - Batches / Day 39 Required Machines - Mix 40 Required Machines - Comp 41 Required Machines - Bottle 42 Planned Machines - Mix 43 Planned Machines - Comp 44 Panned Machines - Bottle 45 Utilization Rate Mix 46 Utilization Rate - Comp 47 Utilization Rate - Bottle Team Input Cells - Your Decision Team Input Cells - Your Decision Team Input Cells - Your Decision Production Antacids only require 3 production steps: mixing, compression, and bottling Mixers o Standard batch size/capacity is 300 kilograms. o Requires minimum of 20 x 20 room to operate plus staging space for Work In Process. o Blending time = 2 hours, which includes loading and unloading blender. o After each batch, there is a 6 hour room clean time. o Requires 2 operators per mixing unit per shift. Compression Machines o Max speed is 20,000 tablets per hour. o Requires a minimum of 20 feet by 15 feet, plus any staging area. o Requires 1 operator per machine per shift. o After each batch, there is a 6 hour room clean time required. Bottling Line o Max speed is 500 bottles per hour o Requires a minimum of 20 feet by 75 feet, plus any staging area. o Each line requires 3 operators per shift (1 operator, 1 packer, 1 material handler o After each batch or run, line requires a 6 hour wash down and clean. Product Related o o o o o o Raw material per bottle is $0.50 / bottle. Raw materials are in 50 kilogram drums. 4 drums fit on a single pallet Each tablet weighs 2 grams. Each bottle contains 100 tablets. 6 bottles per box, 10 boxes per layer, & layers per pallet, which is standard pallet height