Question: please follow the solusion provided. (do not use the ones in chegg) A four-step process has processing times of 7, 6, 4, and 5 minutes

please follow the solusion provided. (do not use the ones in chegg)

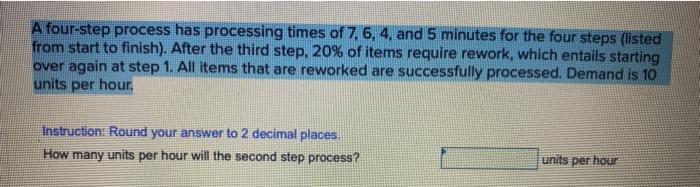

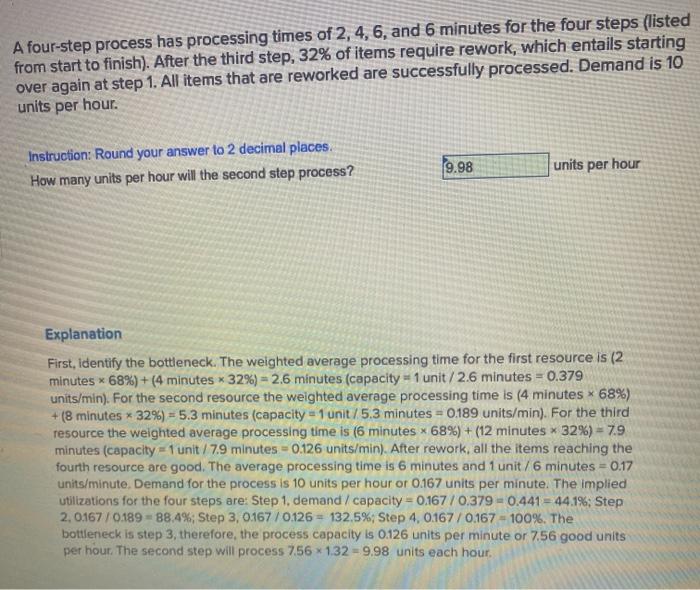

A four-step process has processing times of 7, 6, 4, and 5 minutes for the four steps (listed from start to finish). After the third step, 20% of items require rework, which entails starting over again at step 1. All items that are reworked are successfully processed. Demand is 10 units per hour. Instruction: Round your answer to 2 decimal places. How many units per hour will the second step process? units per hour A four-step process has processing times of 2, 4, 6, and 6 minutes for the four steps (listed from start to finish). After the third step, 32% of items require rework, which entails starting over again at step 1. All items that are reworked are successfully processed. Demand is 10 units per hour. Instruction: Round your answer to 2 decimal places. How many units per hour will the second step process? 9.98 units per hour Explanation First, identify the bottleneck. The weighted average processing time for the first resource is (2 minutes 68%) + (4 minutes * 32%) - 2.6 minutes (capacity = 1 unit/2.6 minutes = 0.379 units/min). For the second resource the weighted average processing time is (4 minutes * 68%) + (8 minutes * 32%) = 5.3 minutes (capacity = 1 unit 75.3 minutes = 0.189 units/min). For the third resource the weighted average processing time is (6 minutes * 68%) + (12 minutes * 32%) = 7.9 minutes (capacity 1 unit / 7.9 minutes - 0.126 units/min). After rework, all the items reaching the fourth resource are good. The average processing time is 6 minutes and 1 unit /6 minutes = 0.17 units/minute. Demand for the process is 10 units per hour or 0.167 units per minute. The implied utilizations for the four steps are: Step 1. demand / capacity = 0.167 / 0.379 = 0.441 = 44.1%; Step 2.0.167/0.189 = 88.4%; Step 3, 0167 / 0.126 = 132.5%; Step 4, 0.167 / 0.167 = 100%. The bottleneck is step 3, therefore, the process capacity is 0.126 units per minute or 7.56 good units per hour. The second step will process 7.56 * 1.329.98 units each hour