Question: PLEASE HELP!!!!! INDUSTRIAL ENGINEERING Ten jobs must be processed by two machines sequentially. Each job is processed by machine 1 first. After the job is

PLEASE HELP!!!!!

INDUSTRIAL ENGINEERING

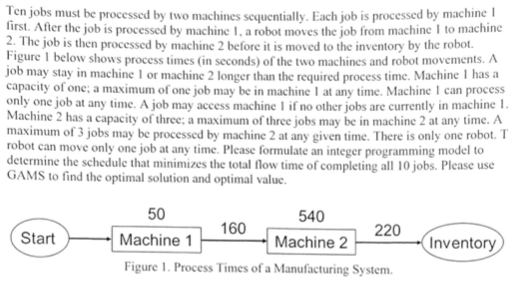

Ten jobs must be processed by two machines sequentially. Each job is processed by machine 1 first. After the job is processed by machine 1, a robot moves the job from machine I to machine 2. The job is then processed by machine 2 before it is moved to the inventory by the robot. Figure 1 below shows process times (in seconds) of the two machines and robot movements. A job may stay in machine 1 or machine 2 longer than the required process time. Machine 1 has a capacity of one; a maximum of one job may be in machine I at any time. Machine 1 can process only one job at any time. A job may access machine I if no other jobs are currently in machine 1. Machine 2 has a capacity of three; a maximum of three jobs may be in machine 2 at any time. A maximum of 3 jobs may be processed by machine 2 at any given time. There is only one robot. T robot can move only one job at any time. Please formulate an integer programming model to determine the schedule that minimizes the total flow time of completing all 10 jobs. Please use GAMS to find the optimal solution and optimal value. 50 540 160 220 Start Machine 1 Machine 2 Inventory Figure 1. Process Times of a Manufacturing SystemStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock