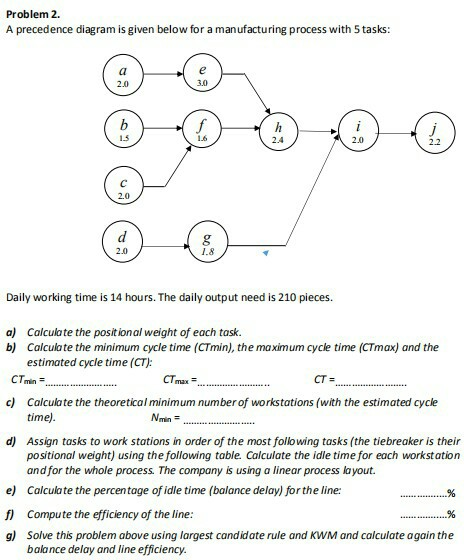

Question: please help Problem 2. A precedence diagram is given below for a manufacturing process with 5 tasks: Daily working time is 14 hours. The daily

please help

Problem 2. A precedence diagram is given below for a manufacturing process with 5 tasks: Daily working time is 14 hours. The daily output need is 210 pieces. CT a) Calculate the positional weight of each task. b) Calculate the minimum cycle time (CTmin), the maximum cycle time (CTmax) and the estimated cycle time (CT): CT CT max- c) Calculate the theoretical minimum number of workstations (with the estimated cycle time). N in .............. d) Assign tasks to work stations in order of the most following tasks (the tiebreaker is their positional weight) using the following table Calculate the idle time for each workstation and for the whole process. The company is using a linear process layout. e) Calculate the percentage of idle time (balance delay) for the line: Compute the efficiency of the line: a) Solve this problem above using largest candidate rule and KWM and calculate again the balance delay and line efficiencyStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock