Question: Please I need help on formulate this problems 1-decision variables 2-objectives functions 3-constraints (no need for numerical solution) Assume that you are an operations researcher

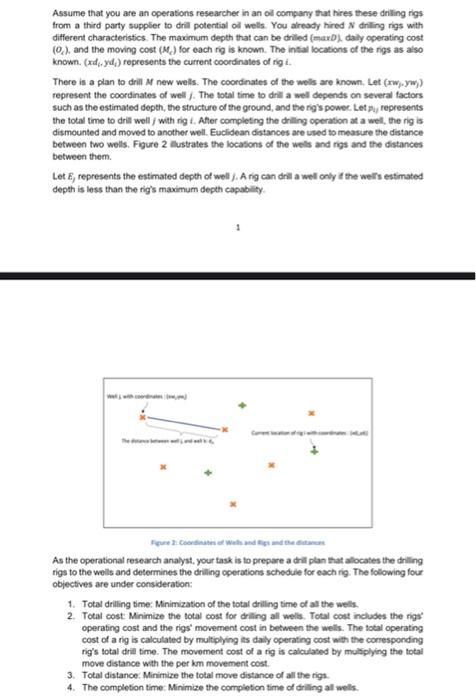

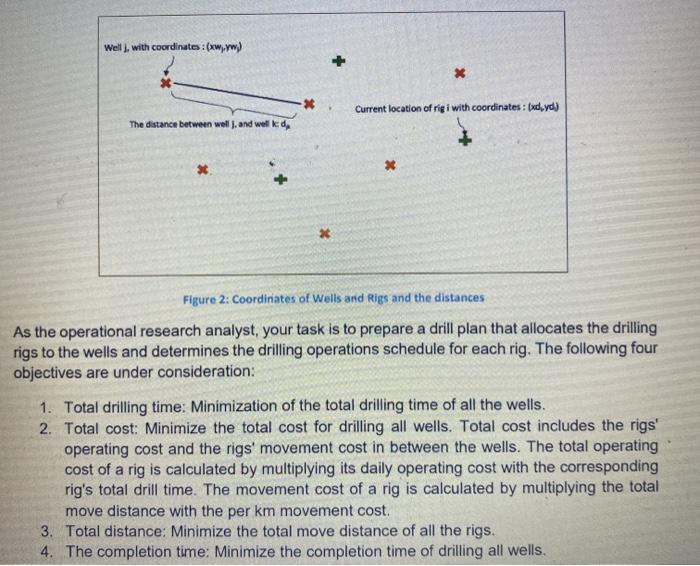

Please I need help on formulate this problems 1-decision variables 2-objectives functions 3-constraints (no need for numerical solution) Assume that you are an operations researcher in an ol company that hires these driving rigs from a third party supplier to drill potential oil weils. You already hired Ndriling rigs with different characteristics. The maximum depth that can be drilled (max) daily operating cost (0.)and the moving cost (M) for each rig is known. The initial locations of the rigs as also known. (xd.yd.) represents the current coordinates of rigi. There is a plan to drill M new wels. The coordinates of the wols are known. Let (ww.yw) represent the coordinates of well. The total time to drill a well depends on several factors such as the estimated depth, the structure of the ground, and the rig's power. Letr, represents the total time to drill well with rig. Aller completing the drilling operation at a well, the rig is dismounted and moved to another well. Euclidean distances are used to measure the distance between two wells. Figure 2 llustrates the locations of the wells and rigs and the distances between them. Let E, represents the estimated depth of well. A rig can drill a well only if the wells estimated depth is less than the rig's maximum depth capability 1 purez-Cortinates wat and the As the operational research analyst, your task is to prepare a drill plan that allocates the drilling rigs to the weils and determines the drilling operations schedule for each rig. The following fou objectives are under consideration: 1. Total drilling time: Minimization of the total drilling time of all the wells 2. Total cost: Minimize the total cost for drilling all wells. Total cost includes the rigs operating cost and the rigs' movement cost in between the wells. The total operating cost of a rig is calculated by multiplying its daily operating cost with the corresponding rig's total drill time. The movement cost of a nig is calculated by multiplying the total move distance with the per km movement cost. 3. Total distance: Minimize the total move distance of all the rigs 4. The completion time: Minimize the completion time of drilling all wells Assume that you are an operations researcher in an oil company that hires these drilling rigs from a third party supplier to drill potential oil wells. You already hired N drilling rigs with different characteristics. The maximum depth that can be drilled (maxD), daily operating cost (Oc), and the moving cost (Mc) for each rig is known. The initial locations of the rigs as also known. (xdi, yd) represents the current coordinates of rig i. There is a plan to drill M new wells. The coordinates of the wells are known. Let (xW;,yw;) represent the coordinates of wellj. The total time to drill a well depends on several factors such as the estimated depth, the structure of the ground, and the rig's power. Let pij represents the total time to drill well with rig i. After completing the drilling operation at a well, the rig is dismounted and moved to another well. Euclidean distances are used to measure the distance between two wells. Figure 2 illustrates the locations of the wells and rigs and the distances between them Let E, represents the estimated depth of well). A rig can drill a well only if the well's estimated depth is less than the rig's maximum depth capability, Well], with coordinates: (xw.y) Current location of rig i with coordinates: (xd, yd) The distance between well J, and well de X Figure 2: Coordinates of Wells and Rigs and the distances As the operational research analyst, your task is to prepare a drill plan that allocates the drilling rigs to the wells and determines the drilling operations schedule for each rig. The following four objectives are under consideration: 1. Total drilling time: Minimization of the total drilling time of all the wells. 2. Total cost: Minimize the total cost for drilling all wells. Total cost includes the rigs' operating cost and the rigs' movement cost in between the wells. The total operating cost of a rig is calculated by multiplying its daily operating cost with the corresponding rig's total drill time. The movement cost of a rig is calculated by multiplying the total move distance with the per km movement cost. 3. Total distance: Minimize the total move distance of all the rigs. 4. The completion time: Minimize the completion time of drilling all wells