Question: PROBLEM B: AN INVENTORY MANAGEMENT PROBLEM In the following problem, find the best ordering policies: A company that sells a single product would like to

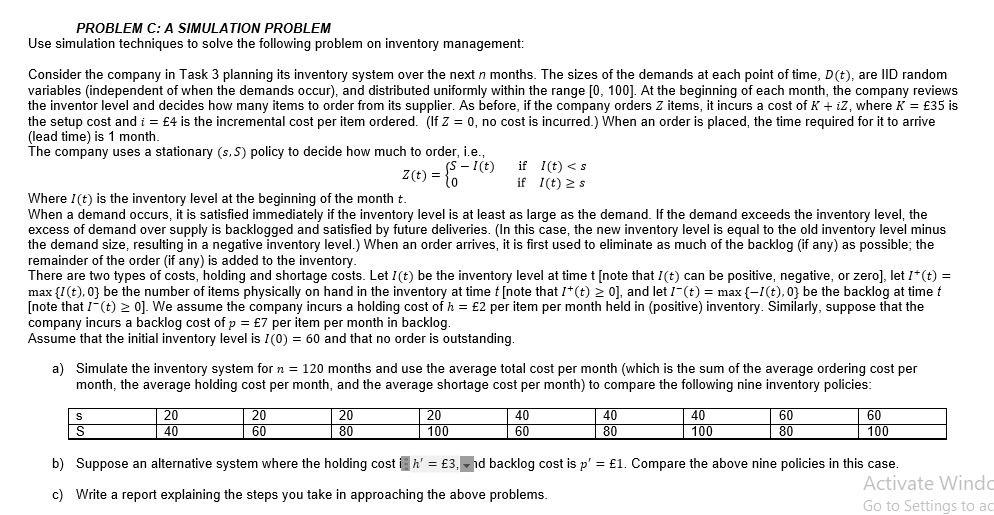

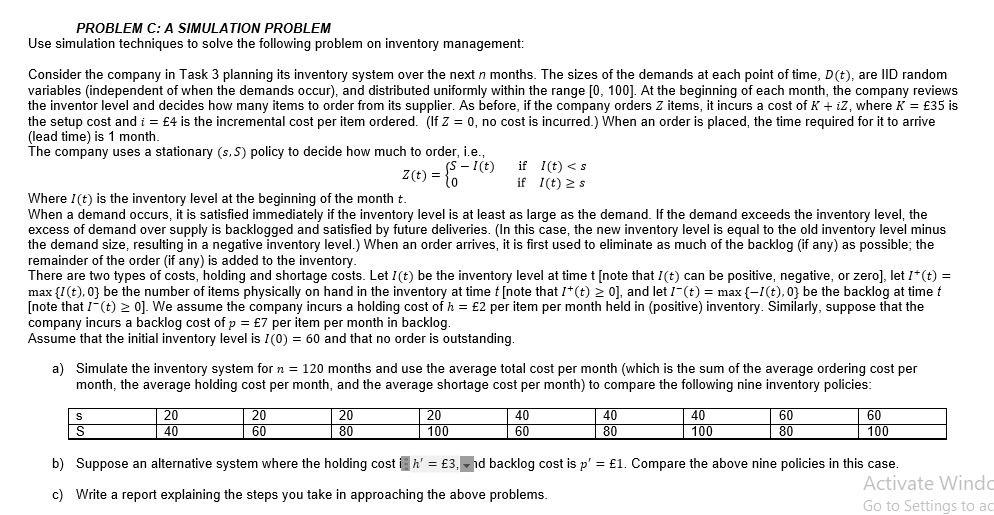

PROBLEM B: AN INVENTORY MANAGEMENT PROBLEM In the following problem, find the best ordering policies: A company that sells a single product would like to decide how many items it should have in inventory for each of the next 13 months. The company receives a lump-sum demand for every month in advancee so the comnanv knows the demand in the next 1.3 month as follows Given that the information for demand is known in advance, the company can decide how many items to order from its supplier in which month. If the company orders Z items, it incurs a cost of K+iZ, where K=35 is the setup cost (transportation, administrative, etc) and i=4 is the incremental purchase cost per item ordered. (If Z=0, no cost is incurred.) When an order is placed, the time required for it to arrive (lead time) is 1 month. (Therefore, the order placed at t=1 will arrive at the beginning of t=2 ). The company cannot incur backlog, that is, it needs to make sure that there is always enough inventory to satisfy the demands. The demand of each month occurs at the beginning of the month and that is the time when last month order arrives. There is holding costs for keeping inventory. Let I(t) be the inventory level at the end of month t [note that I(t) can be positive, or zero but not negative]. We assume the company incurs a holding cost h=1 per item per month held in (positive) inventory for a month. Assume that the initial inventory level is I(0)=50 and that no order is outstanding. a) Determine the best ordering policy. b) Write a report explaining the steps you take in approaching the above problems. Consider the company in Task 3 planning its inventory system over the next n months. The sizes of the demands at each point of time, D(t), are IID random variables (independent of when the demands occur), and distributed uniformly within the range [0,100]. At the beginning of each month, the company reviews the inventor level and decides how many items to order from its supplier. As before, if the company orders Z items, it incurs a cost of K+iZ, where K=35 is the setup cost and i=4 is the incremental cost per item ordered. (If Z=0, no cost is incurred.) When an order is placed, the time required for it to arrive (lead time) is 1 month. The company uses a stationary (s,S) policy to decide how much to order, i.e., Z(t)={SI(t)0ifI(t)