Question: Question 1) **Please also find planned orders (it won't show up until I fill the rest of the boxes) Question 2) **for question 2 I

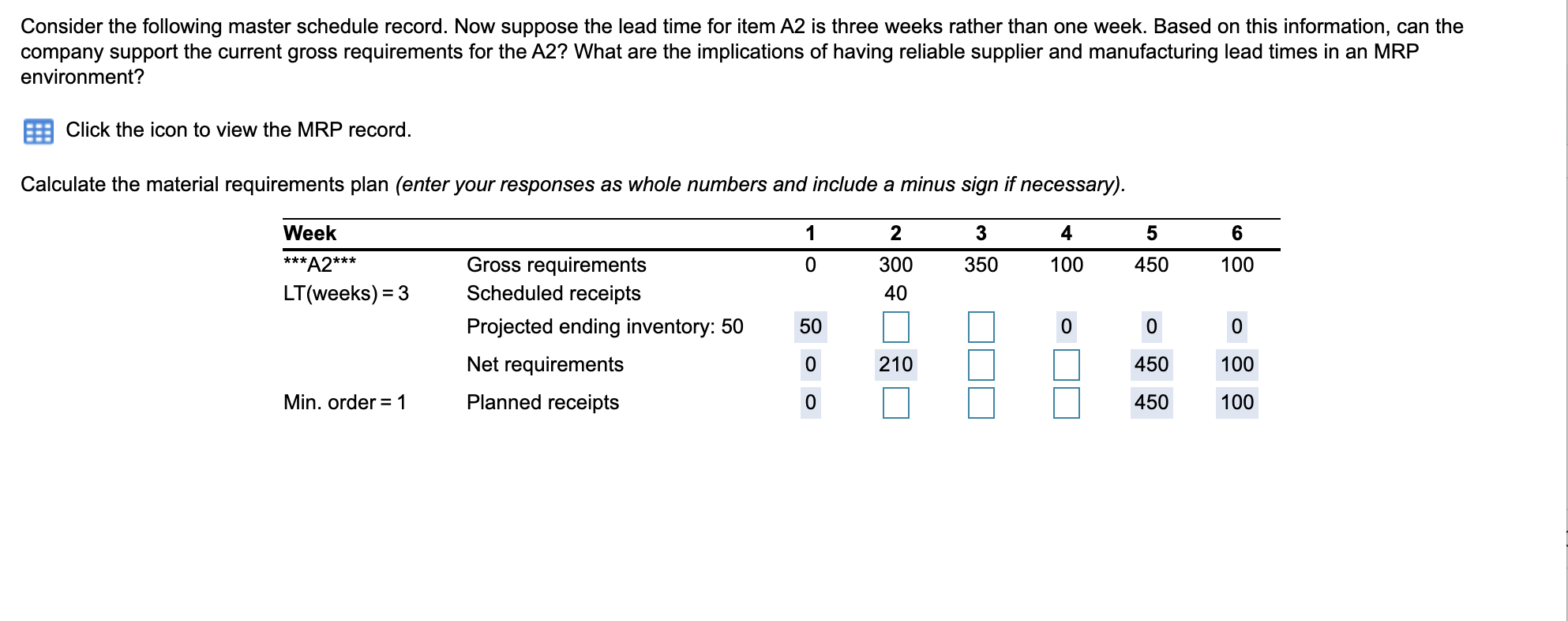

Question 1)

**Please also find planned orders (it won't show up until I fill the rest of the boxes)

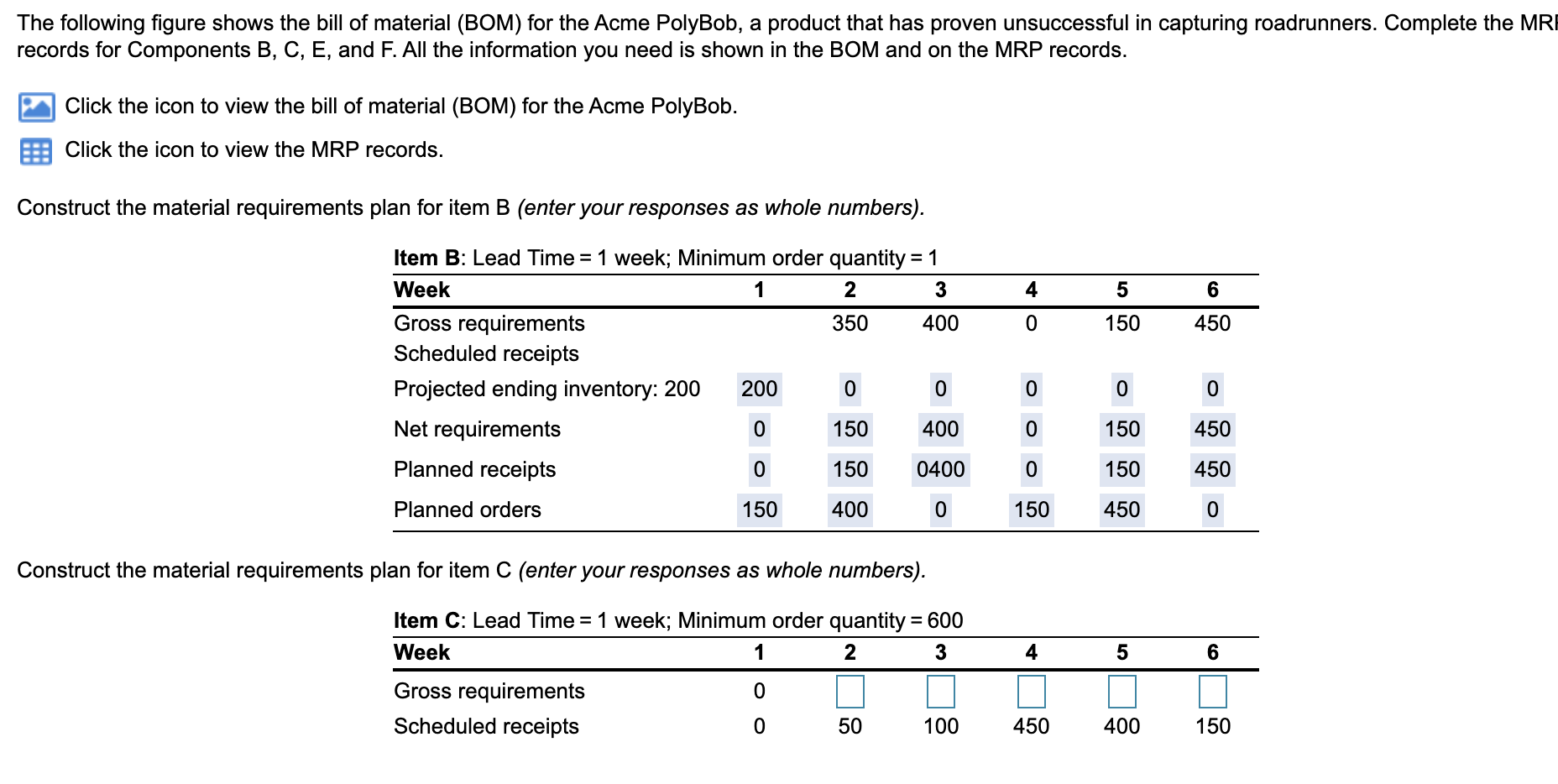

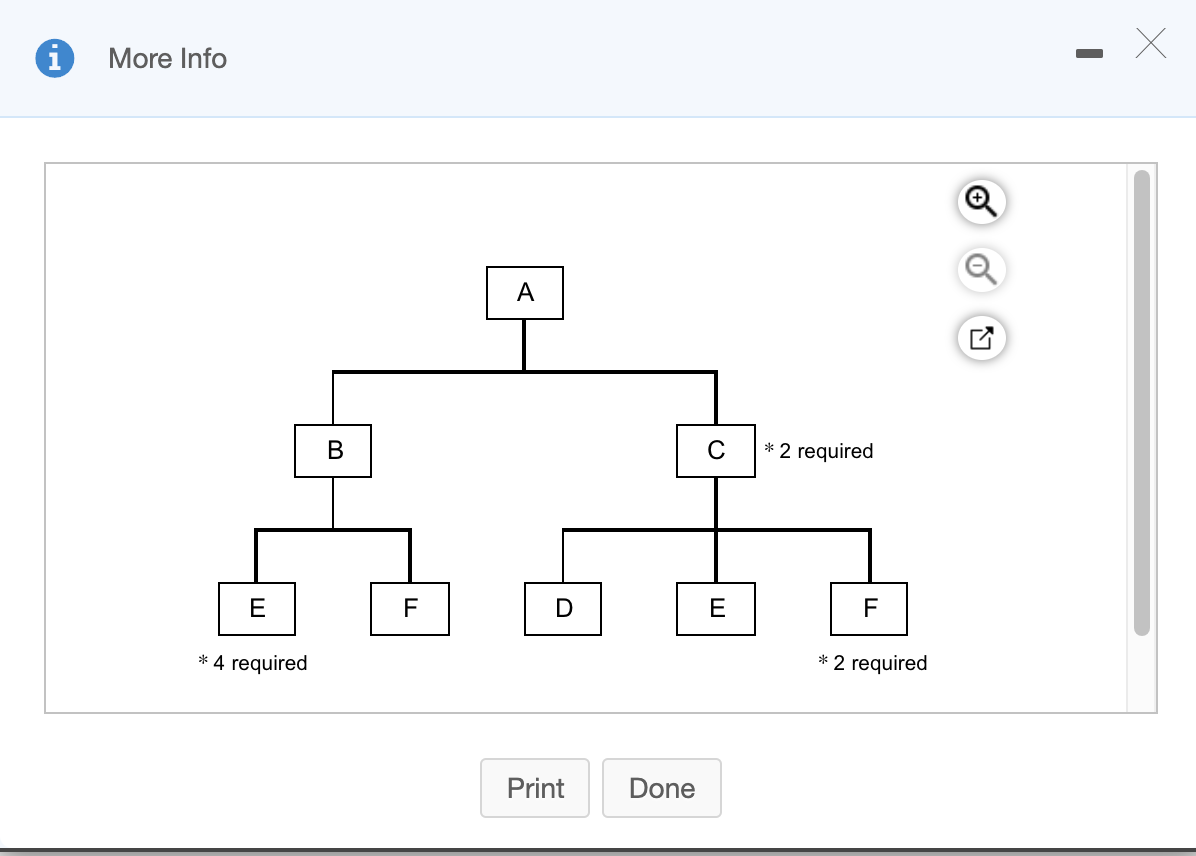

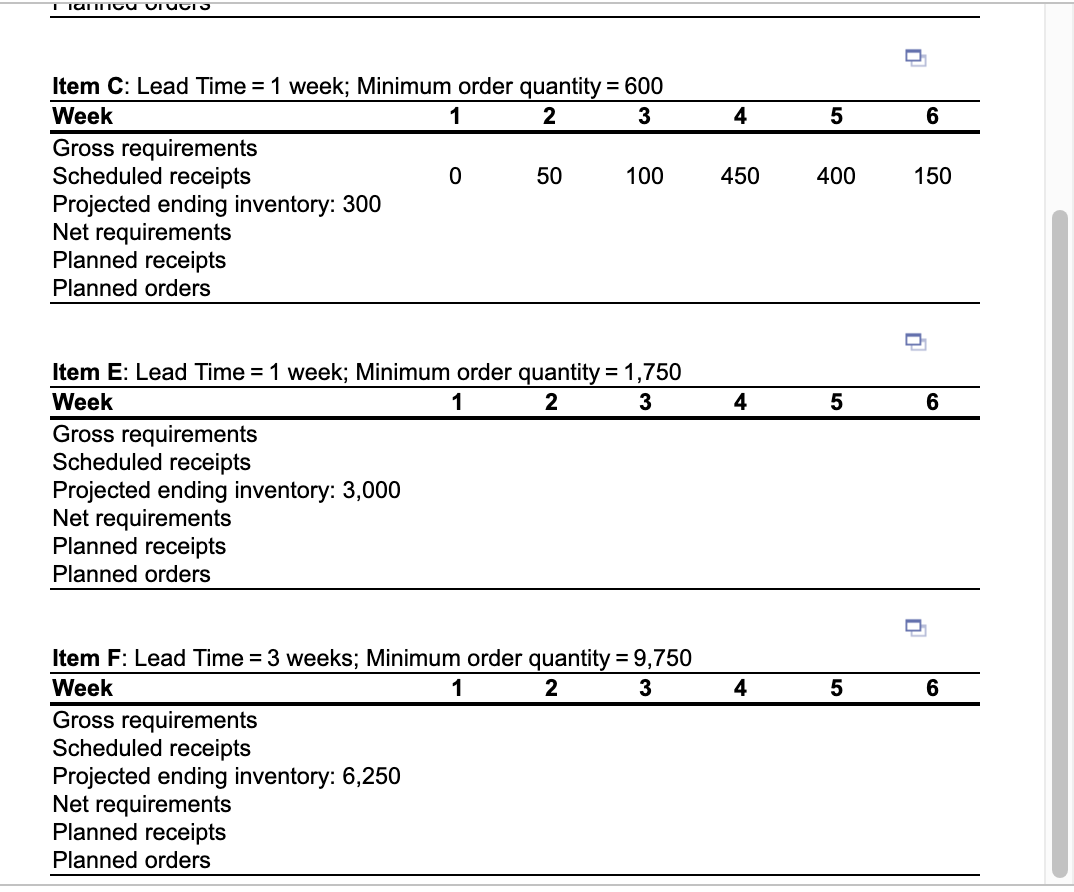

Question 2)

**for question 2 I need to fill in the charts for item C E and F

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts