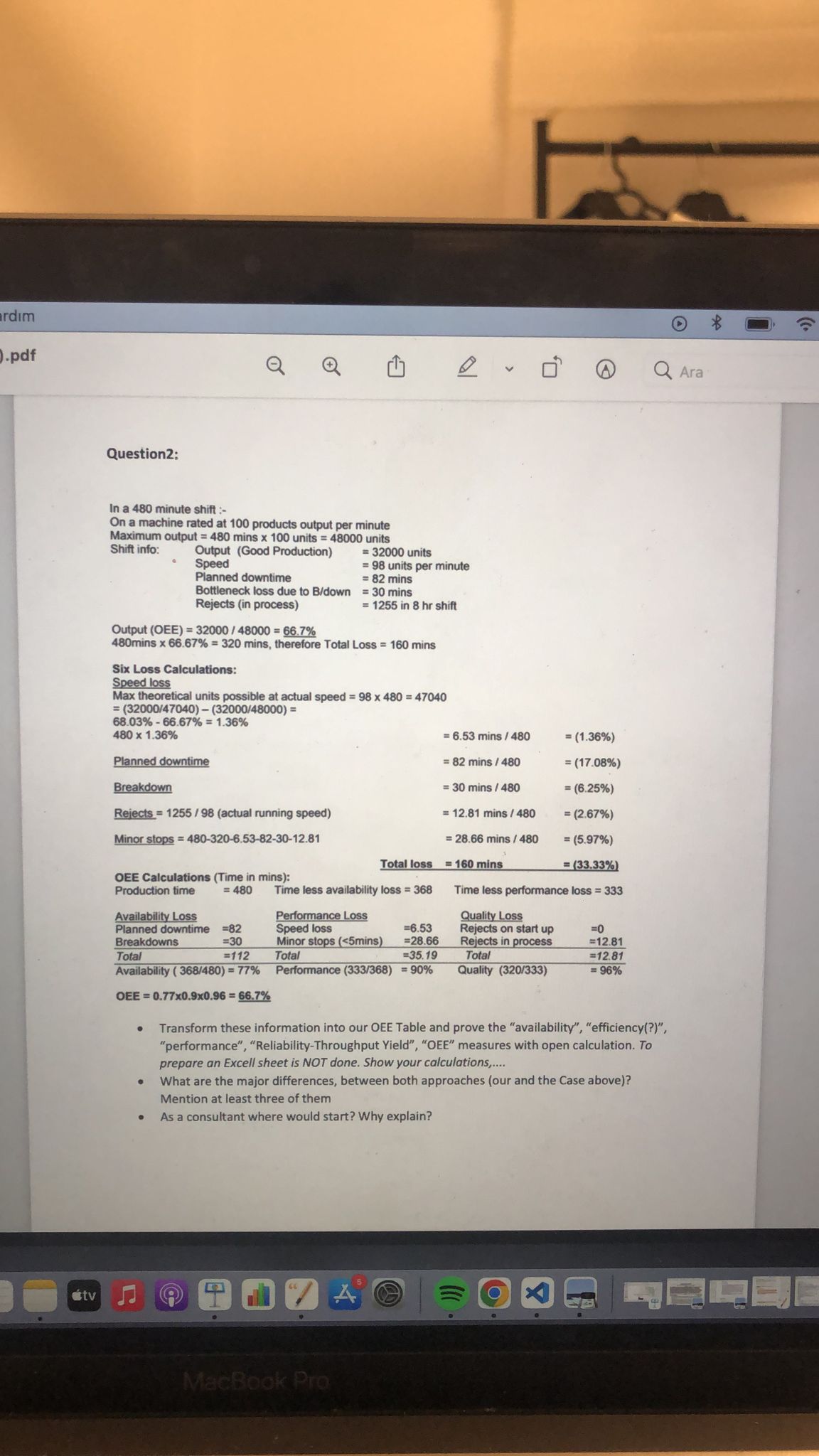

Question: Question 2 : In a 4 8 0 minute shift : - On a machine rated at 1 0 0 products output per minute Maximum

Question:

In a minute shift :

On a machine rated at products output per minute

Maximum output mins units units

Shift info:

Output Good Production

Speed

Planned downtime

Bottleneck loss due to Bdown

Rejects in process

units

units per minute

mins

mins

in shift

Output OEE

minsmins, therefore Total Loss mins

Six Loss Calculations:

Speed loss

Max theoretical units possible at actual speed

Planned downtime

Breakdown

Rejects actual running speed

Minor stops

OEE Calculations Time in mins:

Production time Time less availability loss Time less performance loss

OEE

Transform these information into our OEE Table and prove the "availability", "efficiency

"performance", "ReliabilityThroughput Yield", "OEE" measures with open calculation. To

prepare an Excell sheet is NOT done. Show your calculations,....

What are the major differences, between both approaches our and the Case above

Mention at least three of them

As a consultant where would start? Why explain?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock