Question: Question 4 - Material Requirements Planning ( 1 0 marks ) A manufacturing company produces product A that comprises of a number of components as

Question Material Requirements Planning marks

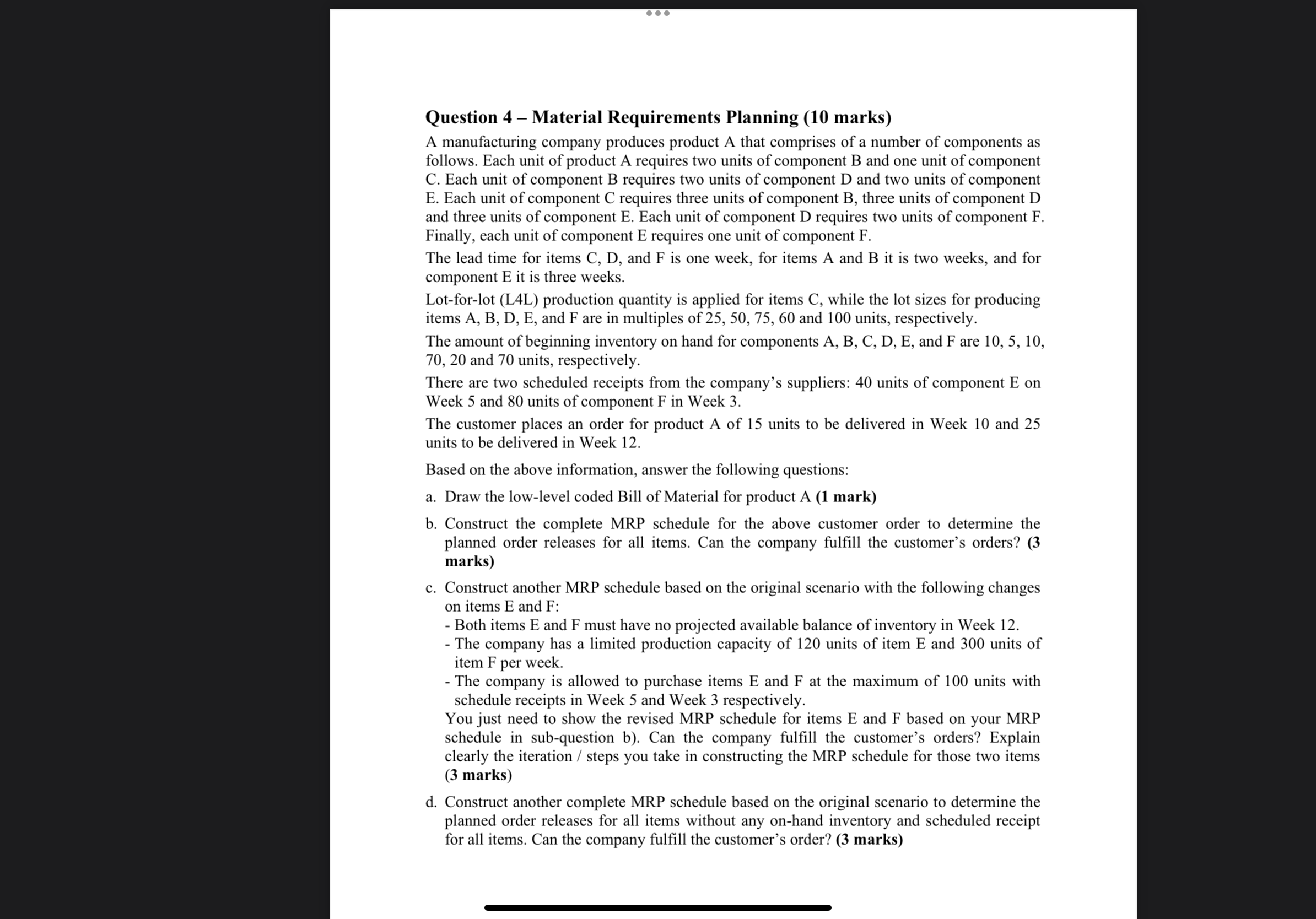

A manufacturing company produces product A that comprises of a number of components as follows. Each unit of product A requires two units of component B and one unit of component C Each unit of component B requires two units of component D and two units of component E Each unit of component C requires three units of component B three units of component D and three units of component E Each unit of component D requires two units of component F Finally, each unit of component E requires one unit of component F

The lead time for items C D and F is one week, for items A and B it is two weeks, and for component E it is three weeks.

Lotforlot LL production quantity is applied for items C while the lot sizes for producing items A B D E and F are in multiples of and units, respectively.

The amount of beginning inventory on hand for components A B C D E and F are and units, respectively.

There are two scheduled receipts from the company's suppliers: units of component E on Week and units of component F in Week

The customer places an order for product A of units to be delivered in Week and units to be delivered in Week

Based on the above information, answer the following questions:

a Draw the lowlevel coded Bill of Material for product A mark

b Construct the complete MRP schedule for the above customer order to determine the planned order releases for all items. Can the company fulfill the customer's orders? marks

c Construct another MRP schedule based on the original scenario with the following changes on items E and F:

Both items E and F must have no projected available balance of inventory in Week

The company has a limited production capacity of units of item E and units of item F per week.

The company is allowed to purchase items E and F at the maximum of units with schedule receipts in Week and Week respectively.

You just need to show the revised MRP schedule for items E and F based on your MRP schedule in subquestion b Can the company fulfill the customer's orders? Explain clearly the iteration steps you take in constructing the MRP schedule for those two items marks

d Construct another complete MRP schedule based on the original scenario to determine the planned order releases for all items without any onhand inventory and scheduled receipt for all items. Can the company fulfill the customer's order?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock