Question: Question In Operation Management ... Greetings... DO NOT RESPOND TO MY QUESTION UNTIL YOU UNDERSTAND WHAT GUJU - DALLA FORMAT IS AND HOW TO

Question In Operation Management ...

Greetings... DO NOT RESPOND TO MY QUESTION UNTIL YOU UNDERSTAND WHAT " GUJU - DALLA FORMAT" IS AND HOW TO RESPOND IN IT; IF YOU DO, YOUR QUESTION WILL BE DOWNVOTED .

Please respond as soon as possible... Only in the " GUJU - DALLA Format," that is, GUJ INNT... Step-by-Step Solution...

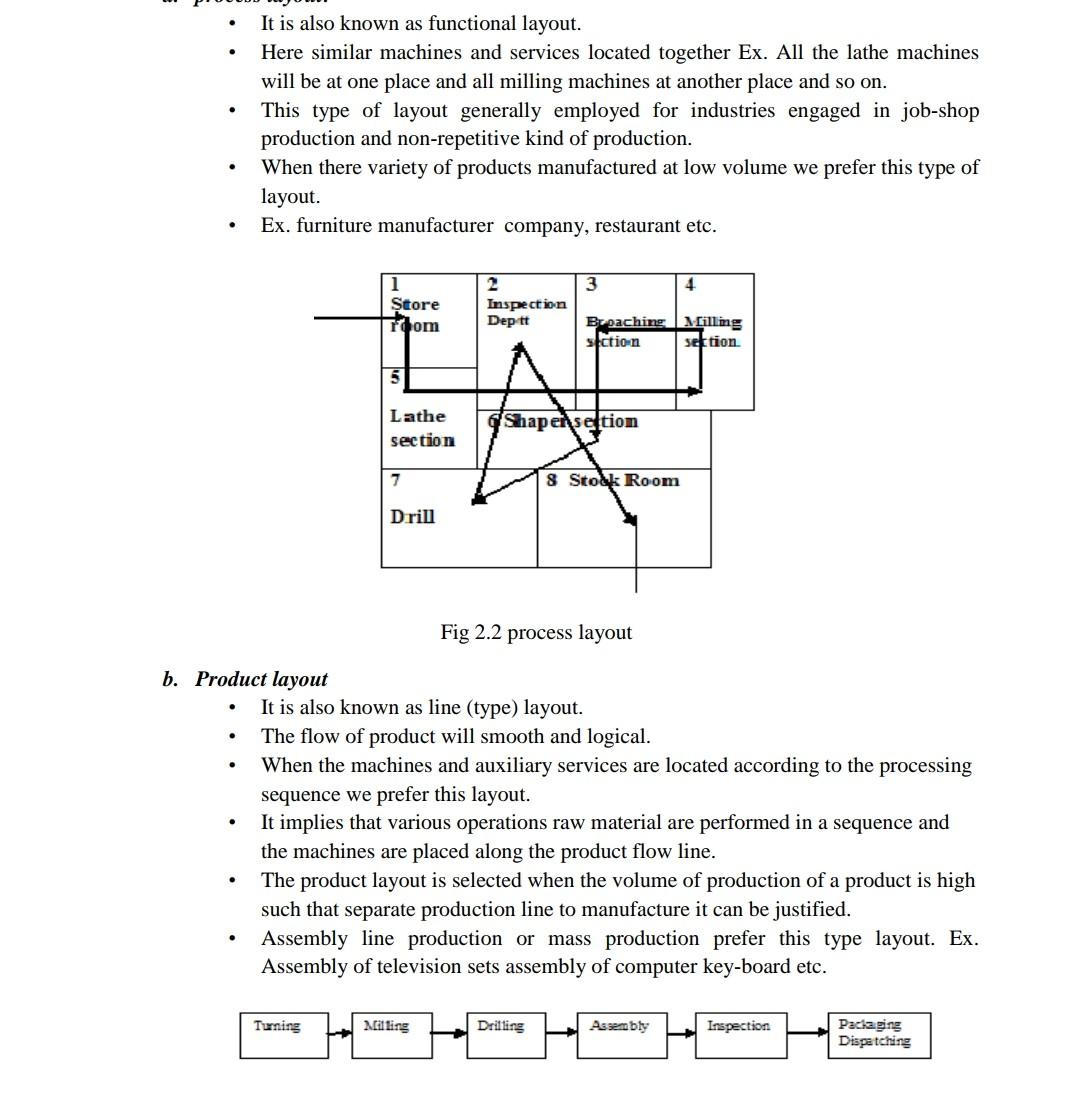

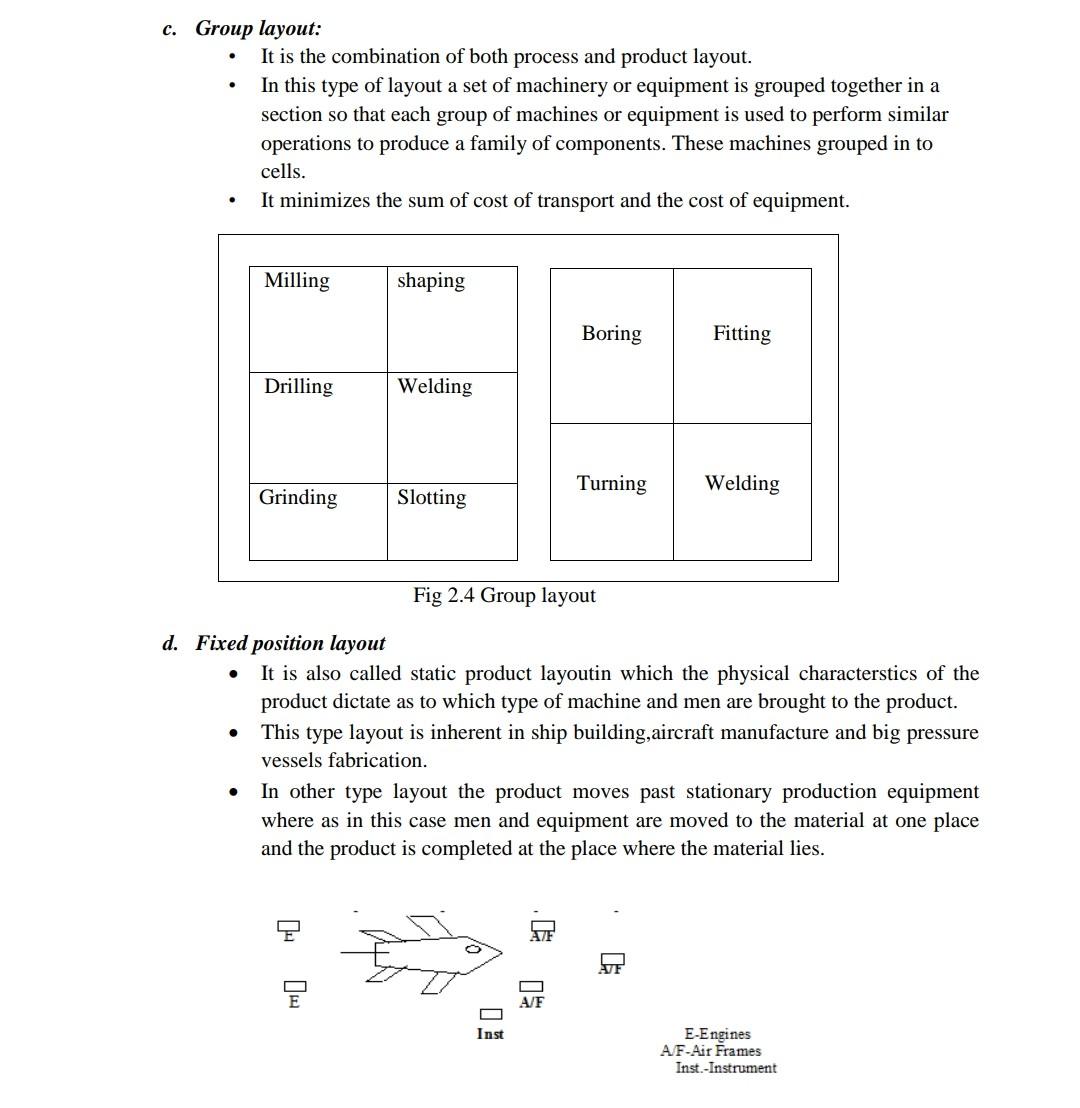

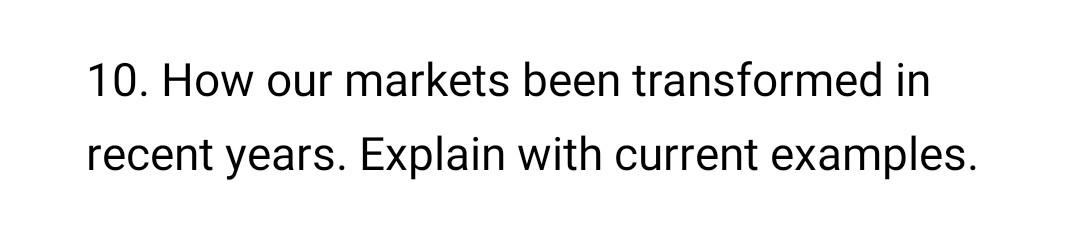

. . It is also known as functional layout. Here similar machines and services located together Ex. All the lathe machines will be at one place and all milling machines at another place and so on. This type of layout generally employed for industries engaged in job-shop production and non-repetitive kind of production. When there variety of products manufactured at low volume we prefer this type of layout. Ex. furniture manufacturer company, restaurant etc. 3 4 Store Toom 2 Inspection Deptt Broaching Milling Suction sektion Lathe section Shapen sestion 7. 8 Stod Room Drill Fig 2.2 process layout b. Product layout It is also known as line (type) layout. The flow of product will smooth and logical. When the machines and auxiliary services are located according to the processing sequence we prefer this layout. It implies that various operations raw material are performed in a sequence and the machines are placed along the product flow line. The product layout is selected when the volume of production of a product is high such that separate production line to manufacture it can be justified. Assembly line production or mass production prefer this type layout. Ex. Assembly of television sets assembly of computer key-board etc. . . Tuning Afilling Drilling Assembly Inspection Packaging Dispatching c. Group layout: It is the combination of both process and product layout. In this type of layout a set of machinery or equipment is grouped together in a section so that each group of machines or equipment is used to perform similar operations to produce a family of components. These machines grouped in to cells. It minimizes the sum of cost of transport and the cost of equipment. Milling shaping Boring Fitting Drilling Welding Turning Welding Grinding Slotting Fig 2.4 Group layout d. Fixed position layout It is also called static product layoutin which the physical characterstics of the product dictate as to which type of machine and men are brought to the product. This type layout is inherent in ship building, aircraft manufacture and big pressure vessels fabrication. In other type layout the product moves past stationary production equipment where as in this case men and equipment are moved to the material at one place and the product is completed at the place where the material lies. . Inst E-Engines AF-Air Frames Inst.-Instrument 10. How our markets been transformed in recent years. Explain with current examples

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts