Question: Renova's problem is to develop a disaggregate production plan (Economic Lot Schedule) for five SKUs (white, blue, red, green, and pink) of a product

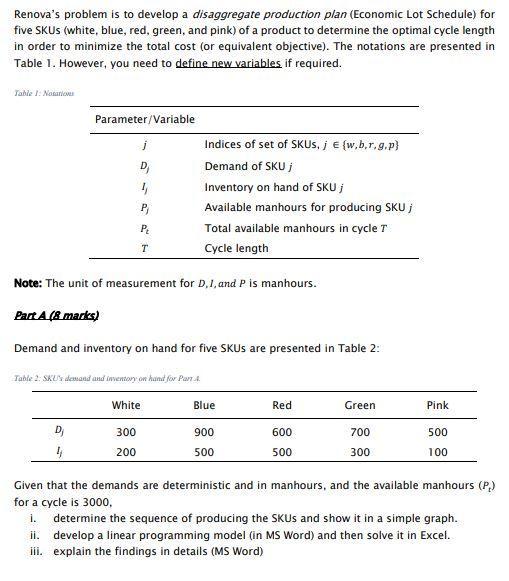

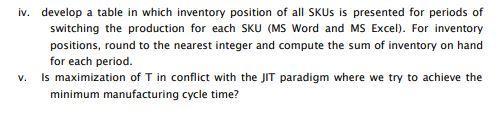

Renova's problem is to develop a disaggregate production plan (Economic Lot Schedule) for five SKUs (white, blue, red, green, and pink) of a product to determine the optimal cycle length in order to minimize the total cost (or equivalent objective). The notations are presented in Table 1. However, you need to define new variables if required. Table 1: Notations Parameter/Variable j Indices of set of SKUs, j = {w,b,r.g.p) E D Demand of SKU j 4 Inventory on hand of SKU; P Available manhours for producing SKU; Total available manhours in cycle T P T Cycle length Note: The unit of measurement for D, 1, and P is manhours. Part A (8 marks) Demand and inventory on hand for five SKUs are presented in Table 2: Table 2: SKU's demand and inventory on hand for Part A White Blue Red Green Pink Dj 300 900 600 700 500 200 500 500 300 100 Given that the demands are deterministic and in manhours, and the available manhours (P,) for a cycle is 3000, i. ii. determine the sequence of producing the SKUs and show it in a simple graph. develop a linear programming model (in MS Word) and then solve it in Excel. explain the findings in details (MS Word) iii. iv. develop a table in which inventory position of all SKUs is presented for periods of switching the production for each SKU (MS Word and MS Excel). For inventory positions, round to the nearest integer and compute the sum of inventory on hand for each period. V. Is maximization of T in conflict with the JIT paradigm where we try to achieve the minimum manufacturing cycle time?

Step by Step Solution

3.55 Rating (166 Votes )

There are 3 Steps involved in it

Renovas problem is to develop a disaggregate productio... View full answer

Get step-by-step solutions from verified subject matter experts