Question: Statistical Process Control a . Twelve samples, each containing five parts, were taken from a process that produces steel rods. The length of each rod

Statistical Process Control

a Twelve samples, each containing five parts, were taken from a process that produces steel rods. The length of each rod in the samples was determined. The results were tabulated and sample means and ranges were computed. The results were:

tableSAMPLFSAMPLE MEAN nRALICE in

a Determine the upper and lower control limits and the overall means for charts and Rcharts.

b Draw the charts and plot the values of the sample means and ranges.

c Do the data indicate a process that is in control? b One of New England Air's top competitive priorities is ontime arrivals. Quality VP Clair

Bond decided to person ally monitor New England Air's performance. Each week for the

past weeks, Bond checked a random sample of flight arrivals for ontime

performance. The table that follows contains the number of flights that did not meet

New England Air's definition of on time":

a Using a confidence level, plot the overall percentage of late flights and

the upper and lower control limits on a control chart.

b Assume that the airline industry's upper and lower control limits for flights that are

not on time are and respectively. Draw them on your control chart.

c The manager of an organic yogurt processing plant

desires a quality specification with a mean of ounces, an upper

specification limit of and a lower specification limit of

The process has a mean of ounces and a standard deviation of

ource. Determine the Cpk of the process. Complete the questions listed below and submit electronically in the drop box.

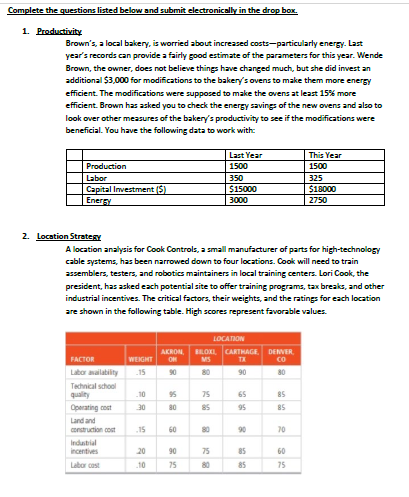

Productivity

Brown's, a local bakery, is worried about increased costsparticularly energy. Last

year's records can provide a fairly good estimate of the parameters for this year. Wende

Brown, the owner, does not believe things have changed much, but she did invest an

additional $ for modifications to the bakery's ovens to make them more energy

efficient. The modifications were supposed to make the ovens at least more

efficient. Brown has asked you to check the energy savings of the new ovens and also to

look over other measures of the bakery's productivity to see if the modifications were

beneficial. You have the following data to work with:

Location Strategy

A location analysis for Cook Controls, a small manufacturer of parts for hightechnology

cable systems, has been narrowed down to four locations. Cook will need to train

assemblers, testers, and robotics maintainers in local training centers. Lori Cook, the

president, has asked each potential site to offer training programs, tax breaks, and other

industrial incentives. The critical factors, their weights, and the ratings for each location

are shown in the following table. High scores represent favorable values.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock