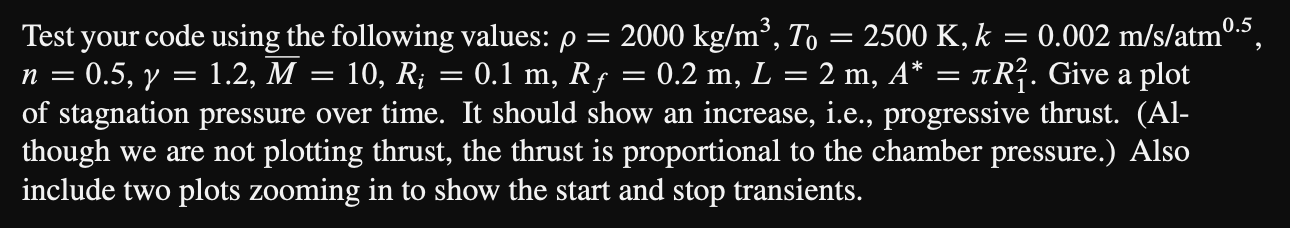

Question: = Test your code using the following values: p = 2000 kg/m, To = 2500 K, k = 0.002 m/s/atm n = 0.5, y:

= Test your code using the following values: p = 2000 kg/m, To = 2500 K, k = 0.002 m/s/atm n = 0.5, y: 1.2, M = 10, R = 0.1 m, R = 0.2 m, L = 2 m, A* = R. Give a plot of stagnation pressure over time. It should show an increase, i.e., progressive thrust. (Al- though we are not plotting thrust, the thrust is proportional to the chamber pressure.) Also include two plots zooming in to show the start and stop transients. 0.5 write Matlab code to simulate the firing of a solid rocket motor with a single cylindrical grain with a circular perforation. In such a motor, the radius of the perforation (the hole in the propellant grain) increases, so that the wetted perimeter, the mass flow, the chamber pressure, and the thrust all increase with time. This is called a progressive burn. Your code should use the Matlab function ode 45 to integrate the equations of change for two state variables: the perforation radius r(t) and the chamber pressure Po(t). These equa- tions are dr dt where k is the burn rate constant and n is the pressure exponent, and dPo dt = mg = kpn, RTO V Here R is the gas constant, given by R = R/M, where R = 8314 J/(kmol K) is the uni- versal gas constant and M is the average molecular weight of the exhaust gas; To is the flame temperature (this will be given; it depends on the solid chemistry); V = rL is the chamber volume, with L the length of the motor; mg and m, are the rates of gas generation and gas leaving the nozzle, respectively. The gas generation rate is m = A* = -(g mn). dr dt -2rLp, where p is the propellant density. The rate of gas leaving the nozzle is (assuming ideal gas flow) 2 VRTO (1+1) where A* is the sonic (throat) area and y is the specific heat ratio. 2(7-1) Your function should start out like function [t, P0] = solidSim ( rho, TO, k, n, gamma, Mbar, Ri, Rf, L, Astar ) which will compute two arrays: the time and the chamber pressure. (Here Ri is the initial value of the perforation radius r, and Rf is the burnout value, which is the same as the inner radius of the motor wall.) Your code should set the burn rate to zero when the radius reaches the burnout value, but continue the integration after burnout until the chamber pressure de- creases to atmospheric pressure (1 atm = 1.01 10 Pa).

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts