Question: The DC has 5 packing work stations and sufficient boxes, packaging material, etc. The average processing time (s = seconds) for the packaging process is

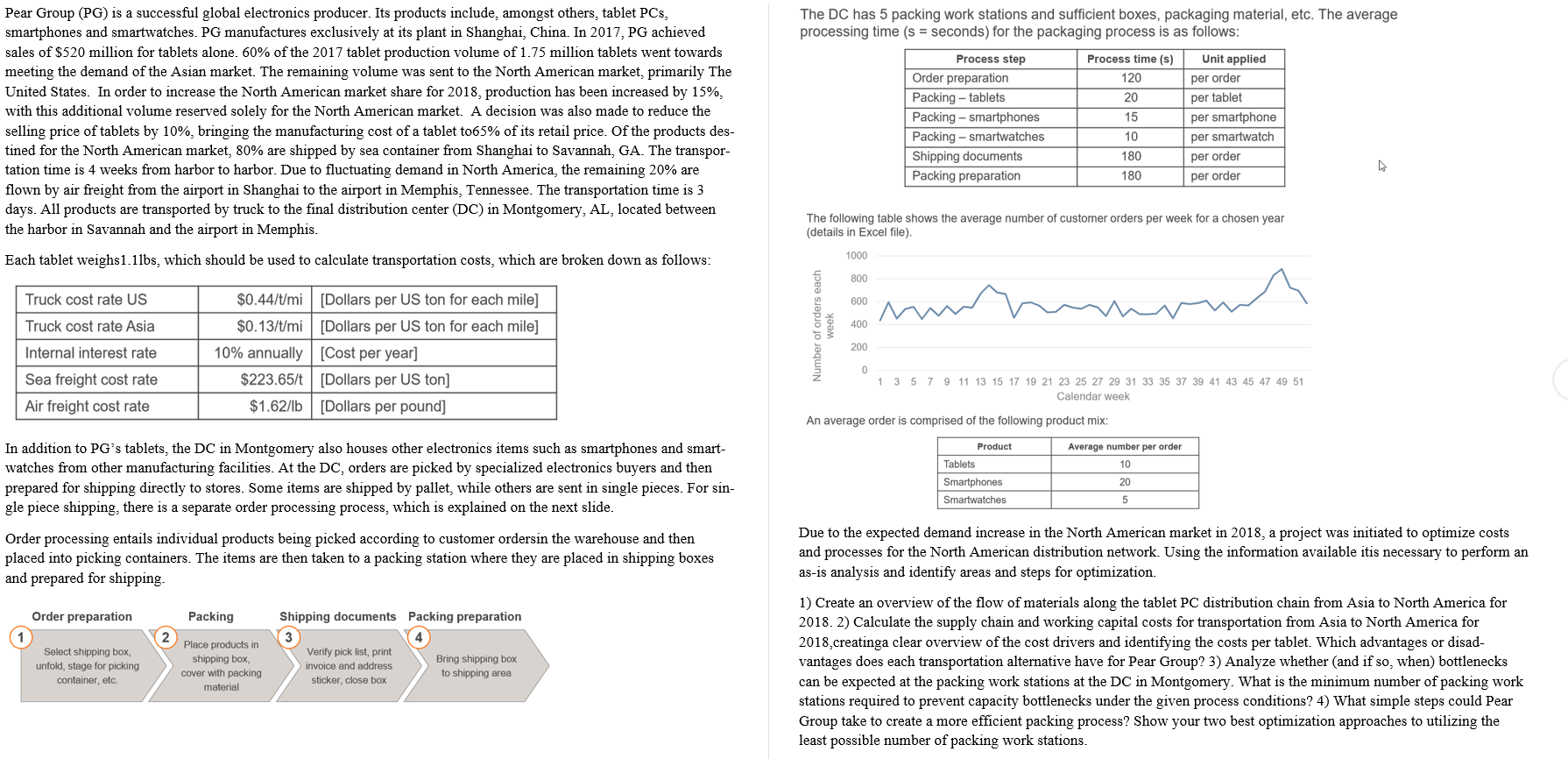

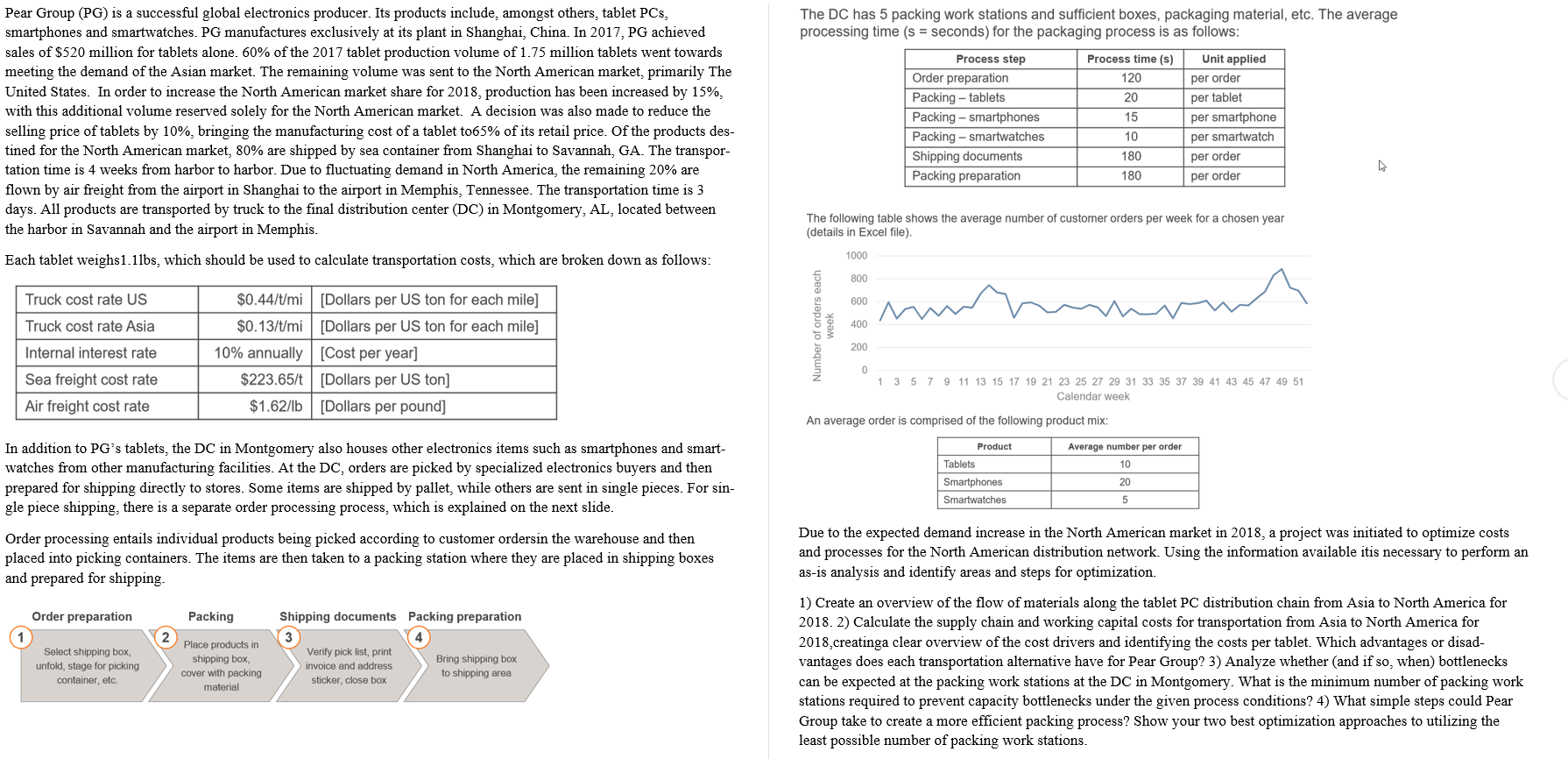

The DC has 5 packing work stations and sufficient boxes, packaging material, etc. The average processing time (s = seconds) for the packaging process is as follows: Pear Group (PG) is a successful global electronics producer. Its products include, amongst others, tablet PCs, smartphones and smartwatches. PG manufactures exclusively at its plant in Shanghai, China. In 2017, PG achieved sales of $520 million for tablets alone. 60% of the 2017 tablet production volume of 1.75 million tablets went towards meeting the demand of the Asian market. The remaining volume was sent to the North American market, primarily The United States. In order to increase the North American market share for 2018, production has been increased by 15%, with this additional volume reserved solely for the North American market. A decision was also made to reduce the selling price of tablets by 10%, bringing the manufacturing cost of a tablet to65% of its retail price. Of the products des- tined for the North American market, 80% are shipped by sea container from Shanghai to Savannah, GA. The transpor- tation time is 4 weeks from harbor to harbor. Due to fluctuating demand in North America, the remaining 20% are flown by air freight from the airport in Shanghai to the airport in Memphis, Tennessee. The transportation time is 3 days. All products are transported by truck to the final distribution center (DC) in Montgomery, AL, located between the harbor in Savannah and the airport in Memphis. Process step Order preparation Packing - tablets Packing - smartphones Packing - smartwatches Shipping documents Packing preparation Process time (s) 120 20 15 10 180 180 Unit applied per order per tablet per smartphone per smartwatch per order per order The following table shows the average number of customer orders per week for a chosen year (details in Excel file). Each tablet weighs1.1lbs, which should be used to calculate transportation costs, which are broken down as follows: 1000 Truck cost rate US Truck cost rate Asia Internal interest rate Sea freight cost rate Air freight cost rate $0.44/t/mi[Dollars per US ton for each mile) $0.13/t/mi[Dollars per US ton for each mile) 10% annually (Cost per year] $223.65/t [Dollars per US ton] $1.62/lb [Dollars per pound] Number of orders each week 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 51 Calendar week An average order is comprised of the following product mix: Product Average number per order Tablets 10 In addition to PG's tablets, the DC in Montgomery also houses other electronics items such as smartphones and smart- watches from other manufacturing facilities. At the DC, orders are picked by specialized electronics buyers and then prepared for shipping directly to stores. Some items are shipped by pallet, while others are sent in single pieces. For sin- gle piece shipping, there is a separate order processing process, which is explained on the next slide. Smartphones Smartwatches 20 5 Order processing entails individual products being picked according to customer ordersin the warehouse and then placed into picking containers. The items are then taken to a packing station where they are placed in shipping boxes and prepared for shipping. Due to the expected demand increase in the North American market in 2018, a project was initiated to optimize costs and processes for the North American distribution network. Using the information available itis necessary to perform an as-is analysis and identify areas and steps for optimization. Order preparation Packing Shipping documents Packing preparation Select shipping box, unfold, stage for picking container, etc. Place products in shipping box, cover with packing material Verify pick list, print invoice and address sticker, close box Bring shipping box to shipping area 1) Create an overview of the flow of materials along the tablet PC distribution chain from Asia to North America for 2018. 2) Calculate the supply chain and working capital costs for transportation from Asia to North America for 2018,creatinga clear overview of the cost drivers and identifying the costs per tablet. Which advantages or disad- vantages does each transportation alternative have for Pear Group? 3) Analyze whether (and if so, when) bottlenecks can be expected at the packing work stations at the DC in Montgomery. What is the minimum number of packing work stations required to prevent capacity bottlenecks under the given process conditions? 4) What simple steps could Pear Group take to create a more efficient packing process? Show your two best optimization approaches to utilizing the least possible number of packing work stations. The DC has 5 packing work stations and sufficient boxes, packaging material, etc. The average processing time (s = seconds) for the packaging process is as follows: Pear Group (PG) is a successful global electronics producer. Its products include, amongst others, tablet PCs, smartphones and smartwatches. PG manufactures exclusively at its plant in Shanghai, China. In 2017, PG achieved sales of $520 million for tablets alone. 60% of the 2017 tablet production volume of 1.75 million tablets went towards meeting the demand of the Asian market. The remaining volume was sent to the North American market, primarily The United States. In order to increase the North American market share for 2018, production has been increased by 15%, with this additional volume reserved solely for the North American market. A decision was also made to reduce the selling price of tablets by 10%, bringing the manufacturing cost of a tablet to65% of its retail price. Of the products des- tined for the North American market, 80% are shipped by sea container from Shanghai to Savannah, GA. The transpor- tation time is 4 weeks from harbor to harbor. Due to fluctuating demand in North America, the remaining 20% are flown by air freight from the airport in Shanghai to the airport in Memphis, Tennessee. The transportation time is 3 days. All products are transported by truck to the final distribution center (DC) in Montgomery, AL, located between the harbor in Savannah and the airport in Memphis. Process step Order preparation Packing - tablets Packing - smartphones Packing - smartwatches Shipping documents Packing preparation Process time (s) 120 20 15 10 180 180 Unit applied per order per tablet per smartphone per smartwatch per order per order The following table shows the average number of customer orders per week for a chosen year (details in Excel file). Each tablet weighs1.1lbs, which should be used to calculate transportation costs, which are broken down as follows: 1000 Truck cost rate US Truck cost rate Asia Internal interest rate Sea freight cost rate Air freight cost rate $0.44/t/mi[Dollars per US ton for each mile) $0.13/t/mi[Dollars per US ton for each mile) 10% annually (Cost per year] $223.65/t [Dollars per US ton] $1.62/lb [Dollars per pound] Number of orders each week 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 51 Calendar week An average order is comprised of the following product mix: Product Average number per order Tablets 10 In addition to PG's tablets, the DC in Montgomery also houses other electronics items such as smartphones and smart- watches from other manufacturing facilities. At the DC, orders are picked by specialized electronics buyers and then prepared for shipping directly to stores. Some items are shipped by pallet, while others are sent in single pieces. For sin- gle piece shipping, there is a separate order processing process, which is explained on the next slide. Smartphones Smartwatches 20 5 Order processing entails individual products being picked according to customer ordersin the warehouse and then placed into picking containers. The items are then taken to a packing station where they are placed in shipping boxes and prepared for shipping. Due to the expected demand increase in the North American market in 2018, a project was initiated to optimize costs and processes for the North American distribution network. Using the information available itis necessary to perform an as-is analysis and identify areas and steps for optimization. Order preparation Packing Shipping documents Packing preparation Select shipping box, unfold, stage for picking container, etc. Place products in shipping box, cover with packing material Verify pick list, print invoice and address sticker, close box Bring shipping box to shipping area 1) Create an overview of the flow of materials along the tablet PC distribution chain from Asia to North America for 2018. 2) Calculate the supply chain and working capital costs for transportation from Asia to North America for 2018,creatinga clear overview of the cost drivers and identifying the costs per tablet. Which advantages or disad- vantages does each transportation alternative have for Pear Group? 3) Analyze whether (and if so, when) bottlenecks can be expected at the packing work stations at the DC in Montgomery. What is the minimum number of packing work stations required to prevent capacity bottlenecks under the given process conditions? 4) What simple steps could Pear Group take to create a more efficient packing process? Show your two best optimization approaches to utilizing the least possible number of packing work stations