Question: The engineering team re-designed the valve and changed the outlet strut design to a mono-strut arrangement, which was machined from one piece rather than

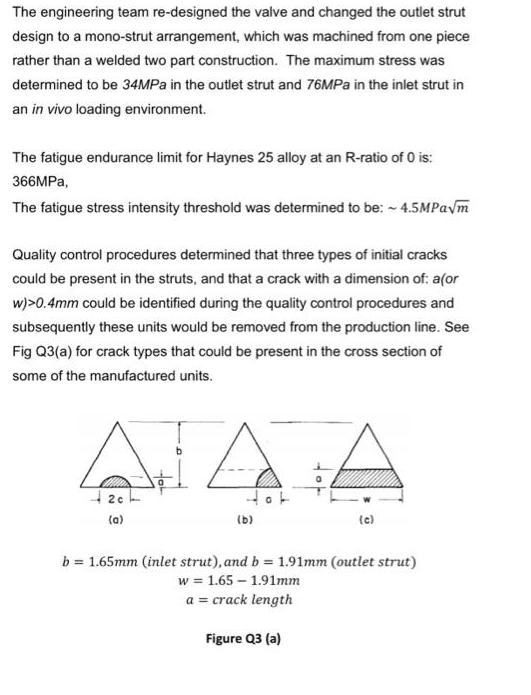

The engineering team re-designed the valve and changed the outlet strut design to a mono-strut arrangement, which was machined from one piece rather than a welded two part construction. The maximum stress was determined to be 34MPa in the outlet strut and 76MPa in the inlet strut in an in vivo loading environment. The fatigue endurance limit for Haynes 25 alloy at an R-ratio of 0 is: 366MPa, The fatigue stress intensity threshold was determined to be: ~4.5MPam Quality control procedures determined that three types of initial cracks could be present in the struts, and that a crack with a dimension of: a(or w) >0.4mm could be identified during the quality control procedures and subsequently these units would be removed from the production line. See Fig Q3(a) for crack types that could be present in the cross section of some of the manufactured units. ATA A (c) (a) (b) b = 1.65mm (inlet strut), and b = 1.91mm (outlet strut) w = 1.65-1.91mm a = crack length Figure Q3 (a)

Step by Step Solution

3.49 Rating (159 Votes )

There are 3 Steps involved in it

The redesigned valve and fatigue analysis of the Haynes 25 struts Based on the details youve given h... View full answer

Get step-by-step solutions from verified subject matter experts