Question: The first screenshot is the question, the second is additional info. Content Bb Microsoft Word - 2017 Sprix Bb Microsoft Word - 2021 Fall X

The first screenshot is the question, the second is additional info.

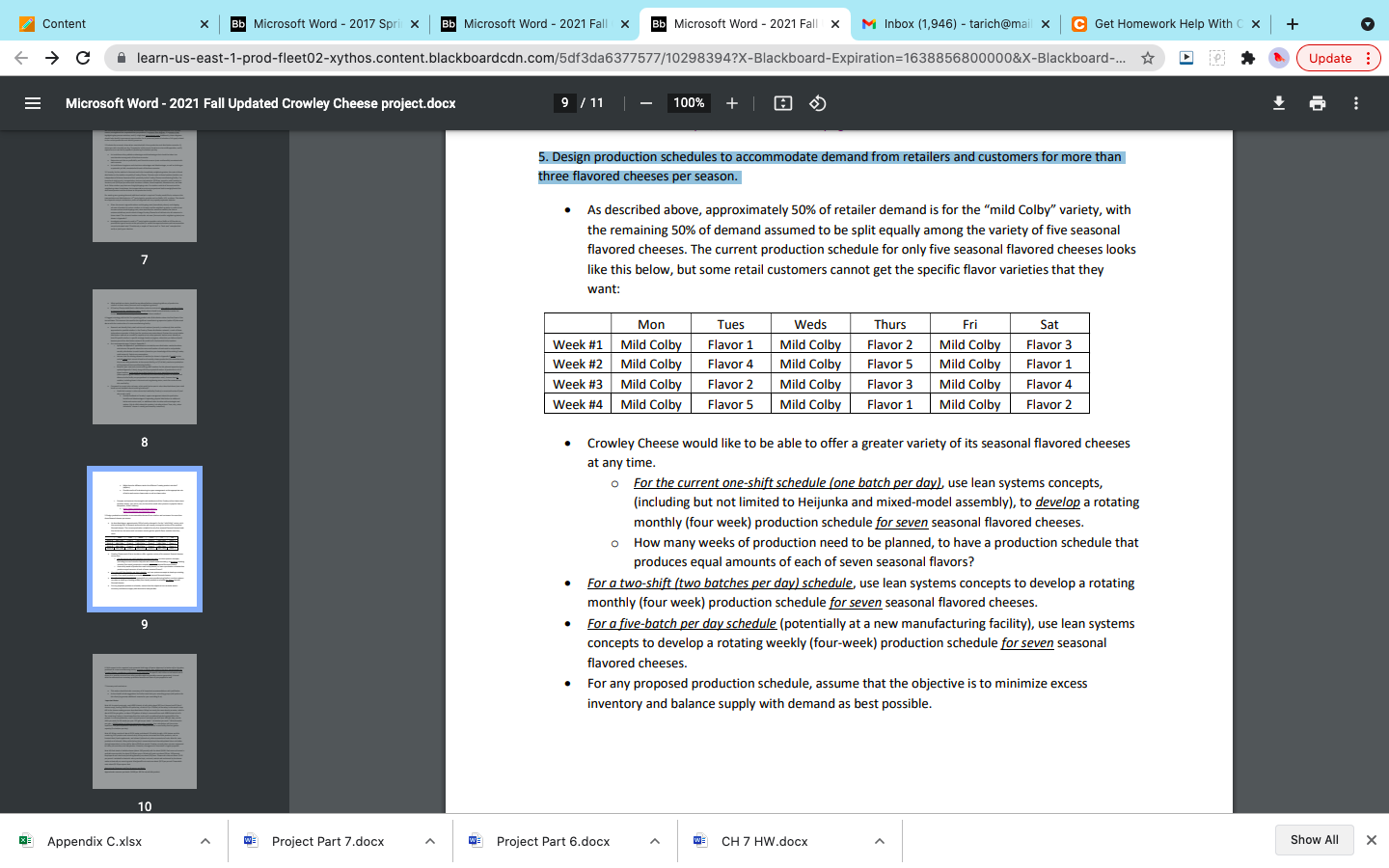

Content Bb Microsoft Word - 2017 Sprix Bb Microsoft Word - 2021 Fall X Microsoft Word - 2021 Fall X M Inbox (1,946) - tarich@mai x C Get Homework Help With + . learn-us-east-1-prod-fleet02-xythos.content.blackboardcdn.com/5df3da6377577/10298394?X-Blackboard-Expiration=1638856800000&X-Blackboard-... Update : Microsoft Word - 2021 Fall Updated Crowley Cheese project.docx 9 / 11 100% + @ 5. Design production schedules to accommodate demand from retailers and customers for more than three flavored cheeses per season. As described above, approximately 50% of retailer demand is for the "mild Colby" variety, with the remaining 50% of demand assumed to be split equally among the variety of five seasonal flavored cheeses. The current production schedule for only five seasonal flavored cheeses looks like this below, but some retail customers cannot get the specific flavor varieties that they want: 7 Week #1 Week #2 Week #3 Week #4 Mon Mild Colby Mild Colby Mild Colby Mild Colby Tues Flavor 1 Flavor 4 Flavor 2 Flavor 5 Weds Mild Colby Mild Colby Mild Colby Mild Colby Thurs Flavor 2 Flavor 5 Flavor 3 Flavor 1 Fri Mild Colby Mild Colby Mild Colby Mild Colby Sat Flavor 3 Flavor 1 Flavor 4 Flavor 2 8 o Crowley Cheese would like to be able to offer a greater variety of its seasonal flavored cheeses at any time. For the current one-shift schedule (one batch per day), use lean systems concepts, (including but not limited to Heijunka and mixed-model assembly), to develop a rotating monthly (four week) production schedule for seven seasonal flavored cheeses. How many weeks of production need to be planned, to have a production schedule that produces equal amounts of each of seven seasonal flavors? For a two-shift (two batches per day) schedule, use lean systems concepts to develop a rotating monthly (four week) production schedule for seven seasonal flavored cheeses. For a five-batch per day schedule (potentially at a new manufacturing facility), use lean systems concepts to develop a rotating weekly (four-week) production schedule for seven seasonal flavored cheeses. For any proposed production schedule, assume that the objective is to minimize excess inventory and balance supply with demand as best possible. 9 10 Appendix C.xlsx w Project Part 7.docx w Project Part 6.docx CH 7 HW.docx Show All Content Bb Microsoft Word - 2017 Sprix Bb Microsoft Word - 2021 Fall X Microsoft Word - 2021 Fall X M Inbox (1,946) - tarich@mai x C Get Homework Help With + . learn-us-east-1-prod-fleet02-xythos.content.blackboardcdn.com/5df3da6377577/10298394?X-Blackboard-Expiration=1638856800000&X-Blackb... Update : Microsoft Word - 2021 Fall Updated Crowley Cheese project.docx 2 / 11 91% + : Case Notes from another analysis team Details of the current production process: 1 Currently, the company operates one shift per day, six days per week. This current level of production makes one batch of product per shift, with four employees providing direct labor. In one daily batch, 4000 pounds of milk is transformed into about 400 pounds of cheese (minus scrap, about 365 lbs sellable), which is sold to various retailers for a total wholesale price of about $4106 per batch (approx. $11.25 per pound, wholesale). During any one season of the year, Crowley produces their primary product (mild Colby), and an additional five seasonal varieties (six varieties total, per season). The seasonal varieties vary throughout the year. For six production batches per week, three batches are dedicated to producing the primary product (mild Colby), which constitutes 50% of the demand for one week. The remaining three batches of production are dedicated to one of the five other seasonal products (one unique seasonal product per batch or per shift). On average, demand for the five seasonal varieties is split evenly among the varieties available. Customers and retailers have requested a greater variety of products throughout the year. Current annual cheese-related revenue for Crowley is estimated at about: (48 weeks/year) * six batches/week) * ($4106 revenue/ per batch) = $1,182,600 per year gross revenues. 2 The following describes the production process for a daily batch of cheese. Some cheese-making videos exist on the internet, and could be helpful in understanding the processes. Please review this video for a couple of the visual details related to the detailed written notes below: https://www.youtube.com/watch?v=69854FqSMr8 If you rent or buy it from Amazon.com, the Crowley Cheese episode of Dirty Jobs with Mike Rowe is very instructional. Season 1, Episode 12, at about 13:00 min into the episode. It is a good view of what your other team members witnessed, when they visited Crowley Cheese. Data and analysis from their site tour is below. The Process: 3 1. At the beginning of each shift, all four workers thoroughly clean the steam-table vat, the curd sink, and various fixtures with a chlorine solution: (requires 60 minutes). This requires all four employees. After completion of cleaning, three of the employees attend to finishing the previous day's batch of cheese (see notes on the other process steps below, (e.g steps #4 and #19, 20, 21). 2. Next, the lead cheese artisan (Ken) pumps/pours about 4000 pounds of raw whole milk into the steam-table vat from the dairy tank. Currently, Crowley receives one 4000 pound delivery per day. The dairy tank can be unloaded in about 15 minutes to fill the steam table. One gallon of milk weighs about 8.6 lbs, so 4000 pounds of raw whole milk is approximately 465.1 gallons. Content Bb Microsoft Word - 2017 Sprix Bb Microsoft Word - 2021 Fall X Microsoft Word - 2021 Fall X M Inbox (1,946) - tarich@mai x C Get Homework Help With + . learn-us-east-1-prod-fleet02-xythos.content.blackboardcdn.com/5df3da6377577/10298394?X-Blackboard-Expiration=1638856800000&X-Blackboard-... Update : Microsoft Word - 2021 Fall Updated Crowley Cheese project.docx 9 / 11 100% + @ 5. Design production schedules to accommodate demand from retailers and customers for more than three flavored cheeses per season. As described above, approximately 50% of retailer demand is for the "mild Colby" variety, with the remaining 50% of demand assumed to be split equally among the variety of five seasonal flavored cheeses. The current production schedule for only five seasonal flavored cheeses looks like this below, but some retail customers cannot get the specific flavor varieties that they want: 7 Week #1 Week #2 Week #3 Week #4 Mon Mild Colby Mild Colby Mild Colby Mild Colby Tues Flavor 1 Flavor 4 Flavor 2 Flavor 5 Weds Mild Colby Mild Colby Mild Colby Mild Colby Thurs Flavor 2 Flavor 5 Flavor 3 Flavor 1 Fri Mild Colby Mild Colby Mild Colby Mild Colby Sat Flavor 3 Flavor 1 Flavor 4 Flavor 2 8 o Crowley Cheese would like to be able to offer a greater variety of its seasonal flavored cheeses at any time. For the current one-shift schedule (one batch per day), use lean systems concepts, (including but not limited to Heijunka and mixed-model assembly), to develop a rotating monthly (four week) production schedule for seven seasonal flavored cheeses. How many weeks of production need to be planned, to have a production schedule that produces equal amounts of each of seven seasonal flavors? For a two-shift (two batches per day) schedule, use lean systems concepts to develop a rotating monthly (four week) production schedule for seven seasonal flavored cheeses. For a five-batch per day schedule (potentially at a new manufacturing facility), use lean systems concepts to develop a rotating weekly (four-week) production schedule for seven seasonal flavored cheeses. For any proposed production schedule, assume that the objective is to minimize excess inventory and balance supply with demand as best possible. 9 10 Appendix C.xlsx w Project Part 7.docx w Project Part 6.docx CH 7 HW.docx Show All Content Bb Microsoft Word - 2017 Sprix Bb Microsoft Word - 2021 Fall X Microsoft Word - 2021 Fall X M Inbox (1,946) - tarich@mai x C Get Homework Help With + . learn-us-east-1-prod-fleet02-xythos.content.blackboardcdn.com/5df3da6377577/10298394?X-Blackboard-Expiration=1638856800000&X-Blackb... Update : Microsoft Word - 2021 Fall Updated Crowley Cheese project.docx 2 / 11 91% + : Case Notes from another analysis team Details of the current production process: 1 Currently, the company operates one shift per day, six days per week. This current level of production makes one batch of product per shift, with four employees providing direct labor. In one daily batch, 4000 pounds of milk is transformed into about 400 pounds of cheese (minus scrap, about 365 lbs sellable), which is sold to various retailers for a total wholesale price of about $4106 per batch (approx. $11.25 per pound, wholesale). During any one season of the year, Crowley produces their primary product (mild Colby), and an additional five seasonal varieties (six varieties total, per season). The seasonal varieties vary throughout the year. For six production batches per week, three batches are dedicated to producing the primary product (mild Colby), which constitutes 50% of the demand for one week. The remaining three batches of production are dedicated to one of the five other seasonal products (one unique seasonal product per batch or per shift). On average, demand for the five seasonal varieties is split evenly among the varieties available. Customers and retailers have requested a greater variety of products throughout the year. Current annual cheese-related revenue for Crowley is estimated at about: (48 weeks/year) * six batches/week) * ($4106 revenue/ per batch) = $1,182,600 per year gross revenues. 2 The following describes the production process for a daily batch of cheese. Some cheese-making videos exist on the internet, and could be helpful in understanding the processes. Please review this video for a couple of the visual details related to the detailed written notes below: https://www.youtube.com/watch?v=69854FqSMr8 If you rent or buy it from Amazon.com, the Crowley Cheese episode of Dirty Jobs with Mike Rowe is very instructional. Season 1, Episode 12, at about 13:00 min into the episode. It is a good view of what your other team members witnessed, when they visited Crowley Cheese. Data and analysis from their site tour is below. The Process: 3 1. At the beginning of each shift, all four workers thoroughly clean the steam-table vat, the curd sink, and various fixtures with a chlorine solution: (requires 60 minutes). This requires all four employees. After completion of cleaning, three of the employees attend to finishing the previous day's batch of cheese (see notes on the other process steps below, (e.g steps #4 and #19, 20, 21). 2. Next, the lead cheese artisan (Ken) pumps/pours about 4000 pounds of raw whole milk into the steam-table vat from the dairy tank. Currently, Crowley receives one 4000 pound delivery per day. The dairy tank can be unloaded in about 15 minutes to fill the steam table. One gallon of milk weighs about 8.6 lbs, so 4000 pounds of raw whole milk is approximately 465.1 gallonsStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock