Question: undefined A Vendor Selection Problem An electronic assembly plant uses a standard microchip at a uniform rate of 2,000 units per year. The firm's inventory

undefined

undefined

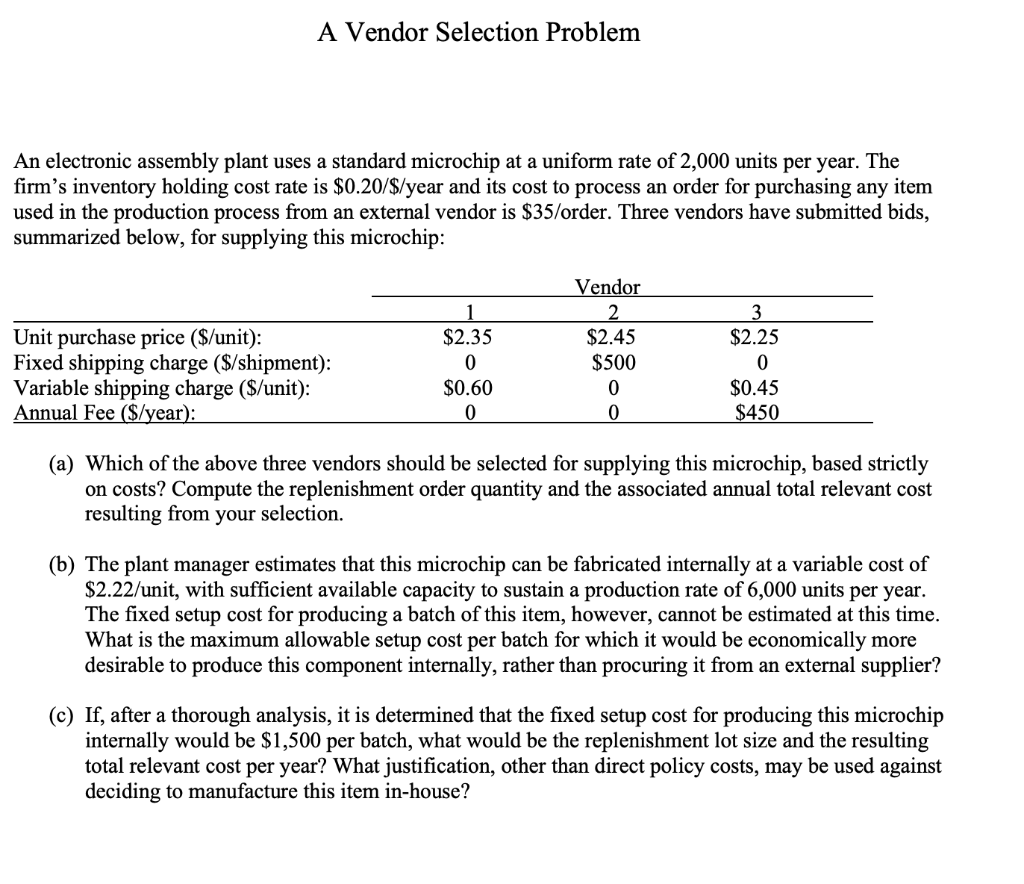

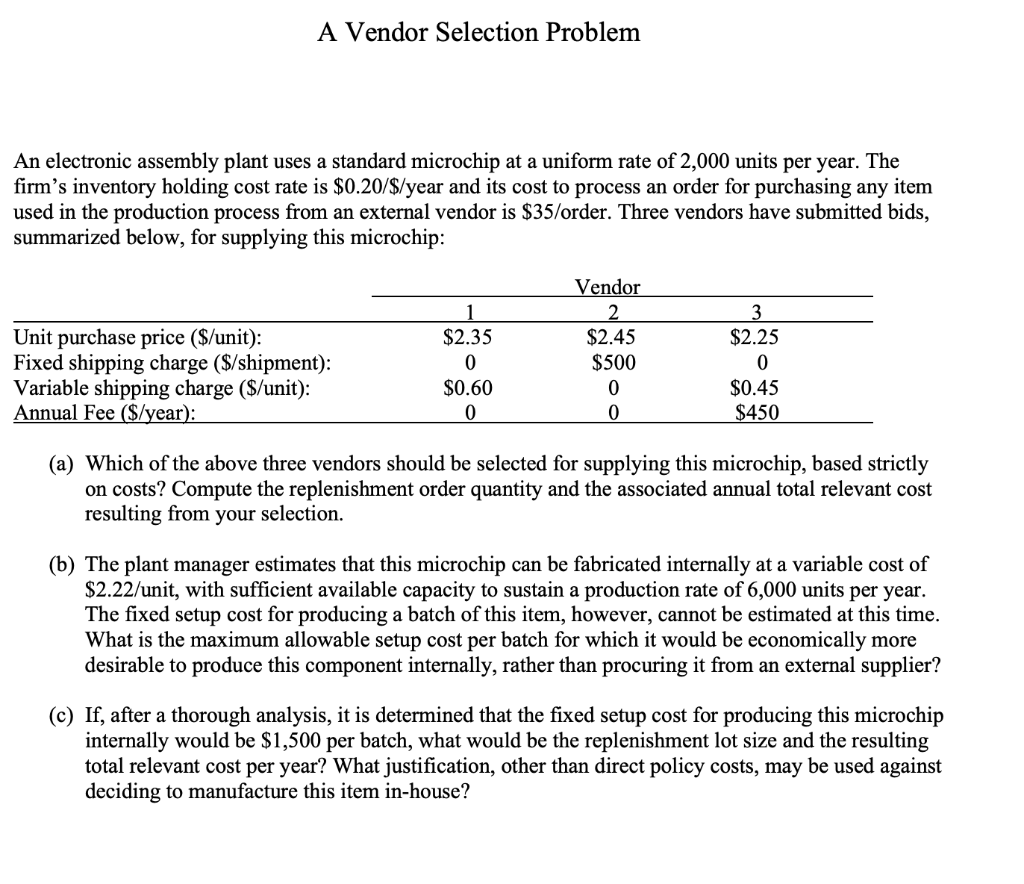

A Vendor Selection Problem An electronic assembly plant uses a standard microchip at a uniform rate of 2,000 units per year. The firm's inventory holding cost rate is $0.20/$/year and its cost to process an order for purchasing any item used in the production process from an external vendor is $35/order. Three vendors have submitted bids, summarized below, for supplying this microchip: Unit purchase price ($/unit): Fixed shipping charge ($/shipment): Variable shipping charge ($/unit): Annual Fee ($/year): 1 $2.35 0 $0.60 0 Vendor 2 $2.45 $500 0 0 3 $2.25 0 $0.45 $450 (a) Which of the above three vendors should be selected for supplying this microchip, based strictly on costs? Compute the replenishment order quantity and the associated annual total relevant cost resulting from your selection. (b) The plant manager estimates that this microchip can be fabricated internally at a variable cost of $2.22/unit, with sufficient available capacity to sustain a production rate of 6,000 units per year. The fixed setup cost for producing a batch of this item, however, cannot be estimated at this time. What is the maximum allowable setup cost per batch for which it would be economically more desirable to produce this component internally, rather than procuring it from an external supplier? (c) If, after a thorough analysis, it is determined that the fixed setup cost for producing this microchip internally would be $1,500 per batch, what would be the replenishment lot size and the resulting total relevant cost per year? What justification, other than direct policy costs, may be used against deciding to manufacture this item in-house? A Vendor Selection Problem An electronic assembly plant uses a standard microchip at a uniform rate of 2,000 units per year. The firm's inventory holding cost rate is $0.20/$/year and its cost to process an order for purchasing any item used in the production process from an external vendor is $35/order. Three vendors have submitted bids, summarized below, for supplying this microchip: Unit purchase price ($/unit): Fixed shipping charge ($/shipment): Variable shipping charge ($/unit): Annual Fee ($/year): 1 $2.35 0 $0.60 0 Vendor 2 $2.45 $500 0 0 3 $2.25 0 $0.45 $450 (a) Which of the above three vendors should be selected for supplying this microchip, based strictly on costs? Compute the replenishment order quantity and the associated annual total relevant cost resulting from your selection. (b) The plant manager estimates that this microchip can be fabricated internally at a variable cost of $2.22/unit, with sufficient available capacity to sustain a production rate of 6,000 units per year. The fixed setup cost for producing a batch of this item, however, cannot be estimated at this time. What is the maximum allowable setup cost per batch for which it would be economically more desirable to produce this component internally, rather than procuring it from an external supplier? (c) If, after a thorough analysis, it is determined that the fixed setup cost for producing this microchip internally would be $1,500 per batch, what would be the replenishment lot size and the resulting total relevant cost per year? What justification, other than direct policy costs, may be used against deciding to manufacture this item in-house

undefined

undefined