Question: use example 1 as Reference 1 of 2 Module 1: Material handling Module 1. Chapter 5 Textbook A)- Reading Assignment: Read Chapter 8 Note that,

use example 1 as Reference

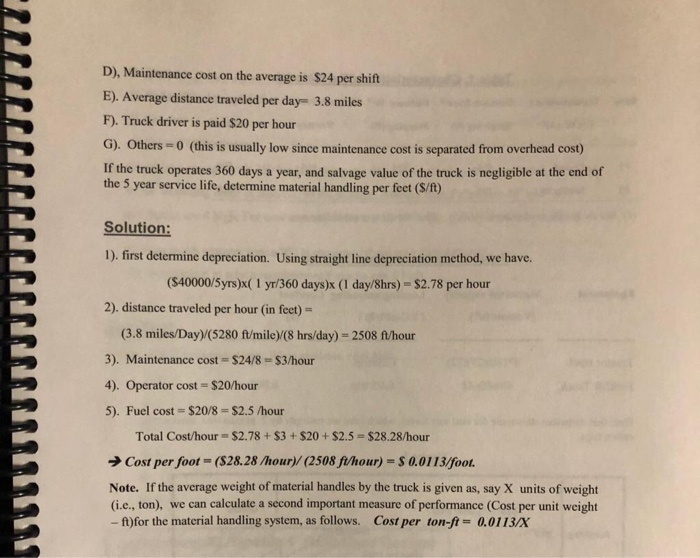

1 of 2 Module 1: Material handling Module 1. Chapter 5 Textbook A)- Reading Assignment: Read Chapter 8 Note that, a large part of chapter 8 contains material describing different types of material handling equipment. This material are intended to be used as a reference to be used in selecting material handling equipment. You need to review the material, to get familiar with different type of handling system available in the market. B)- homework Assignment: Set #1. Unit Load Design (Due. 01/26/2016) Assignment 1: In order to realize the impact of unit load on the efficiency of operations, costs and other metrics, use the example 1 as the basis and answer the following questions. Assuming we can not load a pallet higher than 3' (The 3' includes the 6" height of the pallet), determine: 1. Space Utilization values for Carton, Pallet, and Truck, using the following (Modified) information The dimensions of the carton used is 12x18x12 We use a larger pallet with dimensions 48x48" (Height the same as before) 2. Cost of storage rental, assuming we store 2 weeks of inventory on a continuous basis and pay $3.5/yrd per month. Do this for both cases (original case in example 1 and the modified case discussed in this assignment) and calculate change on storage cost (in %) because of using different sizes of unit loads. Note: you have to leave 2"clearance between stacks). Note that you need to determine cost only for the Ir you need not for the whole warehouse. 3. For the above system (Figure 1) determine the R1, R2 R3. and R4 Ratios Assignment 2 The ABC Logistics Corp. Uses a nesting container (See Fig 1)for transporting some special Chemical from Chicago to Texas. The dimensions of the container are EXAMPLE 1 A forklift truck is used to Transport units of loads (Pallets of load .48" x 40" x 6", in dimensions) from receiving dock /to storage area and storage area to shipping docks. The following cost data is collected by the facility engineer A). Initial cost - 540000 B). Fuel cost - $20 per shift (8 Hours). C). Product life = 5 years, D), Maintenance cost on the average is $24 per shift E). Average distance traveled per day= 3.8 miles F). Truck driver is paid $20 per hour G). Others 0 (this is usually low since maintenance cost is separated from overhead cost) If the truck operates 360 days a year, and salvage value of the truck is negligible at the end of the 5 year service life, determine material handling per feet (S/ft) Solution: 1). first determine depreciation. Using straight line depreciation method, we have. (540000/5yrs)x( 1 yr/360 days)x (1 day/8hrs) - $2.78 per hour 2). distance traveled per hour (in feet) = (3.8 miles/Day)/(5280 ft/mile)/(8 hrs/day) - 2508 ft/hour 3). Maintenance cost = $24/8 $3/hour 4). Operator cost = $20/hour 5). Fuel cost = $20/8 = $2.5 /hour Total Cost/hour $2.78 + $3 + $20+ $2.5 = $28.28/hour Cost per foot = ($28.28 /hour)/(2508 ft/hour) = $ 0.0113/foot. Note. If the average weight of material handles by the truck is given as, say X units of weight (i.e., ton), we can calculate a second important measure of performance (Cost per unit weight - ft)for the material handling system, as follows. Cost per ton-ft = 0.0113/X