Question: You are analyzing a workstation with one worker and multiple identical machines producing a single part type. The machine operation of a part takes 55

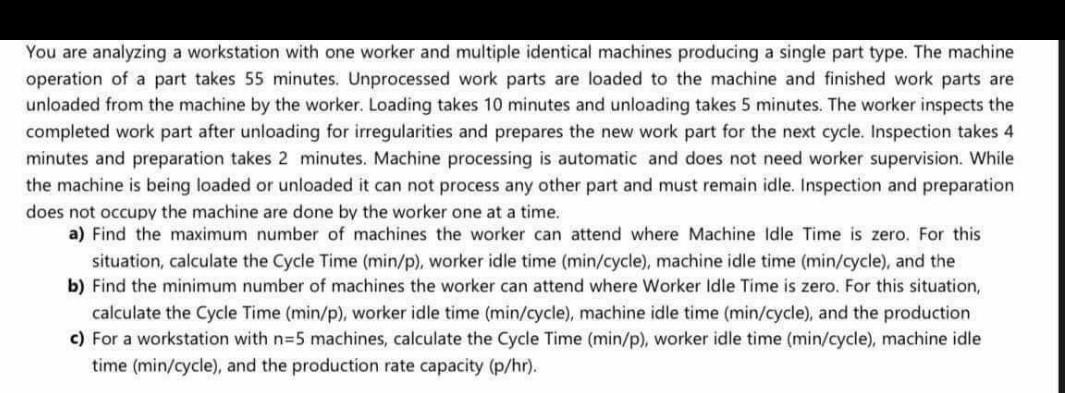

You are analyzing a workstation with one worker and multiple identical machines producing a single part type. The machine operation of a part takes 55 minutes. Unprocessed work parts are loaded to the machine and finished work parts are unloaded from the machine by the worker. Loading takes 10 minutes and unloading takes 5 minutes. The worker inspects the completed work part after unloading for irregularities and prepares the new work part for the next cycle. Inspection takes 4 minutes and preparation takes 2 minutes. Machine processing is automatic and does not need worker supervision. While the machine is being loaded or unloaded it can not process any other part and must remain idle. Inspection and preparation does not occupy the machine are done by the worker one at a time. a) Find the maximum number of machines the worker can attend where Machine Idle Time is zero. For this situation, calculate the Cycle Time (min/p), worker idle time (min/cycle), machine idle time (min/cycle), and the b) Find the minimum number of machines the worker can attend where Worker Idle Time is zero. For this situation, calculate the Cycle Time (min/p), worker idle time (min/cycle), machine idle time (min/cycle), and the production c) For a workstation with n=5 machines, calculate the Cycle Time (min/p), worker idle time (min/cycle), machine idle time (min/cycle), and the production rate capacity (p/hr)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts