A standard 0.505-in.-diameter tensile bar was machined to a 2.00-in.-gage length from a copper-nickel alloy and the

Question:

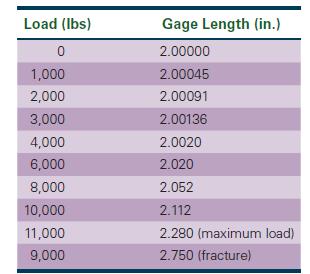

A standard 0.505-in.-diameter tensile bar was machined to a 2.00-in.-gage length from a copper-nickel alloy and the following data were collected:

After fracture, the gage length was 2.75 in. and the diameter was 0.365 in. Plot the engineering stress strain curve and calculate

(a) The 0.2% offset yield strength;

(b) The tensile strength;

(c) The modulus of elasticity;

(d) The % elongation;

(e) The % reduction in area;

(f) The engineering stress at fracture;

(g) The true stress at necking; and

(h) The modulus of resilience.

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

The Science And Engineering Of Materials

ISBN: 9781305076761

7th Edition

Authors: Donald R. Askeland, Wendelin J. Wright

Question Posted: