Consider the recuperator of the supercritical CO 2 cycle power plant of Exercise 7.19 Assume that the

Question:

Consider the recuperator of the supercritical CO2 cycle power plant of Exercise 7.19 Assume that the energy rejected to the environment from the surface of the insulating material covering the recuperator is negligible, and that the environment is at T0 = 308 K and P0 = 1 atm. Calculate the change in flow exergy rate of each CO2 stream, the rate of exergy loss in the heat exchanger, and its exergetic efficiency.

Data From Exercise 7.19

Consider a closed recuperative Brayton cycle turbine power plant employing supercritical CO2?as the working fluid. The working fluid at the compressor inlet is at T = 32?C and P = 7.7 MPa. CO2 pressure in the heater is 20 MPa and the turbine inlet temperature is 550?C. The regenerator effectiveness is 0.95, see Exercise 7.15. The isentropic efficiency of the compressor is 0.89 and that of the turbine is 0.90. Calculate the mass flow rate of CO2 if the power plant must deliver 50 MW, and its conversion efficiency. All pressure and thermal losses can be assumed as zero.

Data From Exercise 7.15

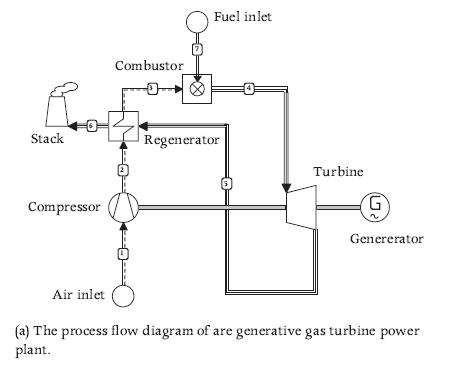

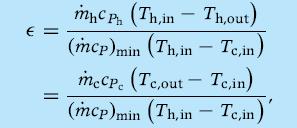

In the regenerative gas turbine power plant whose process flow diagram is shown in Figure 7.27a, the mass flow of air entering the compressor at 1 bar and 25?C is 17.9 kg/s. The pressure ratio of the compressor is 9.9. The regenerator effectiveness is 0.9. The effectiveness of a counter flow heat exchanger is defined as

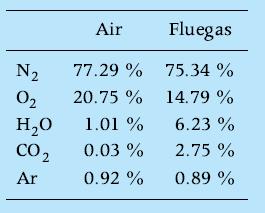

where subscripts h and c stand for the hot and the cold stream, respectively, and (m?cP)min is the smallest heat capacitance of these two streams. The isentropic efficiency of the compressor is 0.89 and that of the turbine is 0.92. The turbine inlet temperature is 1160?C. The mass flow of fuel entering the combustor is 0.36 kg/s and the lower heating value of the fuel is 38 MJ/kg (Dutch Slochteren natural gas). The air and exhaust gas composition are2

Assume that there are no pressure or thermal losses anywhere in the system and that no air is spilled from the compressor for turbine blade cooling. Determine the net mechanical power output in kW and the conversion efficiency of the system.

Step by Step Answer:

Thermodynamics Fundamentals And Engineering Applications

ISBN: 9780521862738

1st Edition

Authors: William C. Reynolds, Piero Colonna