Question: 9 . 2 Allowable Stress Design To the nearest 1 1 6 i n , determine the required thickness of member B and the diameter

Allowable Stress Design

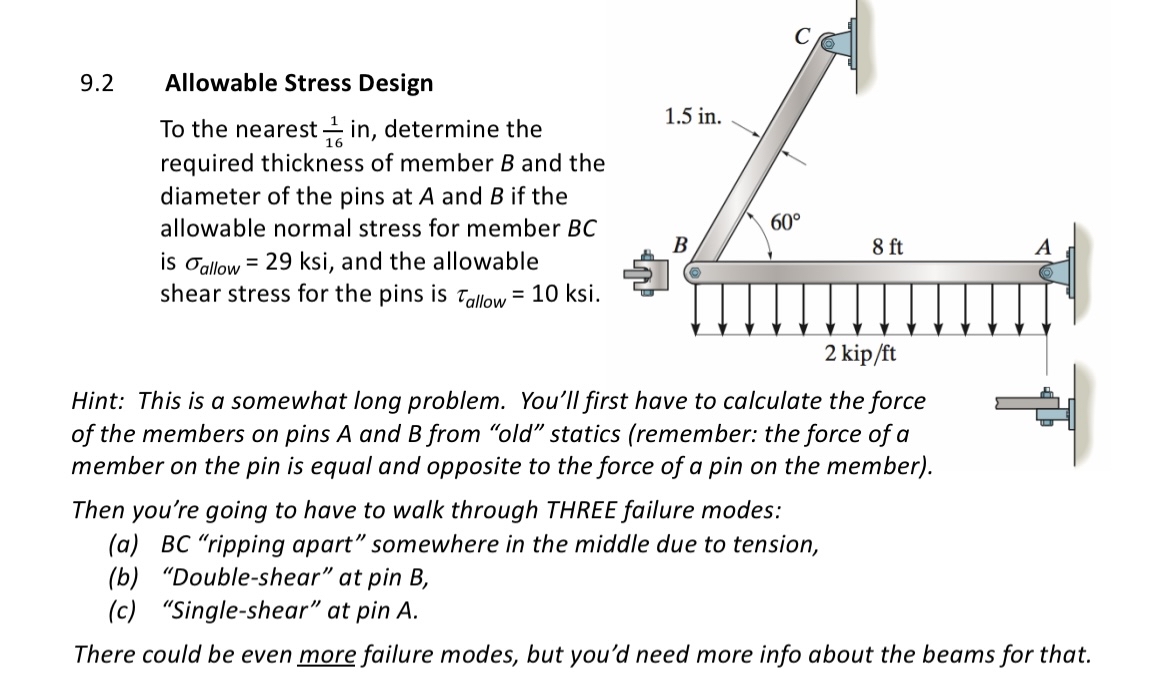

To the nearest determine the required thickness of member and the diameter of the pins at A and if the allowable normal stress for member is ksi, and the allowable shear stress for the pins is ksi.

Hint: This is a somewhat long problem. You'll first have to calculate the force of the members on pins A and B from "old" statics remember: the force of a member on the pin is equal and opposite to the force of a pin on the member

Then you're going to have to walk through THREE failure modes:

a BC "ripping apart" somewhere in the middle due to tension,

b "Doubleshear" at pin B

c "Singleshear" at pin A

There could be even more failure modes, but you'd need more info about the beams for that.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock