Question: Consider a line with two workstations. Workstation 1 has a process time of 10 minutes and SCV off .2. Workstation 2 is prone to rework.

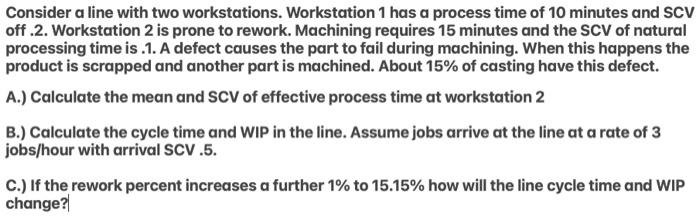

Consider a line with two workstations. Workstation 1 has a process time of 10 minutes and SCV off .2. Workstation 2 is prone to rework. Machining requires 15 minutes and the SCV of natural processing time is .1. A defect causes the part to fail during machining. When this happens the product is scrapped and another part is machined. About 15% of casting have this defect. A.) Calculate the mean and SCV of effective process time at workstation 2 B.) Calculate the cycle time and WIP in the line. Assume jobs arrive at the line at a rate of 3 jobs/hour with arrival SCV .5. C.) If the rework percent increases a further 1% to 15.15% how will the line cycle time and WIP change? Consider a line with two workstations. Workstation 1 has a process time of 10 minutes and SCV off .2. Workstation 2 is prone to rework. Machining requires 15 minutes and the SCV of natural processing time is .1. A defect causes the part to fail during machining. When this happens the product is scrapped and another part is machined. About 15% of casting have this defect. A.) Calculate the mean and SCV of effective process time at workstation 2 B.) Calculate the cycle time and WIP in the line. Assume jobs arrive at the line at a rate of 3 jobs/hour with arrival SCV .5. C.) If the rework percent increases a further 1% to 15.15% how will the line cycle time and WIP change

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts