Question: d. Explain on what situation lot-for-lot sizing technique is not desirable to be adopted. (1 mark) Please solve all parts. The product structure (not using

d. Explain on what situation lot-for-lot sizing technique is not desirable to be adopted. (1 mark)

Please solve all parts.

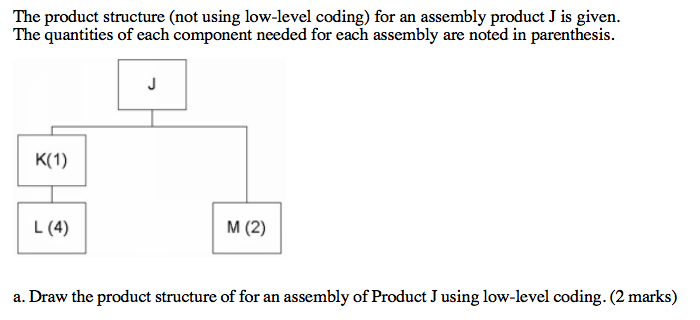

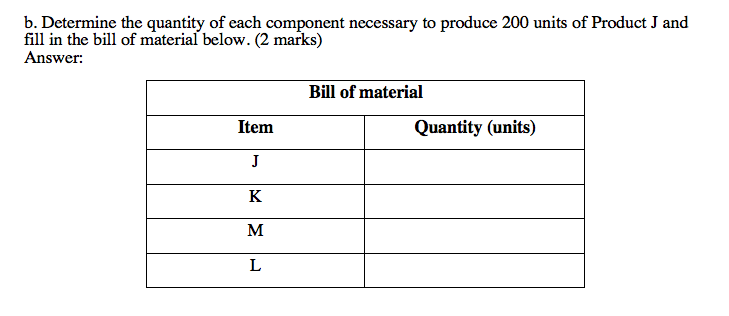

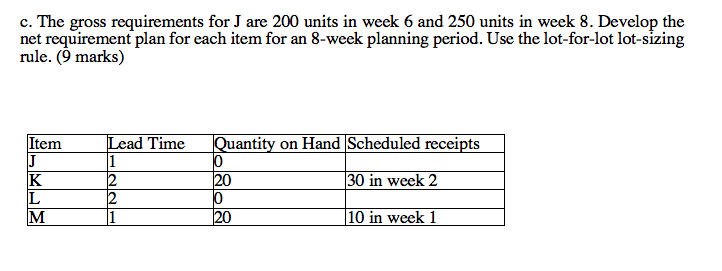

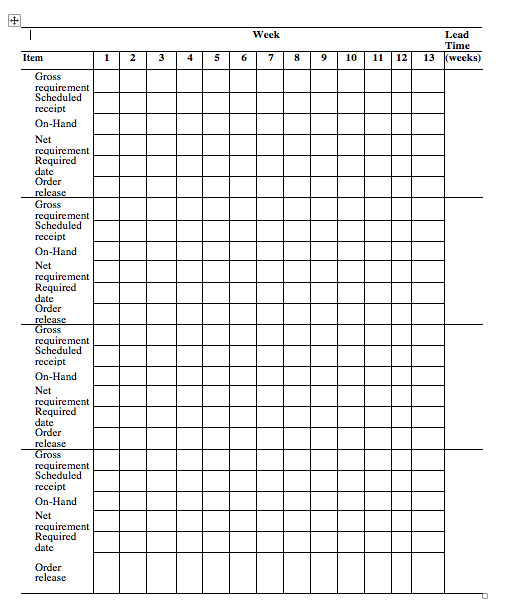

The product structure (not using low-level coding) for an assembly product J is given. The quantities of each component needed for each assembly are noted in parenthesis. K(1) L (4) M (2) a. Draw the product structure of for an assembly of Product J using low-level coding. (2 marks) b. Determine the quantity of each component necessary to produce 200 units of Product J and fill in the bill of material below. (2 marks) Answer: Bill of material Item Quantity (units) J K M L c. The gross requirements for J are 200 units in week 6 and 250 units in week 8. Develop the net requirement plan for each item for an 8-week planning period. Use the lot-for-lot lot-sizing rule. (9 marks) Lead Time 1 Item J K L M NIN 2 2 Quantity on Hand Scheduled receipts 0 20 30 in week 2 0 20 10 in week 1 + Week Lead Time (weeks) Item 1 4 5 6 7 8 9 10 11 12 13 Gross requirement Scheduled receipt On-Hand Net requirement Required date Order release Gross requirement Scheduled receipt On-Hand Net requirement Required date Order release Gross requirement Scheduled receipt On-Hand Net requirement Required date Order release Gross requirement Scheduled receipt On-Hand Net requirement Required date Order releaseStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock