Question: Example MRP: Final Table: 15.14 Consider the part explosion diagram shown in the following figure. Four distinct parts exist and are separately numbered in the

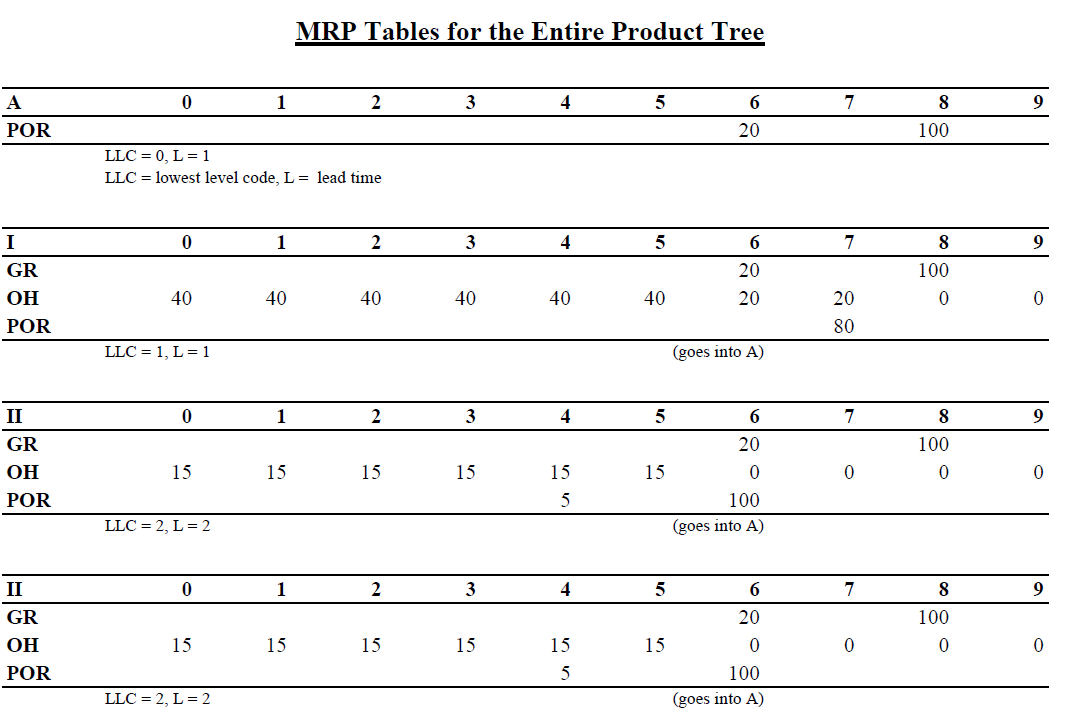

Example MRP:

Final Table:

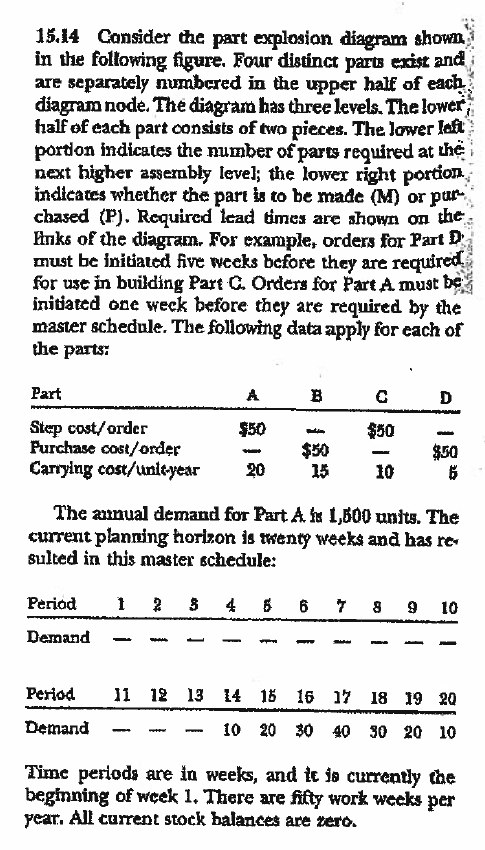

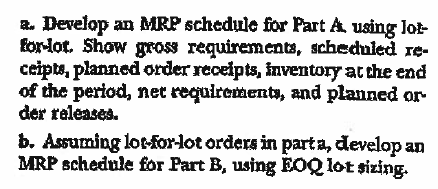

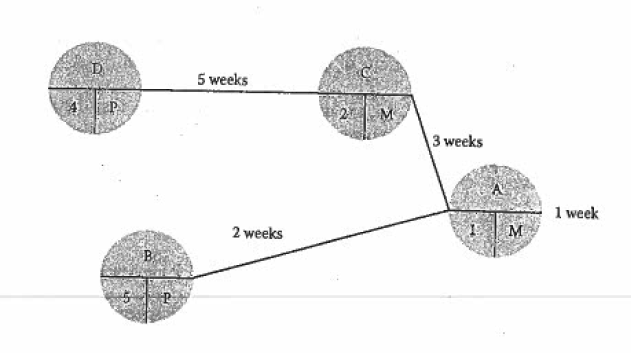

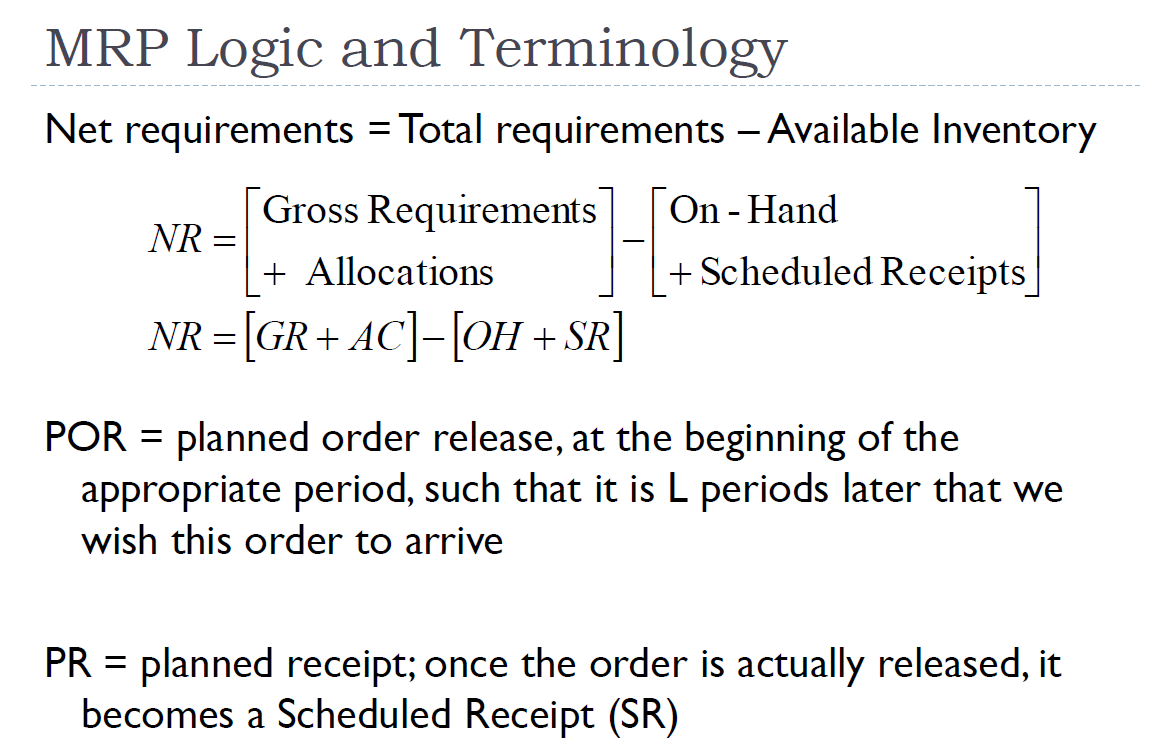

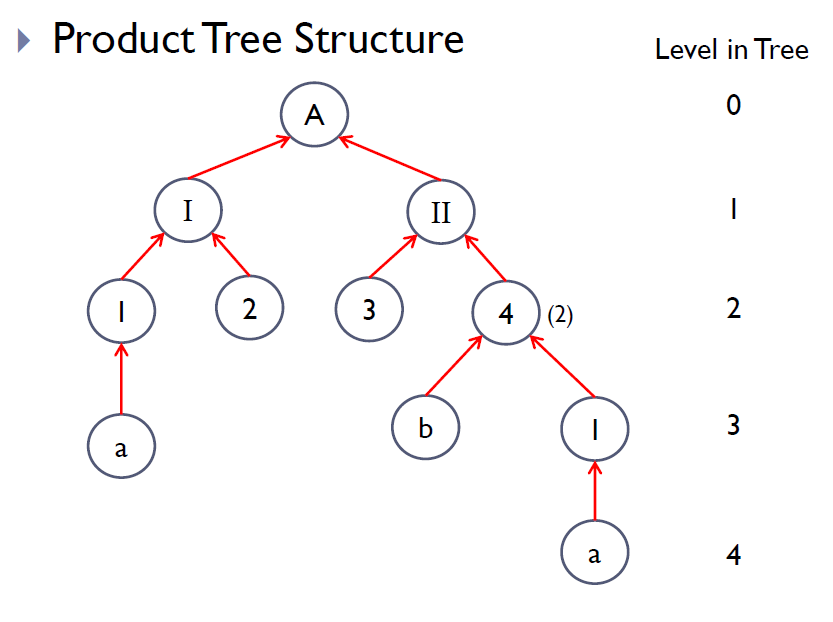

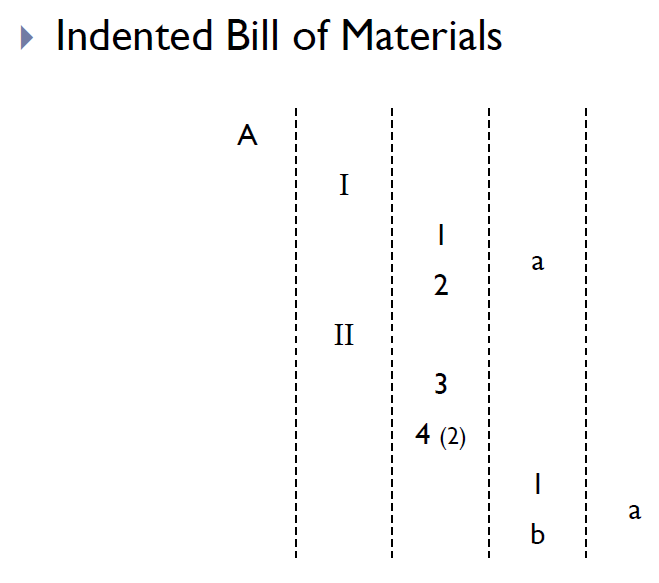

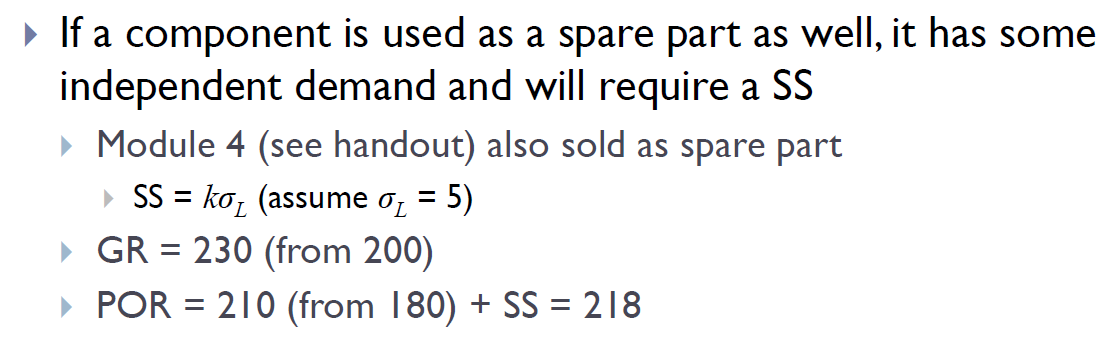

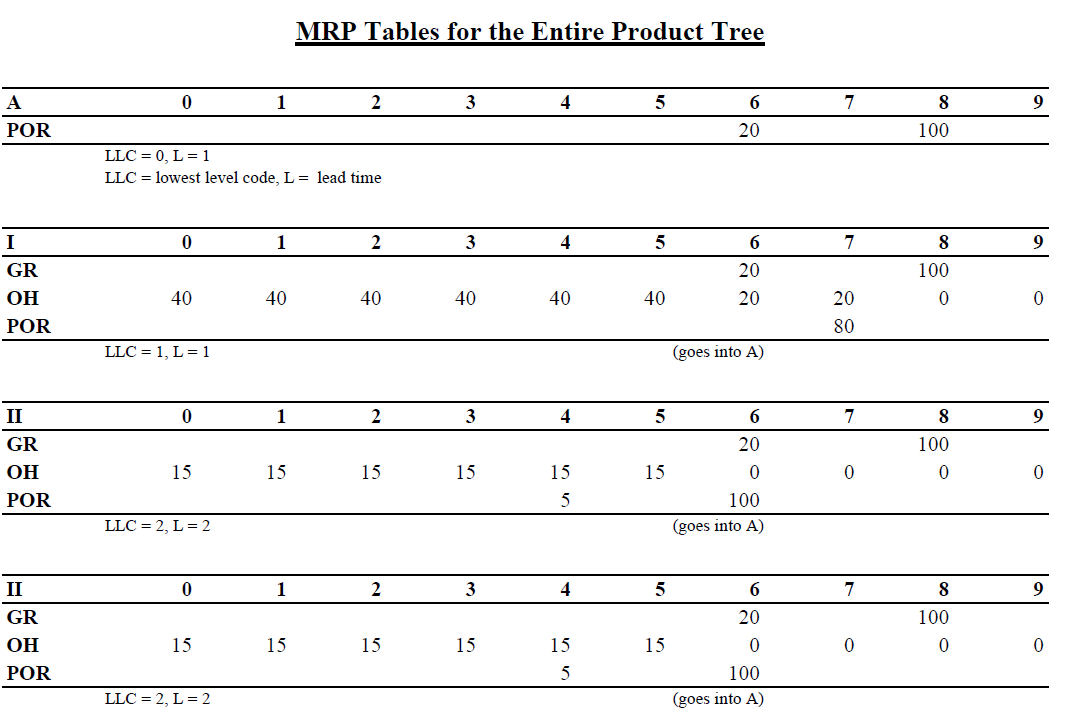

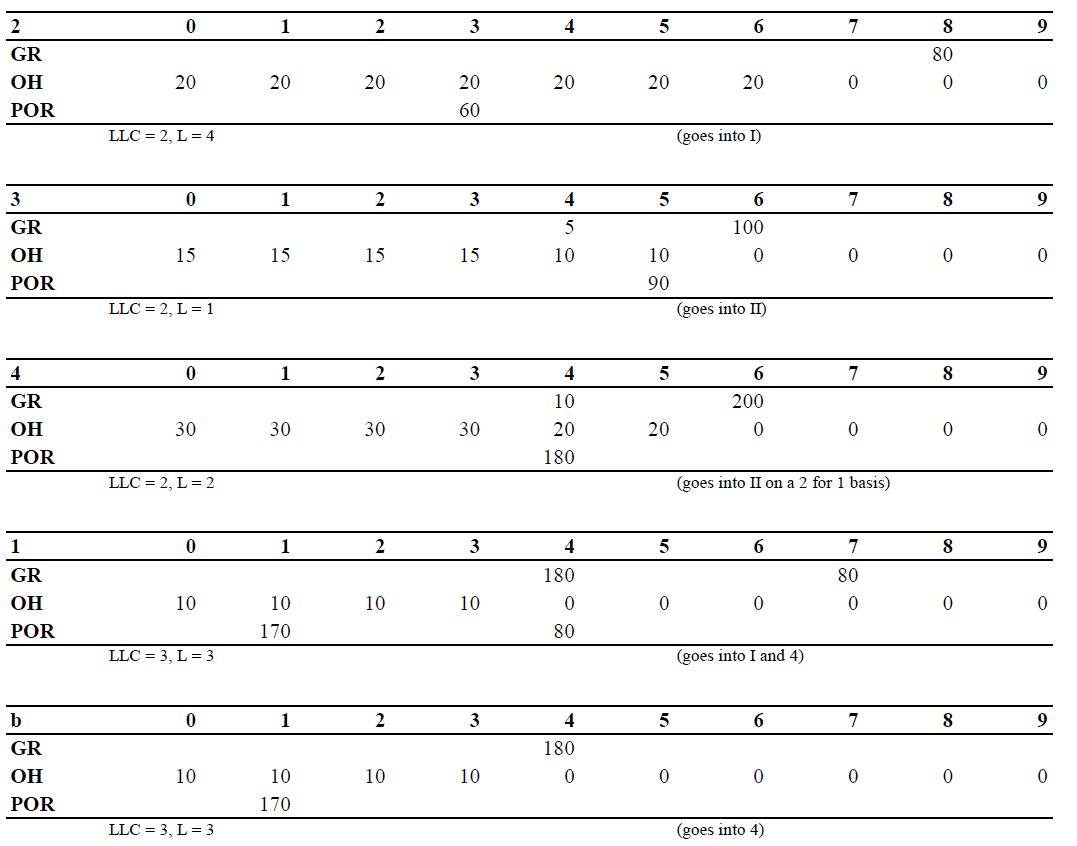

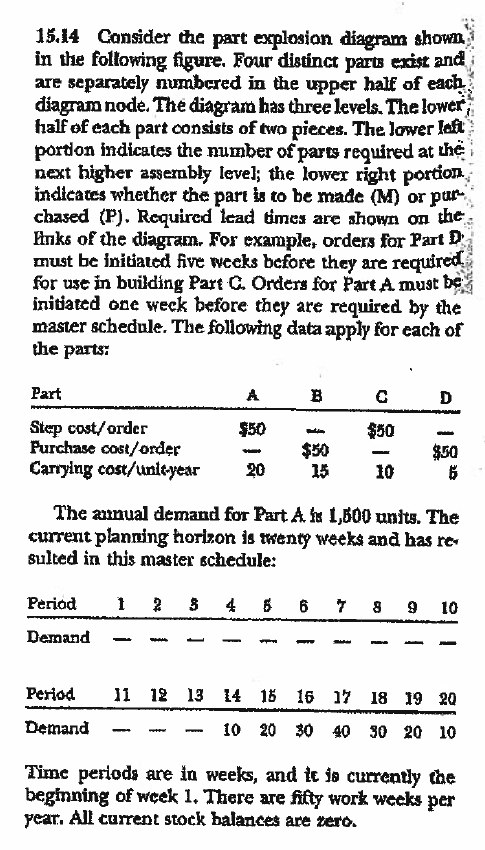

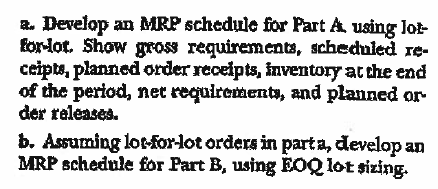

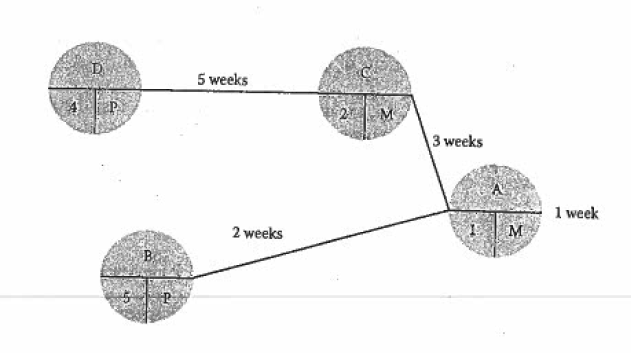

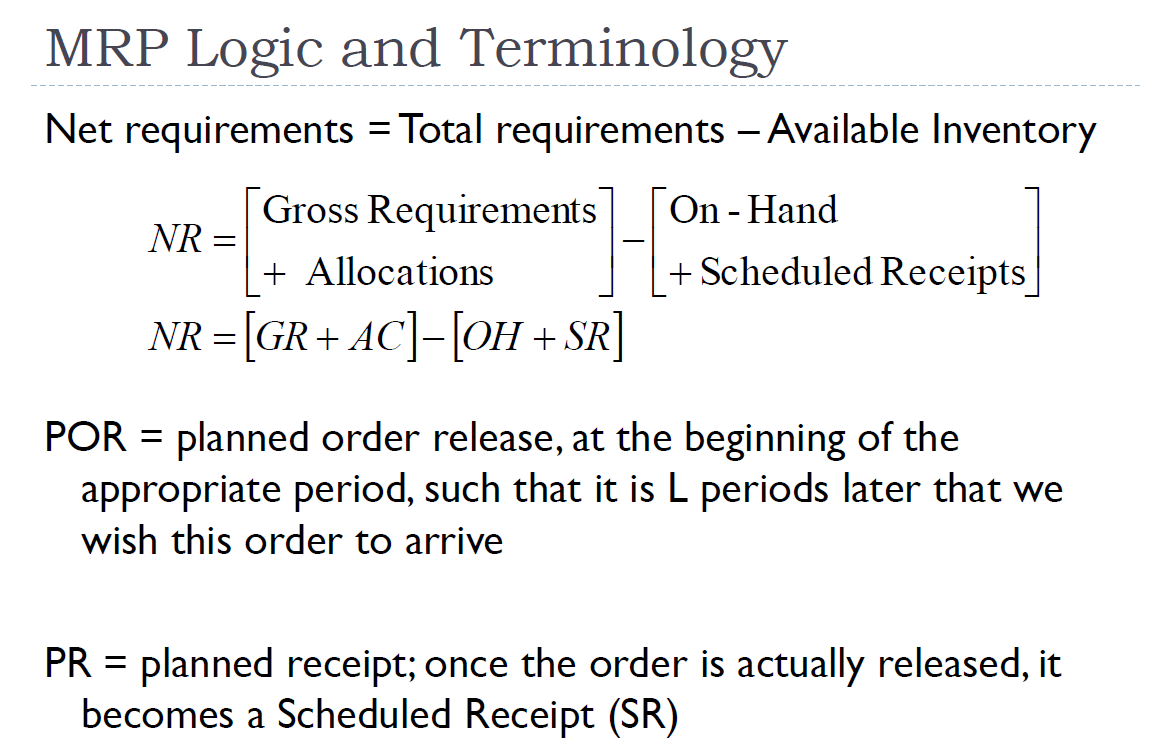

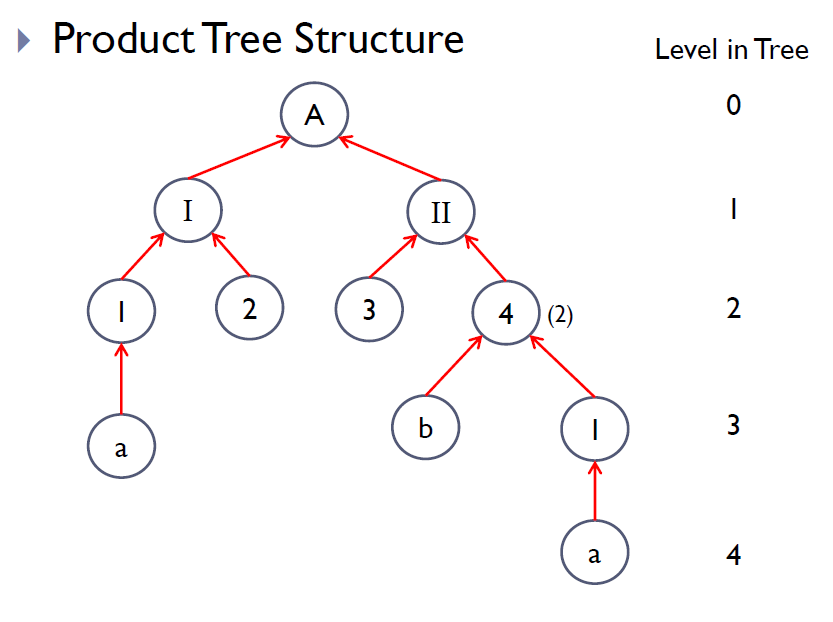

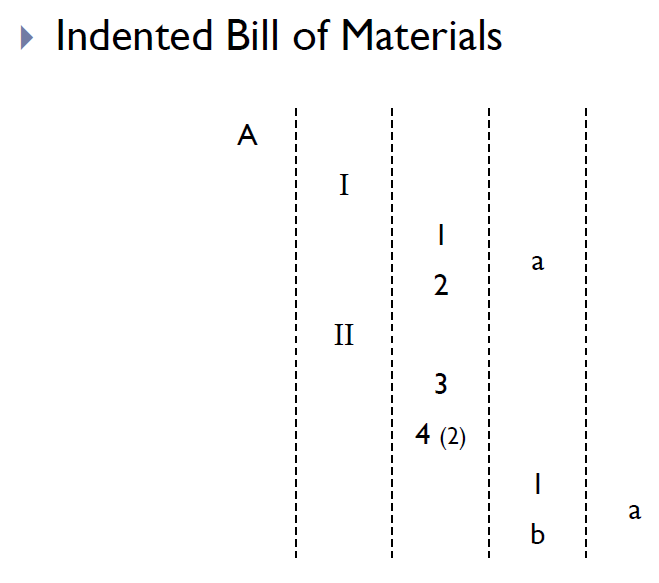

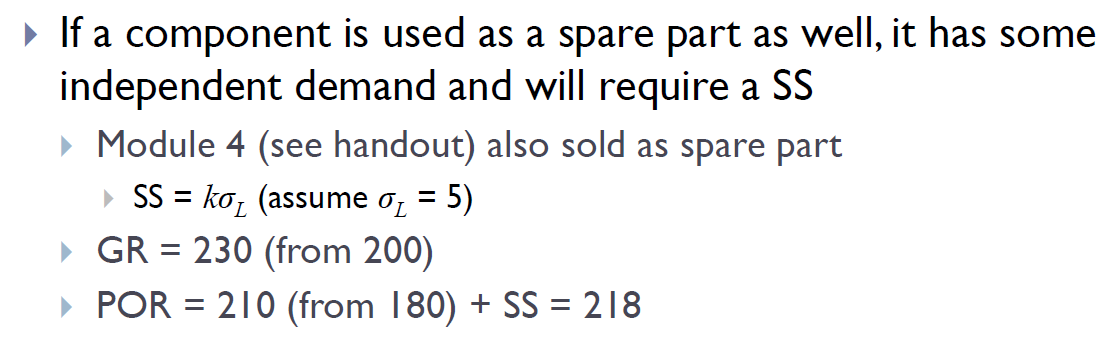

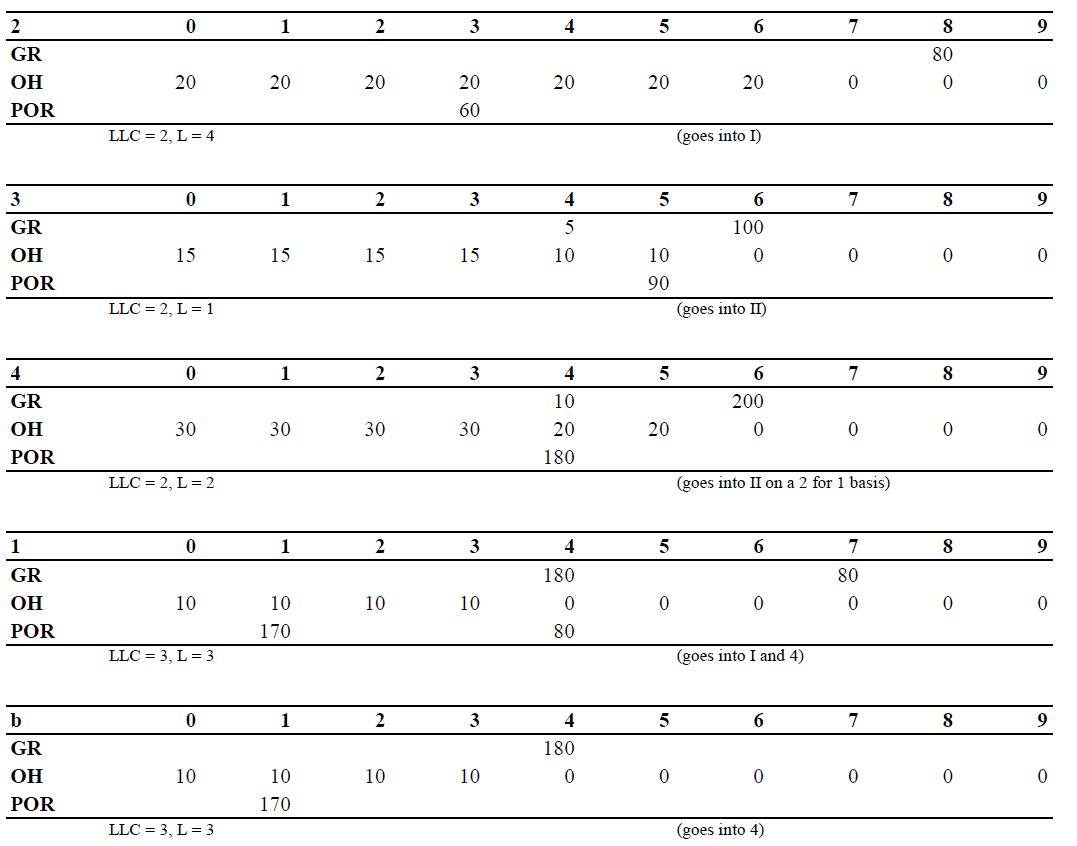

15.14 Consider the part explosion diagram shown in the following figure. Four distinct parts exist and are separately numbered in the upper half of each diagram node. The diagram has three levels. The lower half of each part consists of two pieces. The lower left portion indicates the number of parts required at the next higher assexnbly level; the lower right portion. indicates whether the part is to be made (M) or pur. chased (P). Required Icad times are shown on the Finiks of the diagram. For example, orders for Part D must be initiated five weeks before they are required for use in building Part C. Orders for Part A must be initiated one week before they are required by the master schedule. The following data apply for each of the parts: A B D Part Step cost/order Purchase cost/order Carrying cost/unit-year $50 $50 $50 $50 15 20 10 The annual demand for Part A W 1,600 units. The current planning horizon is twenty weeks and has ro sulted in this master schedule: 1 2 3 4 5 6 7 8 9 10 Period Demand - Period 11 12 13 14 15 16 17 18 19 20 10 20 30 40 30 20 10 Demand Time periods are in weeks, and te is currently the beginning of week 1. There are fifty work weeks per year. All current stock balances are zero. a. Develop an MRP schedule for Part A. using lot- for lot. Show gross requirements, scheduled re- ceipts, planned order receipts, Inventory at the end of the period, ner requirements, and planned or der releases. b. Assuming lor-for-fot orders in parta, develop an MRP schedule for Part B, using EOQ lot sizing. D 5 weeks . M 3 weeks 1 week 2 weeks M B MRP Logic and Terminology Net requirements = Total requirements Available Inventory Gross Requirements On - Hand NR= + Allocations + Scheduled Receipts NR =[GR + AC]-[OH + SR] + + POR = planned order release, at the beginning of the appropriate period, such that it is L periods later that we wish this order to arrive PR = planned receipt; once the order is actually released, it becomes a Scheduled Receipt (SR) Product Tree Structure Level in Tree A 0 I II 2 3 4 (2) 2 b 3 a a 4 Indented Bill of Materials A I a 2 3 4 (2) a b If a component is used as a spare part as well, it has some independent demand and will require a SS Module 4 (see handout) also sold as spare part SS = ko, (assume oy = 5) GR = 230 (from 200) POR = 210 (from 180) + SS = 218 MRP Tables for the Entire Product Tree A 0 1 2 3 4 5 6 7 8 9 POR 20 100 LLC = 0, L = 1 LLC = lowest level code, L = lead time 0 1 2 3 4 5 6 7 8 9 20 100 I GR OH POR 40 40 40 40 40 40 20 0 0 20 80 LLC = 1, L = 1 (goes into A) 0 1 2 3 4 5 7 9 6 20 8 100 II GR OH POR 15 15 15 15 15 0 0 0 0 15 5 100 (goes into A) LLC = 2, L = 2 0 1 2 3 4 7 8 100 II GR OH POR 15 15 15 15 15 5 6 20 15 0 100 (goes into A) 0 0 0 5 LLC = 2, L = 2 0 1 2 3 4 5 6 7 8 9 80 2 GR OH POR 20 20 20 20 20 20 0 0 0 20 60 LLC = 2, L = 4 (goes into I) 0 1 2. 3 4 5 6 7 8 9 3 GR OH POR 5 10 15 15 15 15 0 0 0 100 10 0 90 (goes into II) LLC = 2, L = 1 0 1 2 3 4 5 6 7 8 9 200 4 GR OH POR 30 30 30 30 10 20 180 20 0 0 0 0 LLC = 2, L = 2 (goes into II on a 2 for 1 basis) 1 0 1 2 3 4 5 6 7 8 9 180 80 GR OH POR 10 10 10 0 0 0 0 0 0 10 170 80 LLC = 3, L=3 (goes into I and 4) 0 1 2 3 4 5 6 7 8 9 180 b GR OH POR 10 10 10 10 0 0 0 0 0 170 LLC = 3, L = 3 (goes into 4)