Question: Problem 1 4 . 0 2 3 - Fatigue Design in Gears A spur gearset has 1 7 teeth on the pinion and 5 1

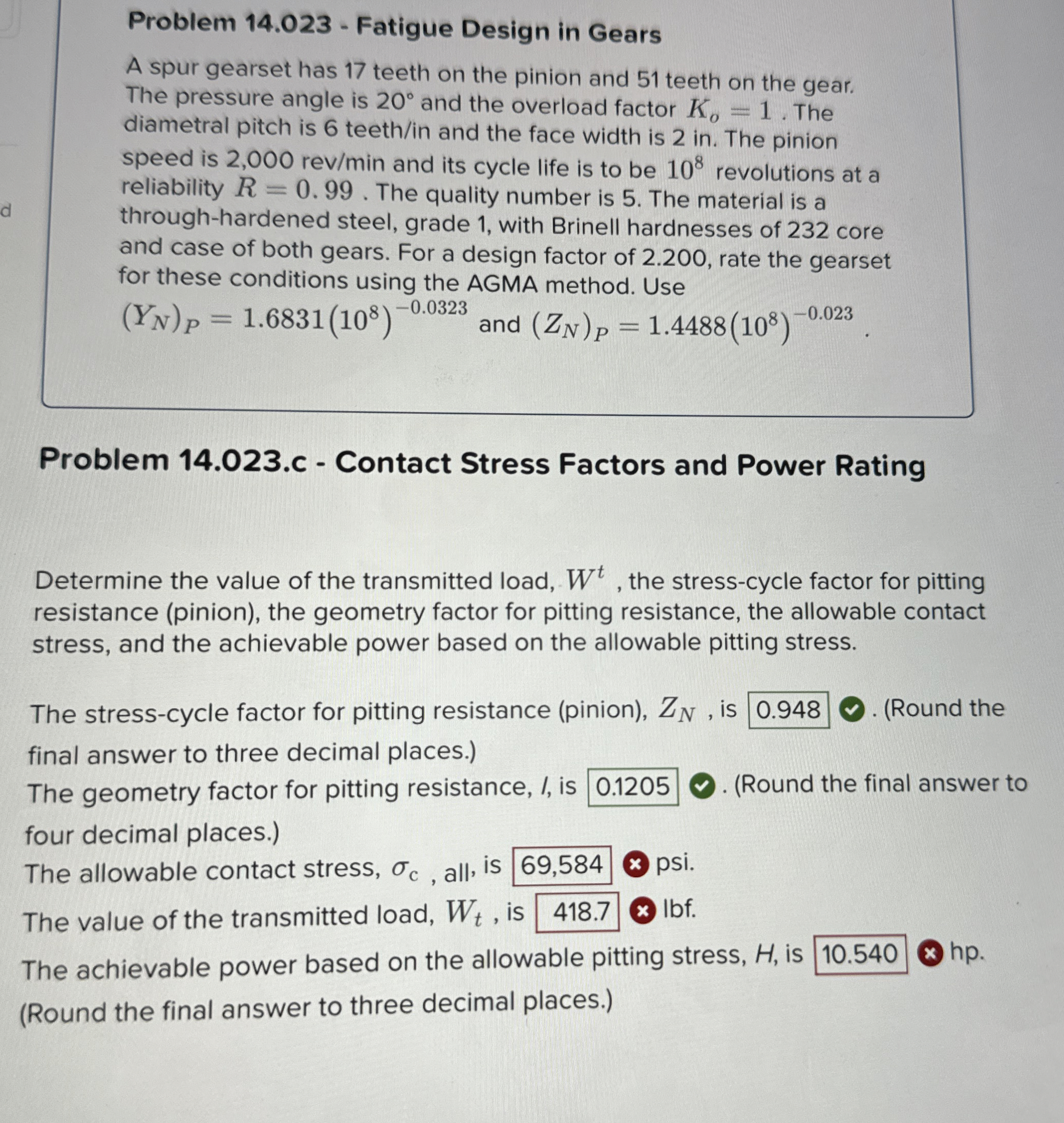

Problem Fatigue Design in Gears

A spur gearset has teeth on the pinion and teeth on the gear.

The pressure angle is and the overload factor The

diametral pitch is teethin and the face width is in The pinion

speed is and its cycle life is to be revolutions at a

reliability The quality number is The material is a

throughhardened steel, grade with Brinell hardnesses of core

and case of both gears. For a design factor of rate the gearset

for these conditions using the AGMA method. Use

and

Problem c Contact Stress Factors and Power Rating

Determine the value of the transmitted load, the stresscycle factor for pitting

resistance pinion the geometry factor for pitting resistance, the allowable contact

stress, and the achievable power based on the allowable pitting stress.

The stresscycle factor for pitting resistance pinion is

Round the

final answer to three decimal places.

The geometry factor for pitting resistance, is

Round the final answer to

four decimal places.

The allowable contact stress, all, is

psi.

The value of the transmitted load, is

Ibf.

The achievable power based on the allowable pitting stress, is

hp

Round the final answer to three decimal places.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock