Question: The project is to design a controller for a mixer. A black dye for making shirts is injected into a stream of water. The injected

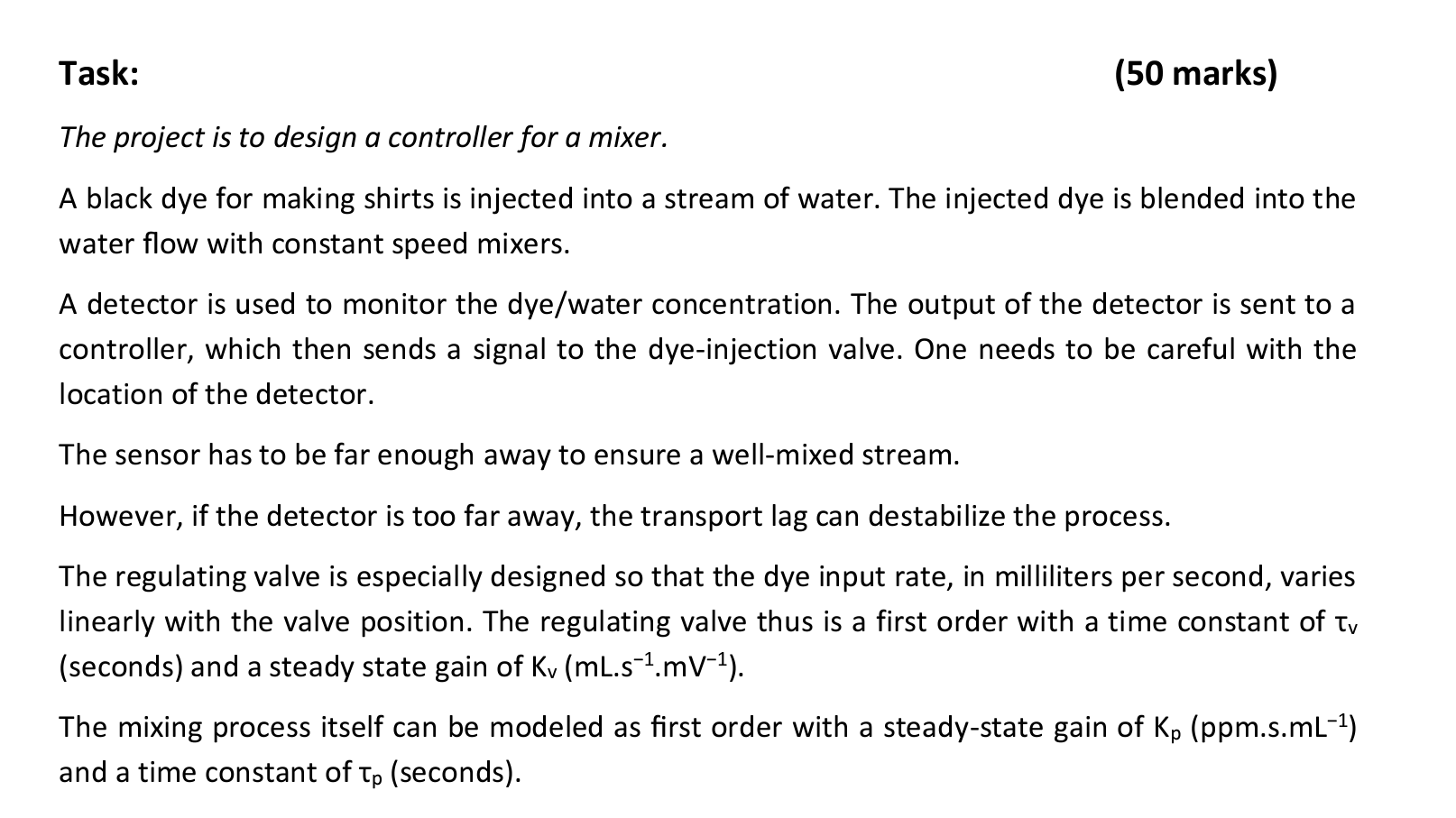

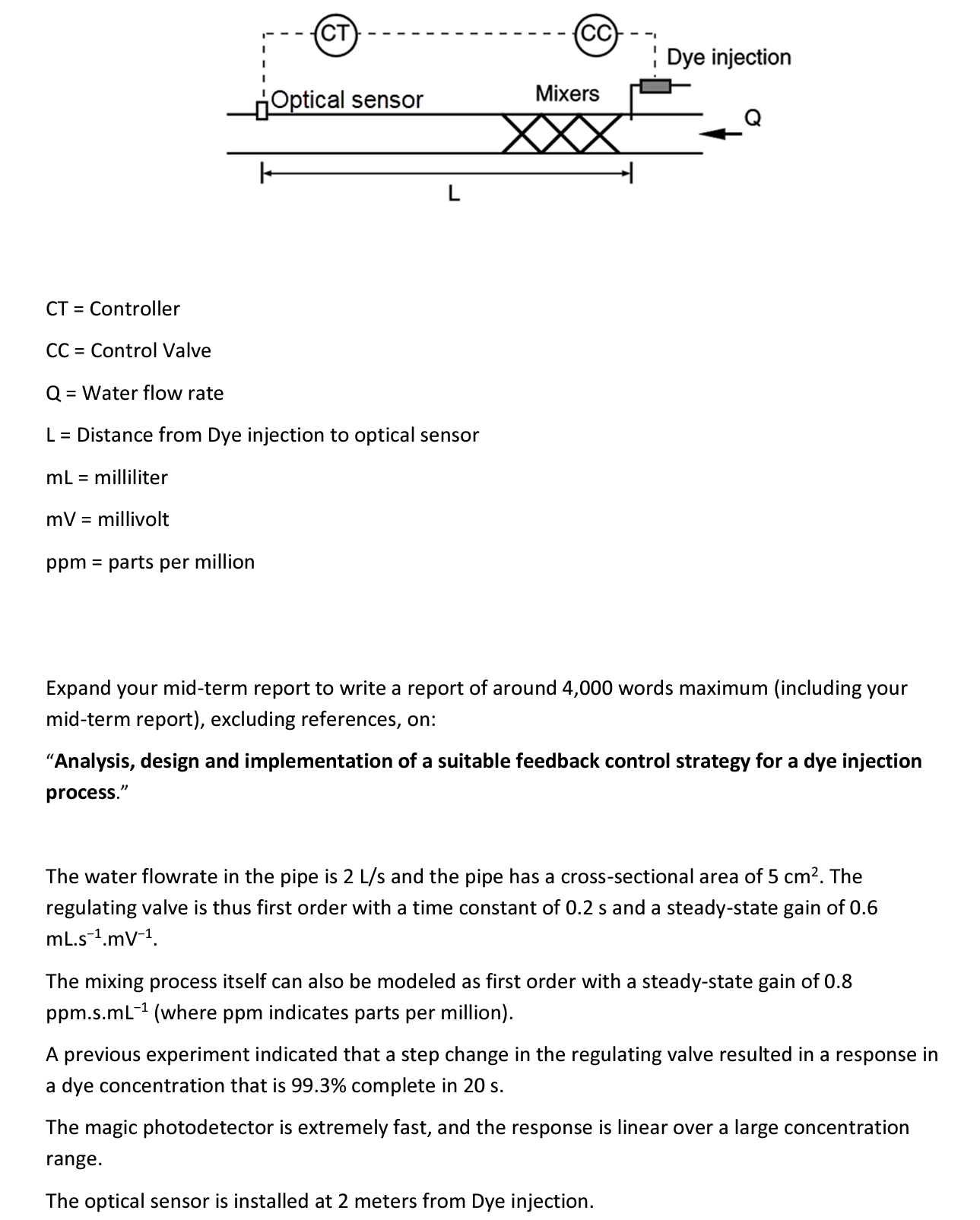

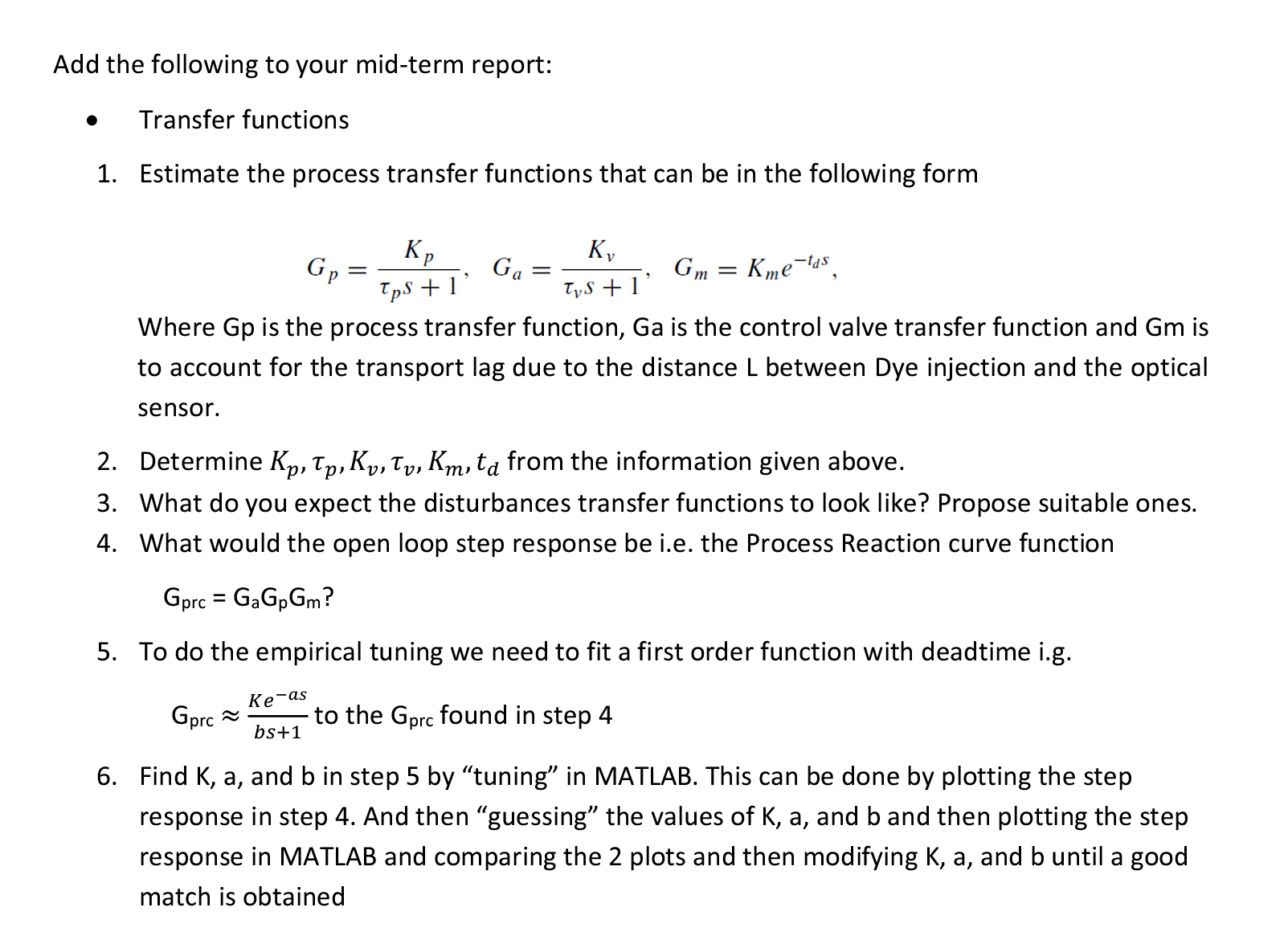

The project is to design a controller for a mixer. A black dye for making shirts is injected into a stream of water. The injected dye is blended into the water flow with constant speed mixers. A detector is used to monitor the dye/water concentration. The output of the detector is sent to a controller, which then sends a signal to the dye-injection valve. One needs to be careful with the location of the detector. The sensor has to be far enough away to ensure a well-mixed stream. However, if the detector is too far away, the transport lag can destabilize the process. The regulating valve is especially designed so that the dye input rate, in milliliters per second, varies linearly with the valve position. The regulating valve thus is a first order with a time constant of v (seconds) and a steady state gain of Kv(mL1mV1). The mixing process itself can be modeled as first order with a steady-state gain of Kp(ppm.smL1) and a time constant of p (seconds). CT= Controller CC= Control Valve Q= Water flow rate L= Distance from Dye injection to optical sensor mL= milliliter mV= millivolt ppm= parts per million Expand your mid-term report to write a report of around 4,000 words maximum (including your mid-term report), excluding references, on: "Analysis, design and implementation of a suitable feedback control strategy for a dye injection process." The water flowrate in the pipe is 2L/s and the pipe has a cross-sectional area of 5cm2. The regulating valve is thus first order with a time constant of 0.2s and a steady-state gain of 0.6 mLs1mV1. The mixing process itself can also be modeled as first order with a steady-state gain of 0.8 ppm.s.mL m1 (where ppm indicates parts per million). A previous experiment indicated that a step change in the regulating valve resulted in a response in a dye concentration that is 99.3% complete in 20s. The magic photodetector is extremely fast, and the response is linear over a large concentration range. The optical sensor is installed at 2 meters from Dye injection. Add the following to your mid-term report: - Transfer functions 1. Estimate the process transfer functions that can be in the following form Gp=ps+1Kp,Ga=vs+1Kv,Gm=Kmetds Where Gp is the process transfer function, Ga is the control valve transfer function and Gm is to account for the transport lag due to the distance L between Dye injection and the optical sensor. 2. Determine Kp,p,Kv,v,Km,td from the information given above. 3. What do you expect the disturbances transfer functions to look like? Propose suitable ones. 4. What would the open loop step response be i.e. the Process Reaction curve function Gprc=GaGpGm? 5. To do the empirical tuning we need to fit a first order function with deadtime i.g. Gprcbs+1Keas to the Gprc found in step 4 6. Find K, a, and b in step 5 by "tuning" in MATLAB. This can be done by plotting the step response in step 4. And then "guessing" the values of K, a, and b and then plotting the step response in MATLAB and comparing the 2 plots and then modifying K, a, and b until a good match is obtained

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts