Question: We are using Loop-Pro software for the simulations and data. Please help with all parts, Thanks! For the Heat Exchanger process, consider a case where

We are using Loop-Pro software for the simulations and data. Please help with all parts, Thanks!

We are using Loop-Pro software for the simulations and data. Please help with all parts, Thanks!

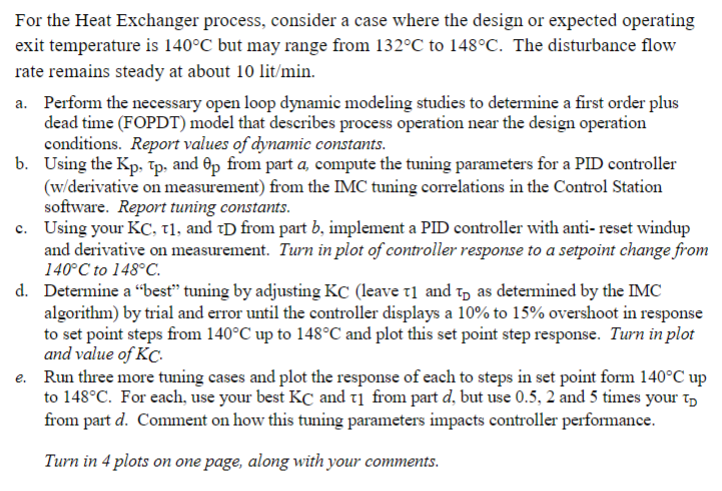

For the Heat Exchanger process, consider a case where the design or expected operating exit temperature is 140C but may range from 132C to 148C. The disturbance flow rate remains steady at about 10lit/min. a. Perform the necessary open loop dynamic modeling studies to determine a first order plus dead time (FOPDT) model that describes process operation near the design operation conditions. Report values of dynamic constants. b. Using the Kp,p, and p from part a, compute the tuning parameters for a PID controller (w/derivative on measurement) from the IMC tuning correlations in the Control Station software. Report tuning constants. c. Using your KCC,1, and D from part b, implement a PID controller with anti- reset windup and derivative on measurement. Turn in plot of controller response to a setpoint change from 140C to 148C. d. Determine a "best" tuning by adjusting KC (leave 1 and D as determined by the IMC algorithm) by trial and error until the controller displays a 10% to 15% overshoot in response to set point steps from 140C up to 148C and plot this set point step response. Turn in plot and value of KC. e. Run three more tuning cases and plot the response of each to steps in set point form 140C up to 148C. For each, use your best KC and 1 from part d, but use 0.5,2 and 5 times your D from part d. Comment on how this tuning parameters impacts controller performance. Turn in 4 plots on one page, along with your comments

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts