Question: We solved this question and wrong answer is below, please solve it again like teacher wants. Our teacher said your answer has wrong parts and

We solved this question and wrong answer is below, please solve it again like teacher wants. Our teacher said your answer has wrong parts and said that :

Unlike what we have seen, the backorder cost seems to be withholding.

(1- service level) = probability of no stock out

So annual backorder cost = (Demand / EOQ) * backorder withholding * (1- service level)

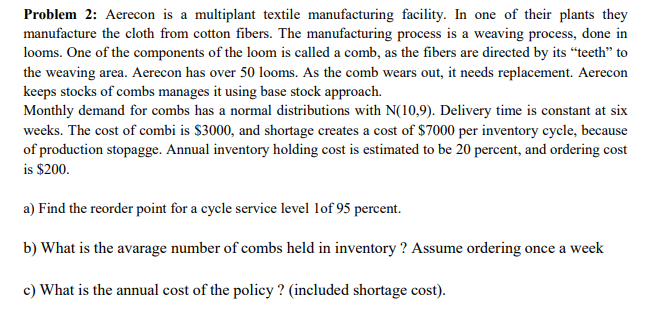

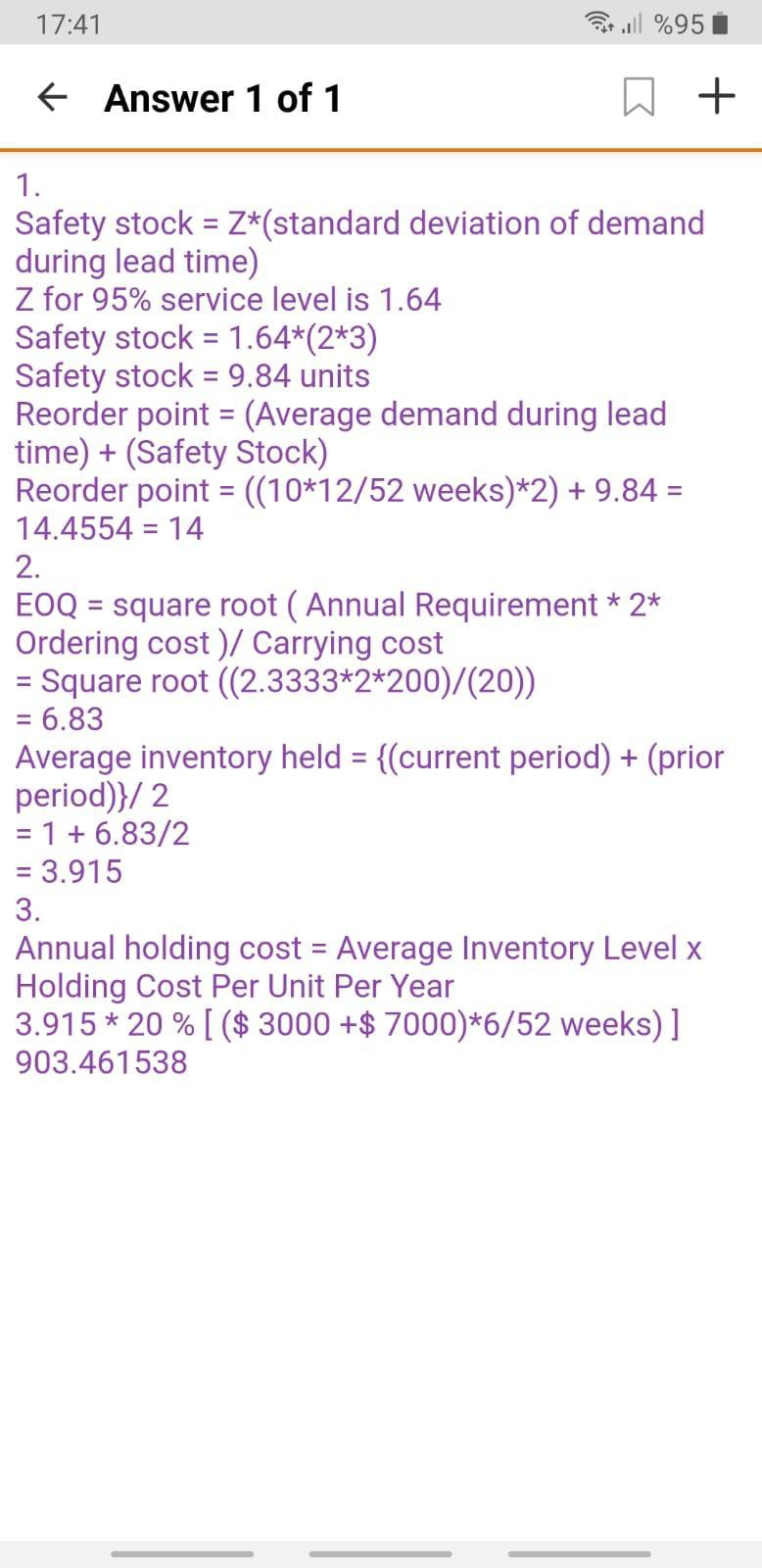

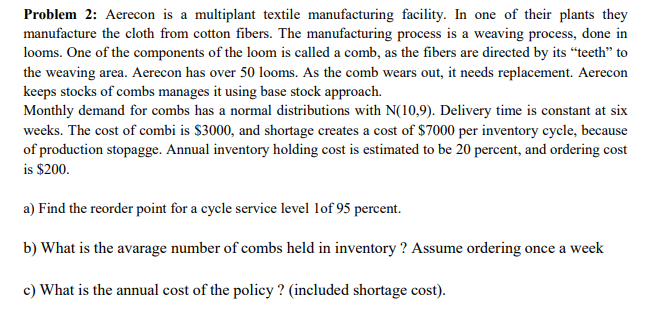

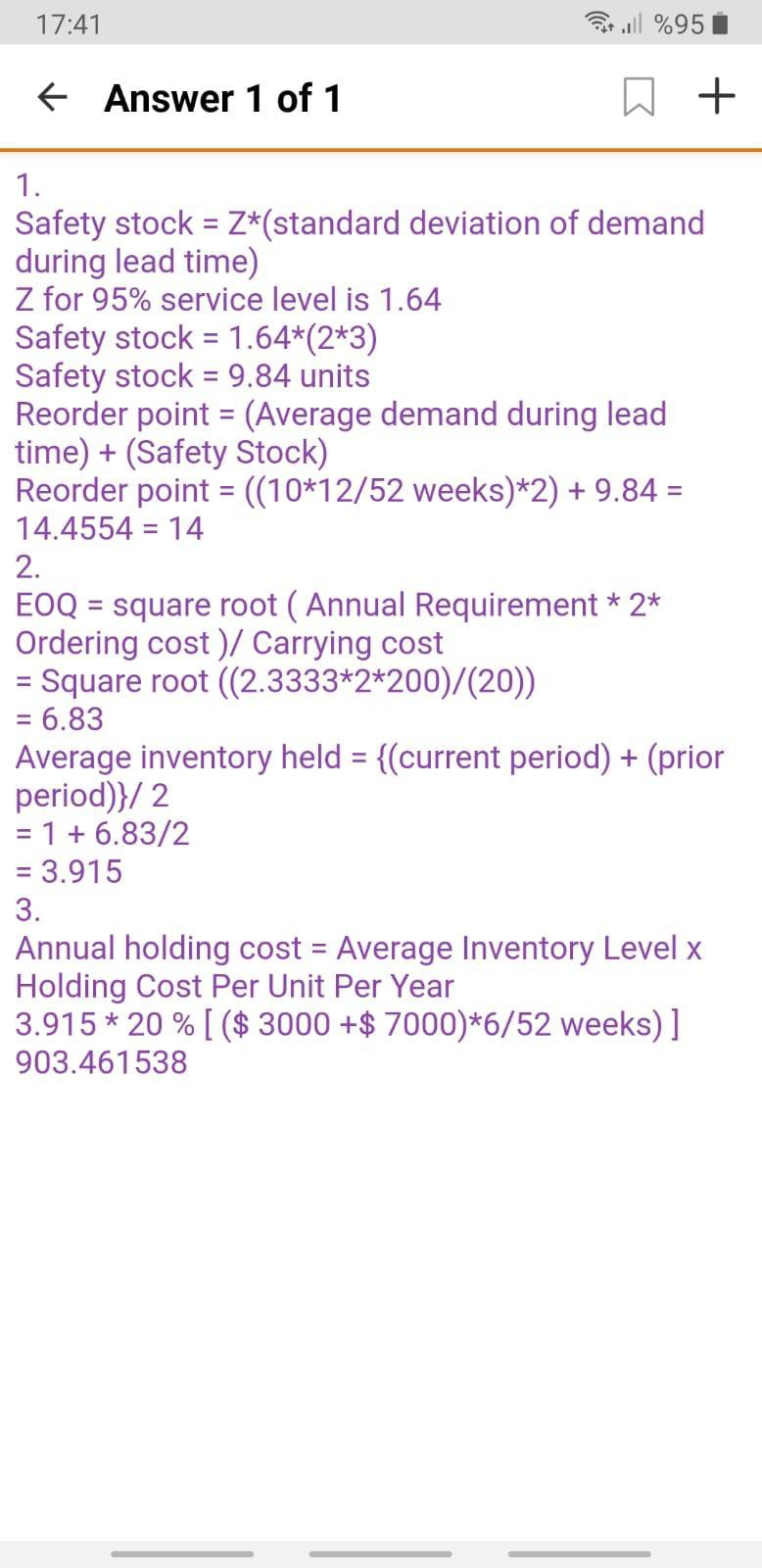

Problem 2: Aerecon is a multiplant textile manufacturing facility. In one of their plants they manufacture the cloth from cotton fibers. The manufacturing process is a weaving process, done in looms. One of the components of the loom is called a comb, as the fibers are directed by its "teeth to the weaving area. Aerecon has over 50 looms. As the comb wears out, it needs replacement. Aerecon keeps stocks of combs manages it using base stock approach. Monthly demand for combs has a normal distributions with N(10,9). Delivery time is constant at six weeks. The cost of combi is $3000, and shortage creates a cost of $7000 per inventory cycle, because of production stopagge. Annual inventory holding cost is estimated to be 20 percent, and ordering cost is $200. a) Find the reorder point for a cycle service level lof 95 percent. b) What is the avarage number of combs held in inventory? Assume ordering once a week c) What is the annual cost of the policy ? (included shortage cost). 17:41 htul %95 + Answer 1 of 1 W + 1. Safety stock = Z*(standard deviation of demand during lead time) Z for 95% service level is 1.64 Safety stock = 1.64*(2*3) Safety stock = 9.84 units Reorder point = (Average demand during lead time) + (Safety Stock) Reorder point = ((10*12/52 weeks)*2) + 9.84 = 14.4554 = 14 2. EOQ = square root ( Annual Requirement * 2* Ordering cost)/ Carrying cost = Square root ((2.3333*2*200)/(20)) = 6.83 Average inventory held = {(current period) + (prior period)}/2 = 1 + 6.83/2 = 3.915 3. Annual holding cost = Average Inventory Level x Holding Cost Per Unit Per Year 3.915 * 20 %[($ 3000 +$ 7000)*6/52 weeks) ] 903.461538 Problem 2: Aerecon is a multiplant textile manufacturing facility. In one of their plants they manufacture the cloth from cotton fibers. The manufacturing process is a weaving process, done in looms. One of the components of the loom is called a comb, as the fibers are directed by its "teeth to the weaving area. Aerecon has over 50 looms. As the comb wears out, it needs replacement. Aerecon keeps stocks of combs manages it using base stock approach. Monthly demand for combs has a normal distributions with N(10,9). Delivery time is constant at six weeks. The cost of combi is $3000, and shortage creates a cost of $7000 per inventory cycle, because of production stopagge. Annual inventory holding cost is estimated to be 20 percent, and ordering cost is $200. a) Find the reorder point for a cycle service level lof 95 percent. b) What is the avarage number of combs held in inventory? Assume ordering once a week c) What is the annual cost of the policy ? (included shortage cost). 17:41 htul %95 + Answer 1 of 1 W + 1. Safety stock = Z*(standard deviation of demand during lead time) Z for 95% service level is 1.64 Safety stock = 1.64*(2*3) Safety stock = 9.84 units Reorder point = (Average demand during lead time) + (Safety Stock) Reorder point = ((10*12/52 weeks)*2) + 9.84 = 14.4554 = 14 2. EOQ = square root ( Annual Requirement * 2* Ordering cost)/ Carrying cost = Square root ((2.3333*2*200)/(20)) = 6.83 Average inventory held = {(current period) + (prior period)}/2 = 1 + 6.83/2 = 3.915 3. Annual holding cost = Average Inventory Level x Holding Cost Per Unit Per Year 3.915 * 20 %[($ 3000 +$ 7000)*6/52 weeks) ] 903.461538