Question: WS No 1 : Diffusion The steady - state diffusion flux through a metal plate is 5 . 4 1 0 - 1 0 k

WS No: Diffusion The steadystate diffusion flux through a metal plate is s at a temperature

of and when the concentration gradient is Calculate the diffusion flux

at for the same concentration gradient and assuming an activation energy for

diffusion of

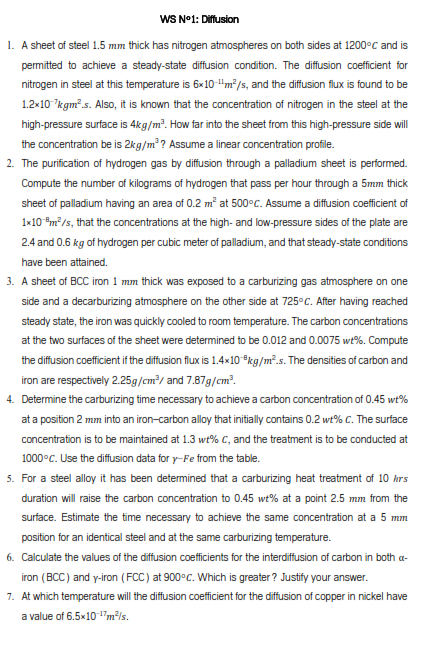

A sheet of steel mm thick has nitrogen atmospheres on both sides at and is

permitted to achieve a steadystate diffusion condition. The diffusion coefficient for

nitrogen in steel at this temperature is and the diffusion flux is found to be

Also, it is known that the concentration of nitrogen in the steel at the

highpressure surface is How far into the sheet from this highpressure side will

the concentration be is Assume a linear concentration profile.

The purification of hydrogen gas by diffusion through a palladium sheet is performed.

Compute the number of kilograms of hydrogen that pass per hour through a mm thick

sheet of palladium having an area of at Assume a diffusion coefficient of

that the concentrations at the high and lowpressure sides of the plate are

and kg of hydrogen per cubic meter of palladium, and that steadystate conditions

have been attained.

A sheet of BCC iron mm thick was exposed to a carburizing gas atmosphere on one

side and a decarburizing atmosphere on the other side at After having reached

steady state, the iron was quickly cooled to room temperature. The carbon concentrations

at the two surfaces of the sheet were determined to be and Compute

the diffusion coefficient if the diffusion flux is The densities of carbon and

iron are respectively and

Determine the carburizing time necessary to achieve a carbon concentration of

at a position mm into an ironcarbon alloy that initially contains The surface

concentration is to be maintained at and the treatment is to be conducted at

Use the diffusion data for from the table.

For a steel alloy it has been determined that a carburizing heat treatment of hrs

duration will raise the carbon concentration to at a point mm from the

surface. Estimate the time necessary to achieve the same concentration at a mm

position for an identical steel and at the same carburizing temperature.

Calculate the values of the diffusion coefficients for the interdiffusion of carbon in both

iron BCC and iron FCC at Which is greater? Justify your answer.

At which temperature will the diffusion coefficient for the diffusion of copper in nickel have

a value of

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock