Question: Design of a Wire Drawing Process. Write a program that will effectively computerize the solution to solving Example 8-4. The program should ask the user

Design of a Wire Drawing Process. Write a program that will effectively computerize the solution to solving Example 8-4. The program should ask the user to provide a value of the final diameter for the wire (e.g., 0.20 cm). The program should assume a reasonable value for the initial diameter (d0) (e.g., 0.40 cm), and calculate the extent of cold work using the proper formula. Assume that the user has access to the yield strength versus % cold work curve. The user is then asked to enter the value of the yield strength for 0% cold work. Use this value to calculate the forces needed for drawing and the stress acting on the wire as it comes out of the die. The program should then ask the user to provide the value of the yield strength of the wire for the amount of cold work calculated for the assumed initial diameter and the final diameter needed. As in Example 8-4, the program should repeatthese calculations until obtaining a value of d0 that will be acceptable.

Example 8–4

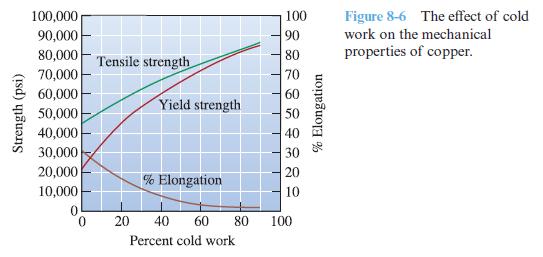

Design a process to produce 0.20-in.-diameter copper wire. The mechanical properties of the copper to be considered are shown in Figure 8-6.

Strength (psi) 100,000 90,000 80,000 70,000 60,000 50,000 40,000 30,000 20,000 10,000 0 0 Tensile strength Yield strength % Elongation 100 90 80 70 60 50 40 30 20 10 20 40 60 80 100 Percent cold work % Elongation Figure 8-6 The effect of cold work on the mechanical properties of copper.

Step by Step Solution

3.48 Rating (165 Votes )

There are 3 Steps involved in it

The design is as follows i Determine the thickness of the wire at the yield point t using ... View full answer

Get step-by-step solutions from verified subject matter experts