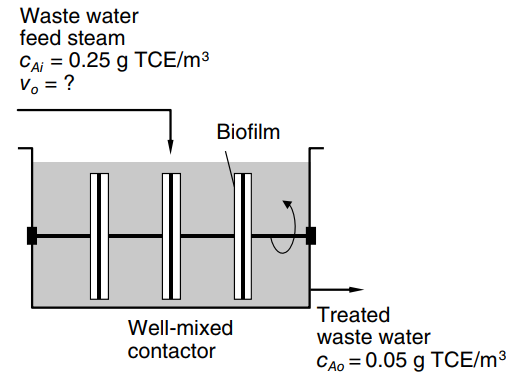

A bio film reactor with a well-mixed liquid phase shown below will be used to treat wastewater

Question:

a. What volumetric flow rate of wastewater is allowed to enter the reactor? The temperature of the process is constant at 20°C.

b. What is the concentration of TCE in the biofilm at the point where the biofilm is attached to the surface? What fraction of 100 µm thickness of the bio film is utilized?

Potentially useful data*: kTCE = 4.3 1 s-1 (first-order rate constant for TCE in biofilm); DTCE-biofilm = 9.03 × 10-10 m2/s (diffusion coefficient TCE in biofilm).

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Fundamentals Of Momentum Heat And Mass Transfer

ISBN: 9781118947463

6th Edition

Authors: James Welty, Gregory L. Rorrer, David G. Foster

Question Posted: